Wet electrostatic precipitator

A wet electrostatic precipitator, working tank technology, applied in the direction of external electrostatic separator, electrode cleaning, electrostatic separation, etc., can solve the problems of liquid waste, increase the frequency of liquid flushing, incomplete dust cleaning, etc., to expand the collection range , Improve the accuracy and improve the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

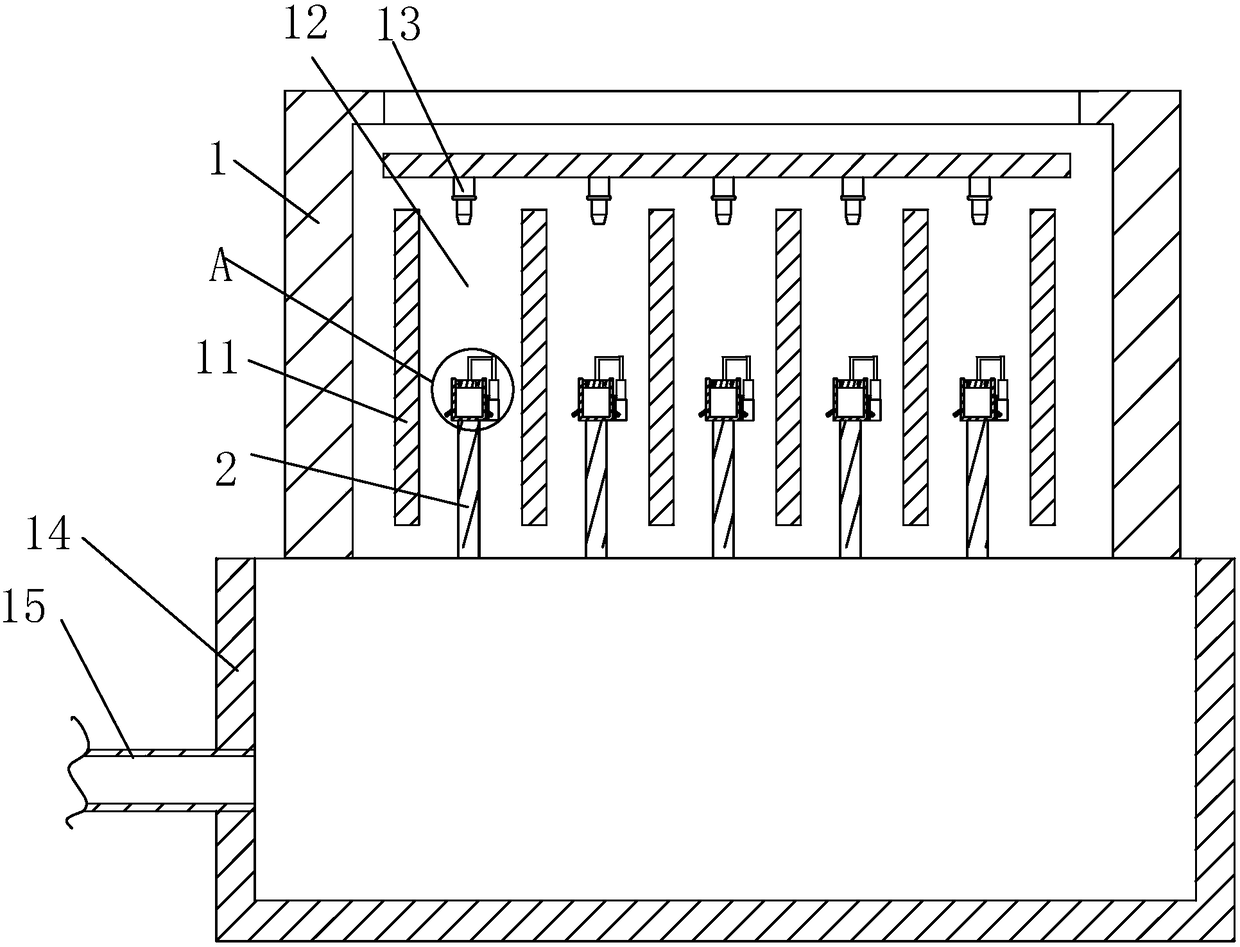

[0040] Embodiment 1: a kind of wet electrostatic precipitator, such as figure 1 As shown, the casing 1 is included, and the inside of the casing 1 is provided with a plurality of integrated boards 11 arranged in a vertical array, and a channel space 12 for gas circulation is provided between every two integrated boards 11, and in each channel A plurality of nozzle devices 13 extending along the length direction of the integrated board 11 are arrayed directly above the space 12, and a water storage tank 14 for storing waste liquid is provided in the housing 1 below the integrated board 11. One of the water storage tanks 14 The side is provided with the water pipe 15 for waste liquid discharge.

[0041]The gas containing dust enters the wet electrostatic precipitator, and the wet electrostatic precipitator charges the dust through high-voltage corona discharge, and the charged dust adheres to the surface of the integrated board 11 to realize the separation of the dust in the gas...

Embodiment 2

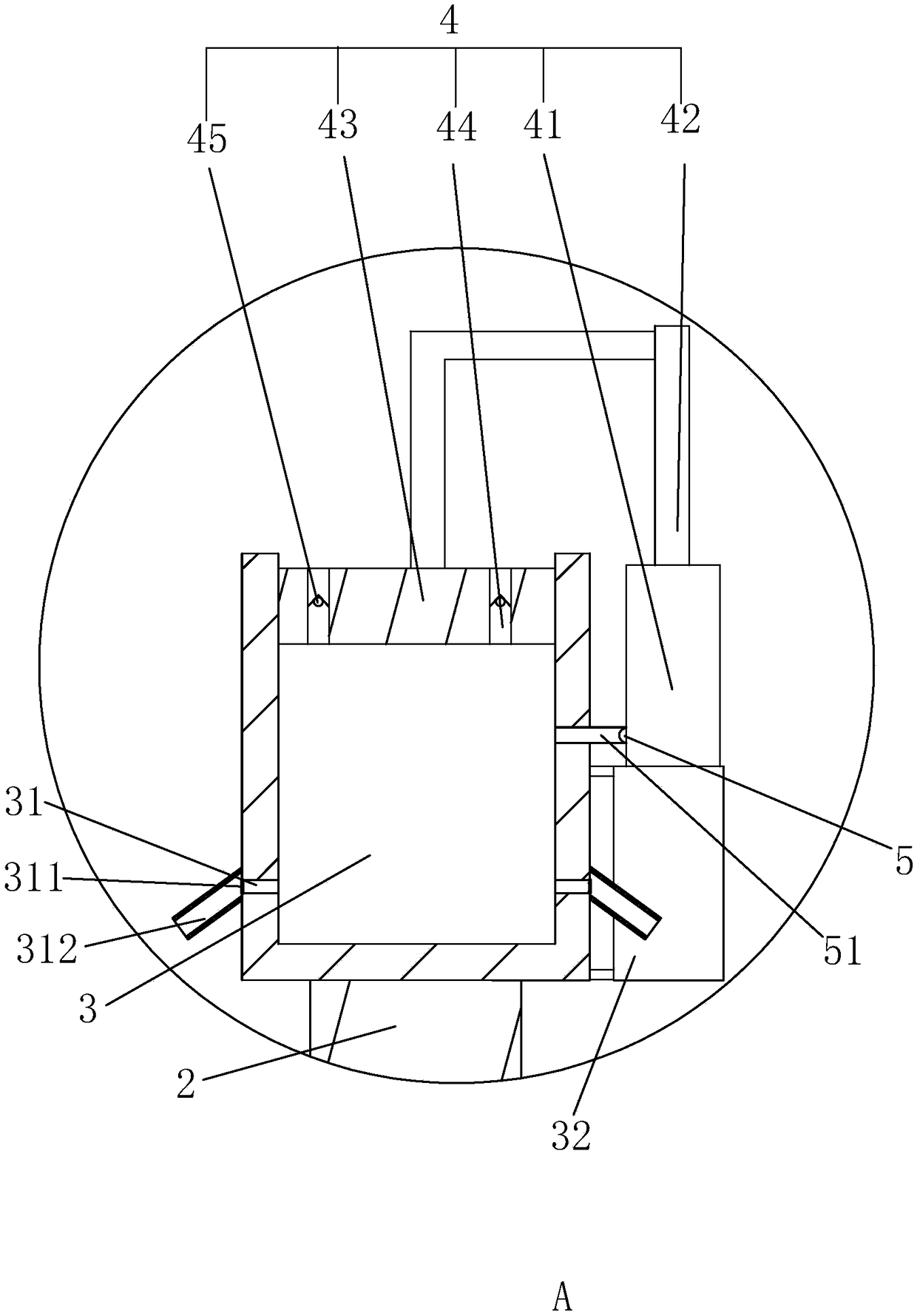

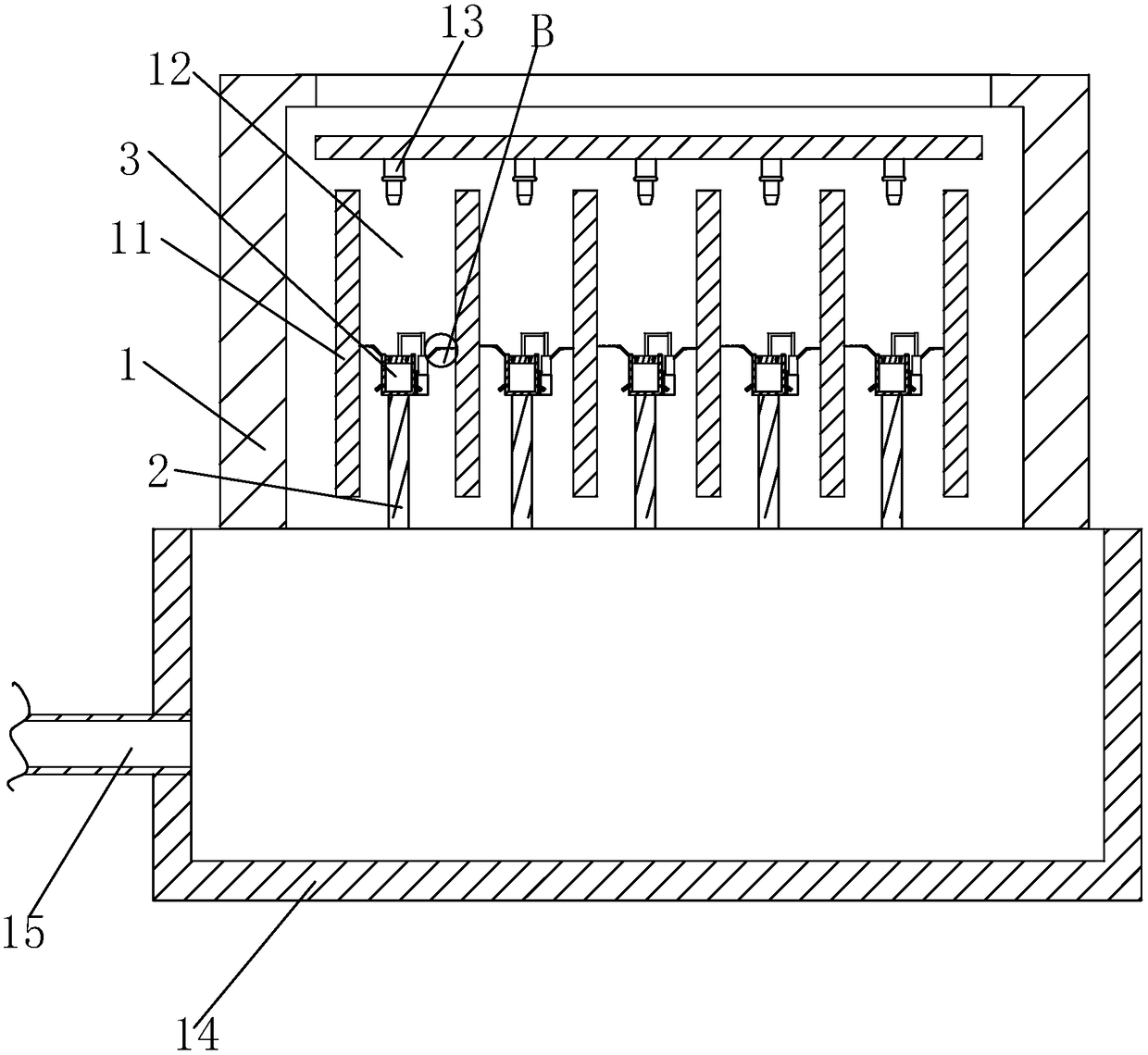

[0047] Embodiment 2: a kind of wet electrostatic precipitator, the difference with embodiment 1 is, as image 3 with 4 As shown, in order to make the working tank 3 better collect the liquid and reduce the waste of liquid, at this time, both sides of the working tank 3 are fixed and inclined with deflectors 33, that is, a deflector 33 is obliquely fixedly arranged on the working tank. On the outer side wall of the groove 3, another deflector 33 is obliquely fixedly arranged on the outer side wall of the driving cylinder 41; There is a notch groove 341 for the liquid to pass through, and a connecting spring 35 is fixed on the bottom of the deflector 33. The end of the connecting spring 35 away from the deflector 33 is connected and fixed to the bottom of the swing plate 34, that is, the connecting spring 35 can realize Supporting effect on the swing plate 34; at the same time, a brush layer 331 is provided on the side of the swing plate 34 away from the deflector 33, and the b...

Embodiment 3

[0051] Embodiment 3: a kind of wet electrostatic precipitator, the difference with embodiment 2 is, as Figure 5 As shown, at this time, a plurality of support springs 21 connected and fixed to the bottom of the working tank 3 are arranged in an array on the support plate 2 .

[0052] Specific implementation method: when there is no liquid in the working tank 3, the supporting springs 21 are not fully compressed, which can realize the supporting effect on the working tank 3, when the liquid is stored in the working tank 3, and under the extrusion effect of the sealing piston 43 , can realize the compression of the supporting spring 21, and the process of compressing the supporting spring 21 realizes the downward movement of the working tank 3. In this process, it can realize the scouring effect on the dust adhered on the integrated board 11 near the lower part, further improving effect on dust removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com