A kind of flocking paper for heat transfer and its production process

A technology of thermal transfer and flocking paper, which is applied in the field of flocking paper, can solve problems such as difficulty in controlling the amount of hot-melt powder sprayed evenly, the influence of fluff bonding fastness, and the inability to achieve printing effects, etc., to achieve accurate color matching by computer , fine color performance, excellent bonding fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

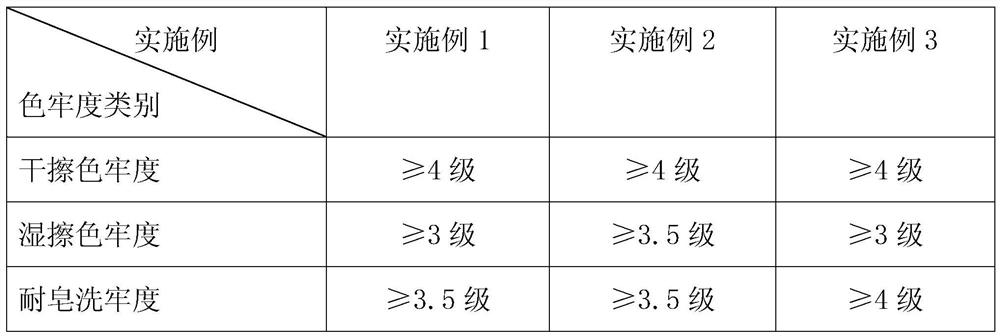

Examples

preparation example Construction

[0028] The preparation method of thermal transfer adhesive is: add silicone leveling agent and polyether defoamer to water-based polyurethane adhesive in turn, stir evenly, then add PDF thickener to thicken under high-speed stirring To the desired viscosity, filter through a 200-mesh filter and set aside.

[0029] Among them, the water-based polyurethane adhesive is ZS-751 water-based polyurethane adhesive independently developed by Zhang's Flocking Material Equipment (Shenzhen) Co., Ltd., and the silicone leveling agent is YZ-1500 produced by Jiaxing Yuanzhi Chemical Co., Ltd. Silicone leveling agent; polyether defoamer is XAMA-3c polyether defoamer produced by German Bayer Chemical; PDF thickener is a conventional commercially available product.

[0030] The flocking adhesive includes the following raw materials in parts by weight: 45-55 parts of water-based acrylic adhesive, 45-55 parts of deionized water, 0.2-0.6 parts of silicone leveling agent, 0.3-0.3 parts of polyether...

Embodiment 1

[0050] A kind of flocking paper for thermal transfer, comprising flocking base paper, flocking adhesive, fluff layer and thermal transfer adhesive arranged in sequence from bottom to top.

[0051] The fluff layer is arranged by multiple fluffs to form various patterns.

[0052] The thermal transfer adhesive includes the following raw materials in parts by weight: 90 parts of water-based polyurethane adhesive, 0.6 part of silicone leveling agent, 0.3 part of polyether defoamer, and 0.5 part of PDF thickener.

[0053] The preparation method of thermal transfer adhesive is: add silicone leveling agent and polyether defoamer to water-based polyurethane adhesive in turn, stir evenly, then add PDF thickener to thicken under high-speed stirring To the desired viscosity, filter through a 200-mesh filter and set aside.

[0054] Among them, the water-based polyurethane adhesive is ZS-751 water-based polyurethane adhesive independently developed by Zhang's Flocking Material Equipment (S...

Embodiment 2

[0075] A kind of flocking paper for thermal transfer, comprising flocking base paper, flocking adhesive, fluff layer and thermal transfer adhesive arranged in sequence from bottom to top.

[0076] The fluff layer is arranged by multiple fluffs to form various patterns.

[0077] The thermal transfer adhesive includes the following raw materials in parts by weight: 110 parts of water-based polyurethane adhesive, 0.2 part of silicone leveling agent, 0.7 part of polyether defoamer, and 0.2 part of PDF thickener.

[0078] The preparation method of thermal transfer adhesive is: add silicone leveling agent and polyether defoamer to water-based polyurethane adhesive in turn, stir evenly, then add PDF thickener to thicken under high-speed stirring To the desired viscosity, filter through a 200-mesh filter and set aside.

[0079] Among them, the water-based polyurethane adhesive is ZS-751 water-based polyurethane adhesive independently developed by Zhang's Flocking Material Equipment (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com