Lignin/polyvinyl alcohol composite material and preparation method thereof

A technology of polyvinyl alcohol and composite materials, applied in the field of polymer materials, can solve the problems of low toughness, low composite film strength, and poor compatibility of PVA composite films, and achieve improved interface compatibility, low cost, and promotion of dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

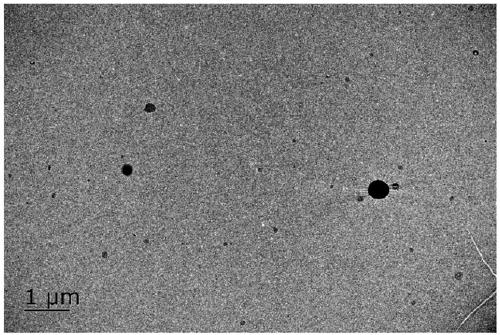

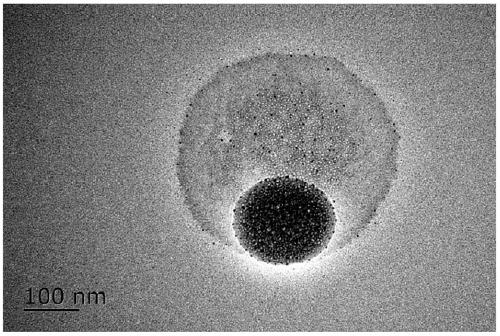

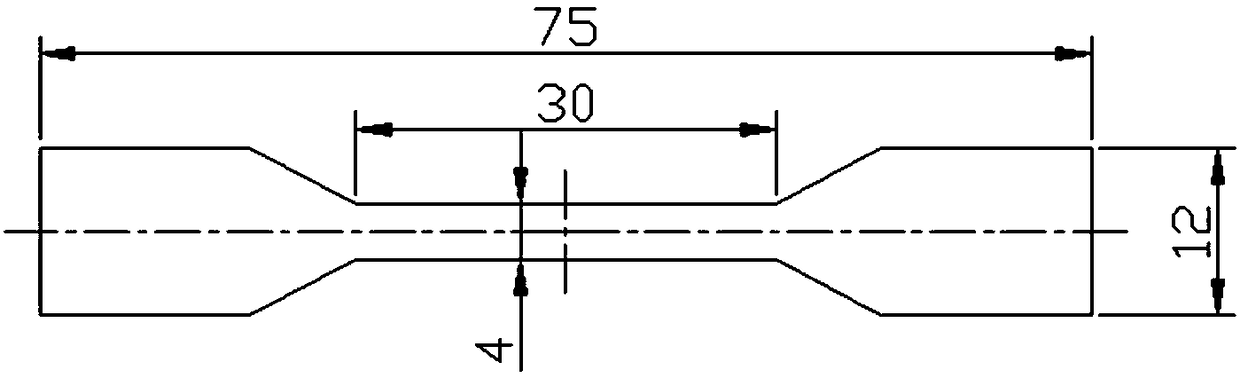

Image

Examples

Embodiment 1

[0030] Parts by mass, g / mL, take 4.975 parts by mass of polyvinyl alcohol, 0.025 parts by mass of lignin, 0.025 parts by mass of sodium chloride, and add 100 parts by volume of water; at a heating temperature of 90°C, stir mechanically at 50 rpm for 3 hours, and fully dissolve The mixed solution of the mixed solution is cast into a film, and the lignin / polyvinyl alcohol composite material can be obtained after the water is naturally volatilized at room temperature. Wherein, the selected polyvinyl alcohol Mw=130000g / mol, and the degree of hydrolysis is 99%. The selected lignin is lignosulfonic acid, a by-product of sulfite pulping.

Embodiment 2

[0032] Parts by mass, g / mL, take 4.95 parts by mass of polyvinyl alcohol, 0.05 parts by mass of lignin, 0.05 parts by mass of sodium chloride, and add 100 parts by volume of water; at a heating temperature of 80°C, stir mechanically at 100 rpm for 2 hours, and fully dissolve The mixed solution of the mixed solution is cast into a film, and the lignin / polyvinyl alcohol composite material can be obtained after the water is naturally volatilized at room temperature. Wherein, the selected polyvinyl alcohol Mw=30000g / mol, and the degree of hydrolysis is 99%. The selected lignin is lignosulfonic acid, a by-product of sulfite pulping.

Embodiment 3

[0034] Parts by mass, g / mL, take 4.90 parts by mass of polyvinyl alcohol and 0.10 parts by mass of lignin, 0.5 parts by mass of 1-(3-aminopropyl) imidazole, add 100 parts by volume of water; under the condition of heating temperature 70°C, 300rpm After mechanical stirring for 5 hours, the fully dissolved mixed solution was cast into a film, and the lignin / polyvinyl alcohol composite material was obtained after the water was naturally volatilized at room temperature. Wherein, the selected polyvinyl alcohol Mw=89000g / mol, the degree of hydrolysis is 99%. The selected lignin is lignosulfonic acid, a by-product of sulfite pulping.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com