High-precision time-difference single-pulse ultrasonic flowmeter system and method for measuring flow

An ultrasonic and single-pulse technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc., can solve the problems of increased number of devices, complex systems, complex circuits, etc., to improve control accuracy, simple and economical system, The effect of emitting large energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings:

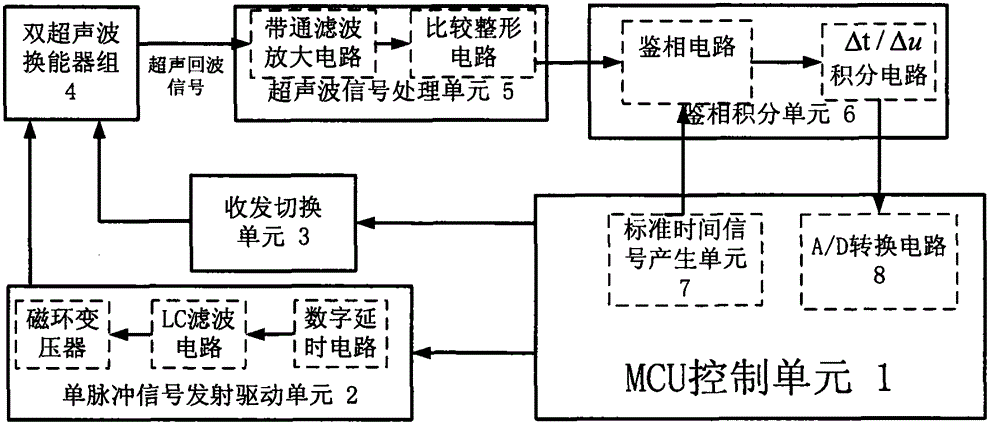

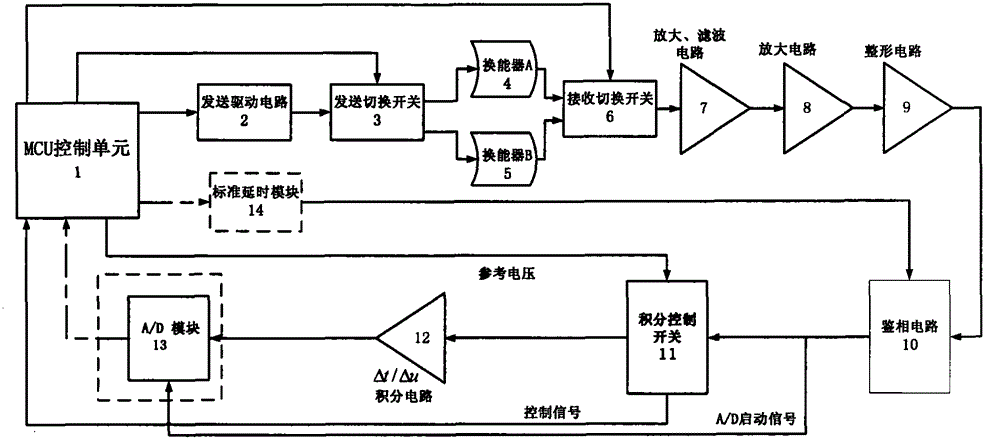

[0039] see figure 1 , based on the schematic diagram of the ultrasonic flowmeter system of the present invention, the system includes: MCU control unit 1, single pulse signal transmission drive unit 2, transceiver switching unit 3, ultrasonic transducer group 4, ultrasonic signal processing unit 5 and phase detection Integral Unit 6, the

[0040] The MCU control unit is used to send control signals to the transceiver switching unit and the single pulse signal transmitting drive unit, and

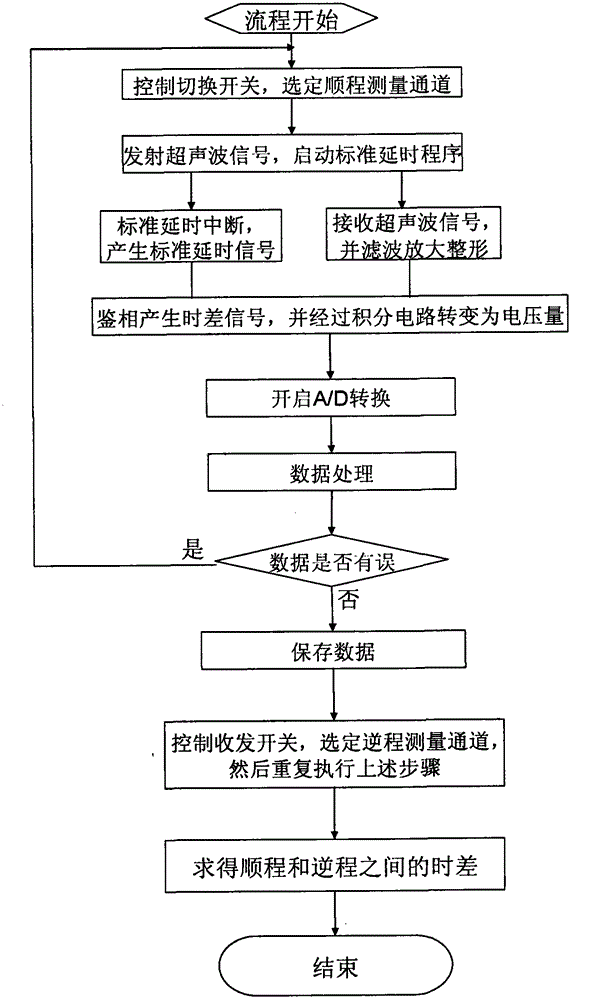

[0041] Send the standard delay signal to the phase detection and integration unit and use the measured forward travel time and reverse travel time of the ultrasonic wave to calculate the time difference between the reverse travel and forward travel of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com