Nanosheet-nanorod coupled three-dimensional composite Ni-Co modified molybdenum carbide electrocatalysis hydrogen production catalyst and preparation method thereof

A technology of composite materials and nanorods, applied in the field of electrocatalytic hydrogen production, to achieve the effects of simple process operation, accelerated transfer rate, and mature and stable synthesis technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

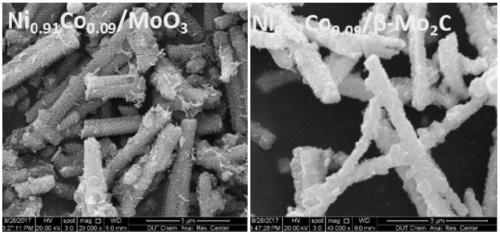

[0032] 1) Preparation of catalyst:

[0033] a) 2.1g ammonium heptamolybdate tetrahydrate ((NH 4 ) 7 Mo 7 o 24 4H 2O, denoted as AM) was dissolved in 60mL nitric acid aqueous solution, wherein the volume ratio of the solution was: 65% concentrated nitric acid / deionized water=1 / 5; after being completely dissolved, the clear solution was transferred to a 100mL polytetrafluoroethylene reaction kettle , sealed and placed in a homogeneous reactor, and reacted at 200°C for 20h. The solid product obtained by filtration was alternately washed several times with deionized water and absolute ethanol until the washing liquid was neutral, and then dried in an oven at 80°C overnight to obtain off-white MoO 3 Nanorod precursors.

[0034] b) Take 930mg nickel acetate (Ni(CH 3 COO) 2 ) and 97.5mg cobalt chloride (CoCl 2 ·6H 2 O) metal salt is dissolved in the mixed solution of 100ml water and ethanol, fully dissolves; Wherein, the volume ratio of water and ethanol is 1:1, then adds t...

Embodiment 2

[0041] Get 1026mg nickel acetate (Ni(CH 3 COO) 2 ) Metal salt is dissolved in the mixed solution of 100ml water and ethanol, fully dissolves; Wherein, the volume ratio of water and ethanol is 1:1, then add the MoO of 100mg 3 The nanorod precursor was ultrasonicated at room temperature for 30 minutes to form a uniformly dispersed suspension. The suspension was placed in a 90°C water bath for 6 hours. After the reaction was completed, it was cooled to room temperature and allowed to stand overnight. After filtering, washing and drying, a solid powder sample was obtained. . Finally, the solid powder is placed in a muffle furnace and calcined at 500°C for 2 hours to obtain the desired Ni / MoO 3 Precursor.

[0042] Prepare Ni / MoO as above 3 As a precursor, carbonization is carried out according to the temperature-programmed reaction process described in the catalyst preparation step b) in Example 1, and the three-dimensional nanocomposite structure Ni / β-Mo 2 C catalyst.

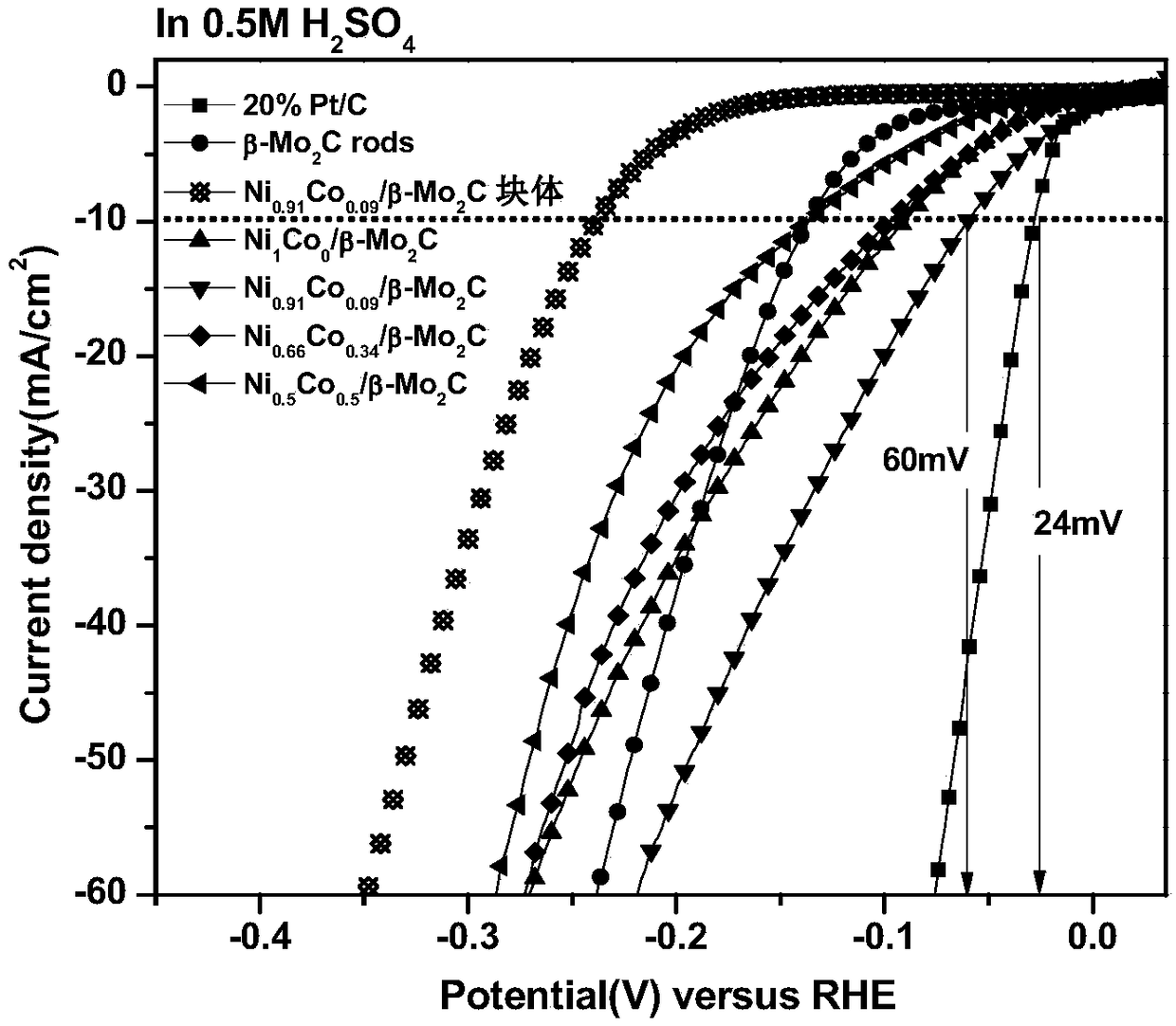

[004...

Embodiment 3

[0046] Get 1146mg nickel acetate (Ni(CH 3 COO) 2 ) and 214mg cobalt chloride (CoCl 2 ·6H 2 O) metal salt is dissolved in the mixed solution of 100ml water and ethanol, fully dissolves; Wherein, the volume ratio of water and ethanol is 1:1, then adds the MoO of 100mg 3 The nanorod precursor was ultrasonicated at room temperature for 30 minutes to form a uniformly dispersed suspension. The suspension was placed in a 90°C water bath for 6 hours. After the reaction was completed, it was cooled to room temperature and allowed to stand overnight. After filtering, washing and drying, a solid powder sample was obtained. . Finally, the solid powder is placed in a muffle furnace and calcined at 500°C for 2 hours to obtain the desired Ni 0.66 co 0.34 / MoO 3 Precursor.

[0047] Ni was prepared as above 0.66 co 0.34 / MoO 3 As a precursor, carbonization is carried out according to the temperature-programmed reaction process described in the catalyst preparation step b) in Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com