Nano-modified inorganic heat insulation board and preparation process thereof

An inorganic insulation board and nano-modification technology, applied in the field of building materials, can solve problems such as poor thermal performance, small dry-wet deformation, low water absorption, etc., to achieve improved crack resistance integrity, excellent compatibility, and resource conservation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

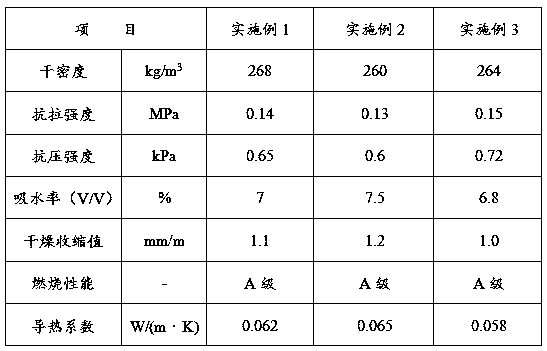

Embodiment 1

[0031] A nano-modified inorganic thermal insulation board, comprising a cement-based lightweight reinforced thermal insulation board core material and a nano-scale polymer emulsion permeable coating, and the cement-based lightweight reinforced thermal insulation board core material is composed of the following raw materials in weight percentage : Portland cement 58%, silica fume 3.1%, fly ash 3.6%, water 30%, aluminate 0.1%, chloride salt 0.33%, stearate water repellent 0.3%, nano-scale graphite 1.5% , modified polypropylene fiber 0.2%, naphthalene dispersant 0.07%, hydrogenated blowing agent 2.8%.

[0032] Wherein, the nano-scale high-molecular polymer emulsion in the nano-scale high-molecular polymer emulsion penetrating coating is a silicone-modified acrylic emulsion, and the penetration depth is 0.8mm.

[0033] The preparation process of the nano-modified inorganic insulation board specifically includes the following steps:

[0034] (1) Pour water, Portland cement, silica...

Embodiment 2

[0037] A nano-modified inorganic thermal insulation board, comprising a cement-based lightweight reinforced thermal insulation board core material and a nano-scale polymer emulsion permeable coating, and the cement-based lightweight reinforced thermal insulation board core material is composed of the following raw materials in weight percentage :

[0038] Ordinary Portland cement 62%, fly ash 4.4%, water 28%, aluminate 0.1%, sulfate 0.45%, stearate water repellent 0.7%, nano-scale graphite 1%, modified polypropylene Fiber 0.3%, polycarboxylate dispersant 0.05%, hydrogenated blowing agent 3%.

[0039] Wherein, the nanoscale high molecular polymer emulsion in the nanoscale high molecular polymer emulsion penetrating coating is a silicone-modified styrene-acrylic emulsion, and the penetration depth is 0.5mm.

[0040] The preparation process of the nano-modified inorganic insulation board specifically includes the following steps:

[0041] (1) Pour water, ordinary Portland cemen...

Embodiment 3

[0044] A nano-modified inorganic thermal insulation board, comprising a cement-based lightweight reinforced thermal insulation board core material and a nano-scale polymer emulsion permeable coating, and the cement-based lightweight reinforced thermal insulation board core material is composed of the following raw materials in weight percentage :

[0045] Portland cement 60%, mineral powder 5%, water 28.84%, triethanolamine 0.03%, aluminate 0.15%, stearate water repellent 0.6%, nano-scale graphite 2%, modified polypropylene fiber 0.4 %, naphthalene-based dispersant 0.08%, hydrogenated blowing agent 2.9%.

[0046] Wherein, the nanoscale high molecular polymer emulsion in the nanoscale high molecular polymer emulsion penetrating coating is a silicone-modified acrylic emulsion, and the penetration depth is 0.7mm.

[0047] The preparation process of the nano-modified inorganic insulation board specifically includes the following steps:

[0048] (1) Pour water, portland cement, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration depth | aaaaa | aaaaa |

| Penetration depth | aaaaa | aaaaa |

| Penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com