Extrusion molding method for high strength double peak polyethylene/chitin nano crystal composite material

A technology of chitin nanocrystals and bimodal polyethylene, which is applied in the field of bimodal polyethylene products, can solve problems such as insufficient mechanical properties of bimodal polyethylene, and achieve the effect of promoting formation and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

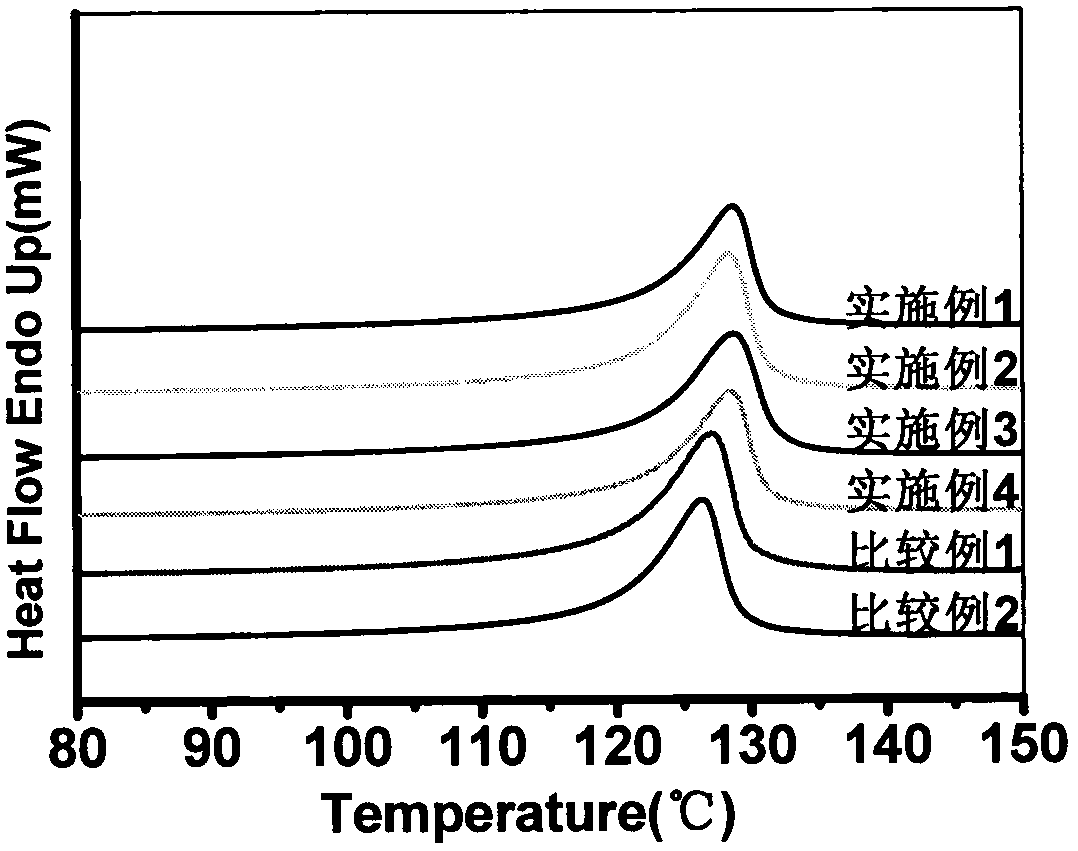

Image

Examples

Embodiment 1

[0036] 1000g of bimodal polyethylene with a weight average molecular weight of 210,000 and a molecular weight distribution of 24, 100mg of chitin nanocrystals with a diameter of 10nm and a length of 200nm, 1250mg of antioxidant 1010, and 1000mg of lubricant were added to the conical twin-screw extruder The bimodal polyethylene / chitin nanocrystalline composite product is obtained by extruding after uniform blending in the machine, wherein the bimodal polyethylene does not contain branched chains, the mass content of the high molecular weight part is 10%, the weight average molecular weight is 820,000, and the molecular weight distribution 3, the mass content of the low molecular weight part of bimodal polyethylene is 90%, the weight average molecular weight is 170000, and the molecular weight distribution is 4; the blending time is 0.5min; the temperature of the feed section of the extruder is 120°C, and the temperature of the compression section is 170°C, the temperature of the...

Embodiment 2

[0038] Add 1000g of bimodal polyethylene with a weight average molecular weight of 350000 and a molecular weight distribution of 35, 5g of chitin nanocrystals with a diameter of 40nm and a length of 1000nm, 800mg of antioxidant 1076, and 600mg of a flame retardant into the parallel and same direction bimodal The screw extruder is uniformly blended and then extruded to obtain a bimodal polyethylene / chitin nanocrystalline composite product, wherein the bimodal polyethylene does not contain branched chains, the mass content of the high molecular weight part is 30%, and the weight average molecular weight is 1,000,000, The molecular weight distribution is 5, the mass content of the low molecular weight part of bimodal polyethylene is 70%, the weight average molecular weight is 60000, and the molecular weight distribution is 5; the blending time is 3min; the feeding section temperature of the extruder is 130°C, the compression section temperature The temperature of the homogenizatio...

Embodiment 3

[0040] Add 1000g of bimodal polyethylene with a weight average molecular weight of 360000 and a molecular weight distribution of 36, 5g of chitin nanocrystals with a diameter of 40nm and a length of 1000nm, 800mg of antioxidant 1076, and 600mg of a flame retardant The screw extruder is uniformly blended and then extruded to obtain a bimodal polyethylene / chitin nanocrystalline composite product, wherein the bimodal polyethylene high molecular weight part has a mass content of 30%, a weight average molecular weight of 1,020,000, and a molecular weight distribution of 5. The high molecular weight part contains 30 ethyl branched chains per 10,000 carbon atoms, the mass content of the bimodal polyethylene low molecular weight part is 70%, the weight average molecular weight is 62000, and the molecular weight distribution is 5; the blending time is 3 minutes; the extruder The temperature of the feed section is 130°C, the temperature of the compression section is 200°C, the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com