Aqueous UV primer for tempered glass

A tempered glass, water-based technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems that affect the promotion of colorless UV coatings, unstable initiators, and coatings that affect product aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Preparation of Surface Modified Nano-SiO2 Containing Double Bonds

[0053] Take 3.0g of nano silicon dioxide and 3.1g of isophorone diisocyanate and disperse in 90mL of anhydrous toluene, disperse in ultrasonic wave for 10min after evacuating and filling with nitrogen, and disperse at 90 o C reacted for 6h. After the reaction is finished, wash with anhydrous toluene, disperse the product in anhydrous toluene and ultrasonically disperse for 10 minutes, then add 1.5 hydroxy butyl acrylate dropwise, and protect with nitrogen for 90 o C reacted for 48h. After the reaction is finished, it is separated by centrifugation, and the physical adsorption on the surface is washed away by using toluene, so as to obtain nano silicon dioxide with surface modification containing double bonds.

[0054] Waterborne urethane acrylate is prepared in the laboratory, and the required raw materials are commercially available. The preparation method is as follows:

[0055] At 40-50°C, add 30...

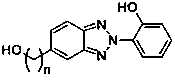

Embodiment 1

[0057] At 40-50°C, add 30 parts of 1,6-hexamethylene diisocyanate and 20 parts of isophorone diisocyanate, wherein the catalyst is 0.02-0.03% of the total mass of polyethylene glycol monomethyl ether and isocyanate compounds, and then Add 20 parts of glycerin and pentaerythritol tetrakis (3-mercaptopropionic acid) ester (the molar number of isocyanate is similar to the hydroxyl value of alcohol and thiol) at 50-60°C, and continue the reaction until the characteristic absorption peak of NCO measured by Fourier transform infrared transform spectrometer disappears 90% time lost, add 5 parts of benzotriazole derivatives, continue the reaction until the NCO characteristic absorption peak measured by Fourier transform infrared transform spectrometer disappears, and obtain the modified polyurethane acrylate emulsion.

[0058] 30 parts of deionized water, 0.5 parts of nano-silica containing double bonds on the surface, 0.3 parts of acetoisophorone, added to GFJ-0.4 high-speed dispersin...

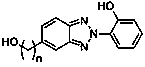

Embodiment 2

[0061] At 40-50°C, mix 30 parts of toluene diisocyanate and 20 parts of isophorone diisocyanate, wherein the catalyst is 0.02-0.03% of the total mass of polyethylene glycol monomethyl ether and isocyanate compounds, and then at 50-60°C Add 20 parts of polyethylene glycol, pentaerythritol tetrakis (3-mercaptopropionic acid) ester (the molar number of isocyanate is similar to the hydroxyl value of alcohol and mercaptan), and continue to react until the NCO characteristic absorption peak measured by Fourier transform infrared transform spectrometer disappears for 90 % time lost, add 5 parts of benzotriazole derivatives, continue to react until the NCO characteristic absorption peak measured by Fourier transform infrared transform spectrometer disappears, and obtain modified polyurethane acrylate emulsion.

[0062] 30 parts of deionized water, 0.5 parts of nano-silica containing double bonds on the surface, 0.3 parts of acetoisophorone, added to GFJ-0.4 high-speed dispersing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com