Processing method of concrete holes or exposed bars

A treatment method, concrete technology, applied in construction, building maintenance, building construction, etc., can solve the problems of reducing the bond strength between materials, affecting the durability of the structure, and long construction period, so as to improve construction performance and workability , The effect of low drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

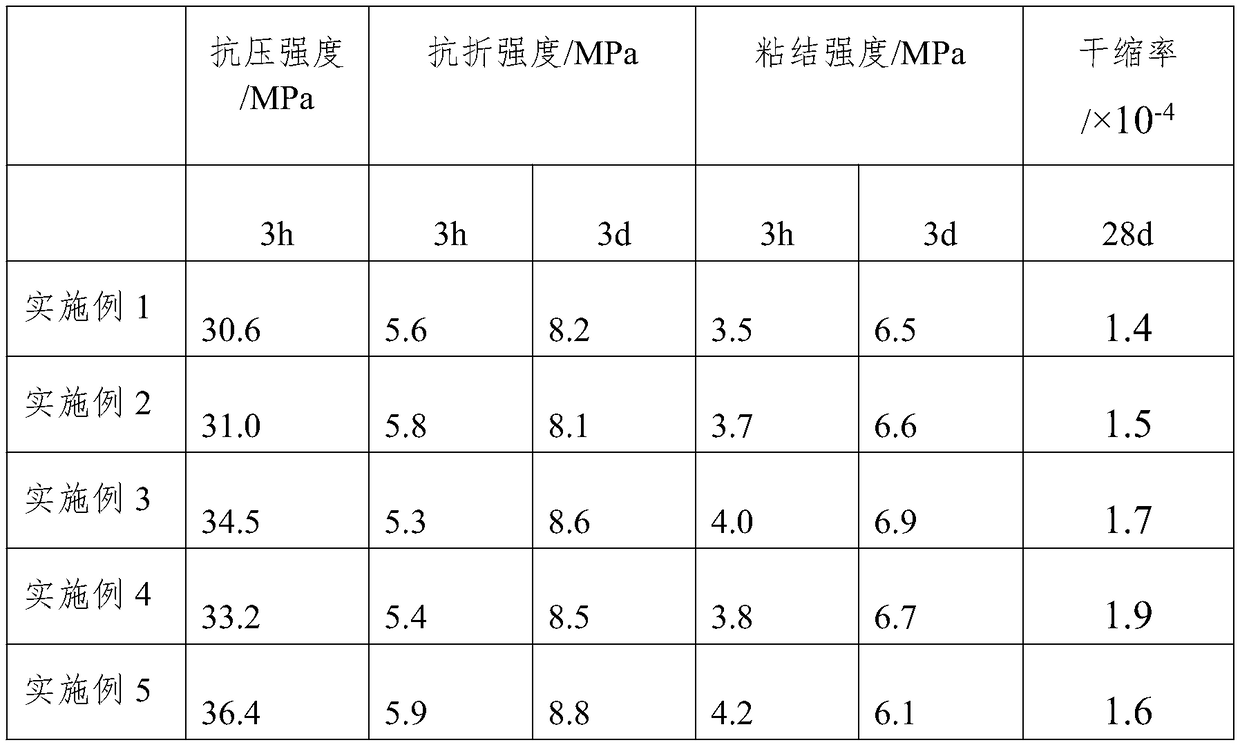

Examples

Embodiment 1

[0030] This embodiment provides a treatment method for concrete holes or exposed bars, the steps comprising:

[0031] S1 Chisel removal of unqualified concrete: Chisel away uncompacted loose concrete and floating stones, check that the surface of the concrete after chiseling is dense and there are no obvious gaps;

[0032] S2 interface cleaning: use high-pressure air to clean the residue in the tank and rinse it with high-pressure water;

[0033] S3 mold support: choose plastic formwork for mold support;

[0034] S4 Stirring: Pour the concrete repair material into the mixing container, add water until the diffusion degree is 450-600mm, and stir evenly;

[0035] S5 pouring of concrete repair material: pouring the concrete repair material obtained in step S4, and vibrating and compacting;

[0036] S6 maintenance: After initial setting, cover with plastic film for moisturizing and curing for 3 hours;

[0037] S7 formwork removal: remove the formwork after maintenance;

[0038...

Embodiment 2

[0044] This embodiment provides a treatment method for concrete holes or exposed bars, the steps comprising:

[0045] S1 Chisel removal of unqualified concrete: Chisel away uncompacted loose concrete and floating stones, check that the surface of the concrete after chiseling is dense and there are no obvious gaps;

[0046]S2 interface cleaning: use high-pressure air to clean the residue in the tank and rinse it with high-pressure water;

[0047] S3 mold support: choose plastic formwork for mold support;

[0048] S4 Stirring: Pour the concrete repair material into the mixing container, add water until the diffusion degree is 450mm, and stir evenly;

[0049] S5 pouring of concrete repair material: pouring the concrete repair material obtained in step S4, and vibrating and compacting;

[0050] S6 maintenance: After initial setting, cover with plastic film for moisturizing and curing for 3 hours;

[0051] S7 formwork removal: remove the formwork after maintenance;

[0052] S8 ...

Embodiment 3

[0058] This embodiment provides a treatment method for concrete holes or exposed bars, the steps comprising:

[0059] S1 Chisel removal of unqualified concrete: Chisel away uncompacted loose concrete and floating stones, check that the surface of the concrete after chiseling is dense and there are no obvious gaps;

[0060] S2 interface cleaning: use high-pressure air to clean the residue in the tank and rinse it with high-pressure water;

[0061] S3 mold support: choose plastic formwork for mold support;

[0062] S4 Stirring: Pour the concrete repair material into the mixing container, add water until the diffusion degree is 500mm, and stir evenly;

[0063] S5 pouring of concrete repair material: pouring the concrete repair material obtained in step S4, and vibrating and compacting;

[0064] S6 maintenance: After initial setting, cover with plastic film for moisturizing and curing for 3 hours;

[0065] S7 formwork removal: remove the formwork after maintenance;

[0066] S8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com