Directional casting machine for nonferrous metals

A technology of directional casting and non-ferrous metals, applied in the field of castings, can solve the problems of large torsional yield stress of castings, achieve the effects of improving grain structure, ensuring behavior and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

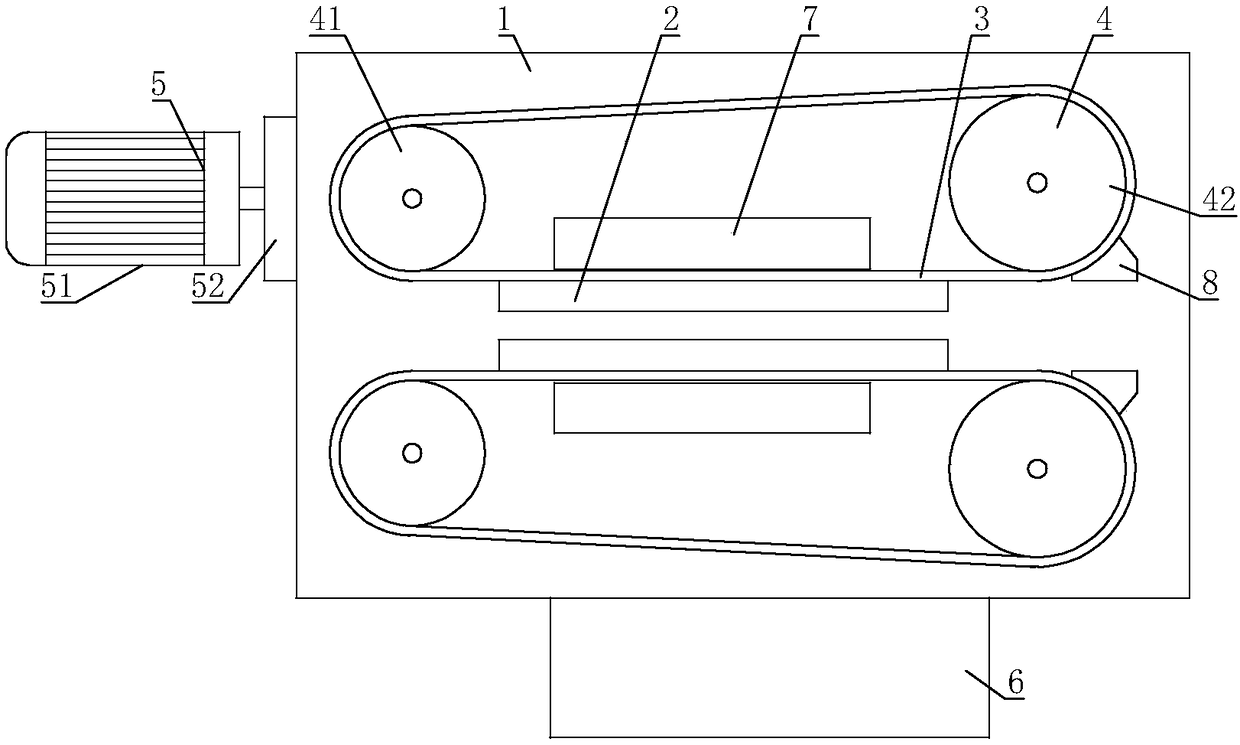

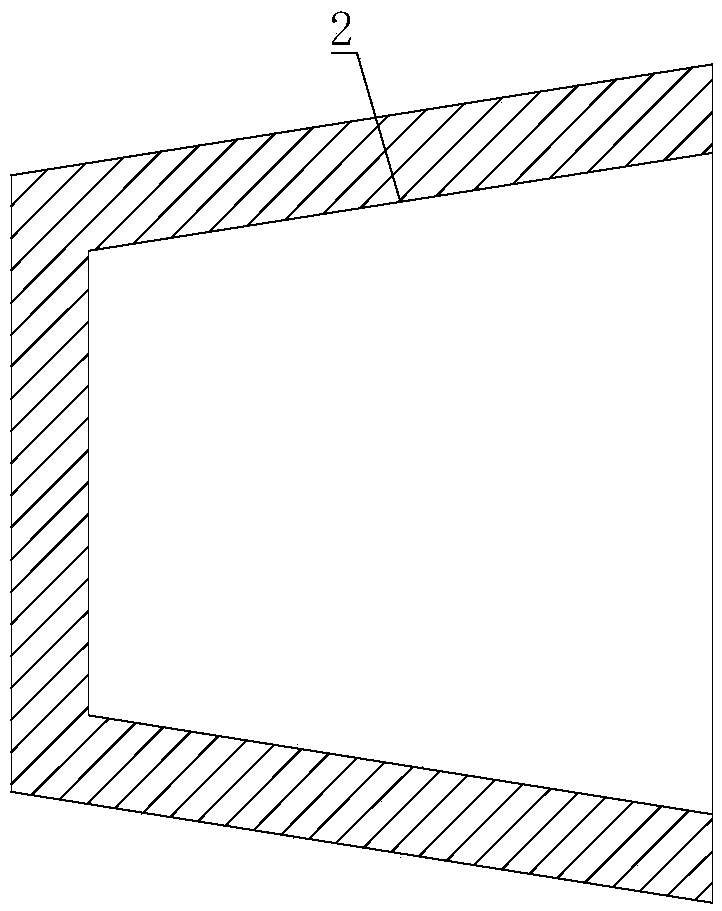

[0025] A non-ferrous metal directional caster, comprising a frame 1, a crystallizer 2 is installed on the frame 1, one side of the crystallizer 2 is open, and a steel strip 3 is assembled on one side of the crystallizer 2 opening, and the steel strip 3 is connected with the crystallizer 2 form a trapezoidal cavity, the shape of the trapezoidal cavity is a trapezoidal column, one end of the trapezoidal cavity is provided with a casting port, the other end of the trapezoidal cavity is provided with a discharge port, and the frame 1 is equipped with a steel belt 3 Continuously moving pulling mechanism 4 , a driving mechanism 5 for driving the pulling mechanism 4 is installed on the frame 1 , and the output shaft of the driving mechanism 5 is connected with the pulling mechanism 4 .

[0026] The driving mechanism 5 of the present invention drives the pulling mechanism 4 to act, and the pulling mechanism 4 can pull the steel belt 3 to move continuously, and then the casting can be c...

Embodiment 2

[0028] On the basis of Embodiment 1, the pulling mechanism 4 includes a driving wheel 41 and a driven wheel 42, the driving wheel 41 and the driven wheel 42 are installed on the frame 1 through bearings, the rotating shaft of the driving wheel 41 and the output shaft of the driving mechanism 5 Connection, the steel belt 3 is connected end to end, and the steel belt 3 is lapped on the driving wheel 41 and the driven wheel 42.

[0029] The driving mechanism 5 can drive the driving wheel 41 to rotate, then the driving wheel 41 drives the steel belt 3 and the driven wheel 42 to move, and the steel belt 3 can continuously take the casting out of the trapezoidal mold cavity. Realized the continuous production of trapezoidal castings.

Embodiment 3

[0031] On the basis of Embodiment 1 or Embodiment 2, the driving mechanism 5 includes a motor 51 , the output shaft of the motor 51 is connected with a reducer 52 , and the output shaft of the reducer 52 is connected with the pulling mechanism 4 .

[0032] After the motor 51 starts, the motor 51 drives the speed reducer 52 to act, and the speed reducer 52 drives the pulling mechanism 4 to move, so the pulling mechanism 4 can pull the steel strip 3 continuously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com