A pbat/modified starch fully biodegradable film with both high ductility and high barrier properties and its preparation method and application

A technology of degradable film and ductility, applied in the field of modified starch, can solve the problems of difficult packaging products application, poor barrier performance of PBAT, etc., and achieve the effects of easy operation control, increased extrusion plasticization effect, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

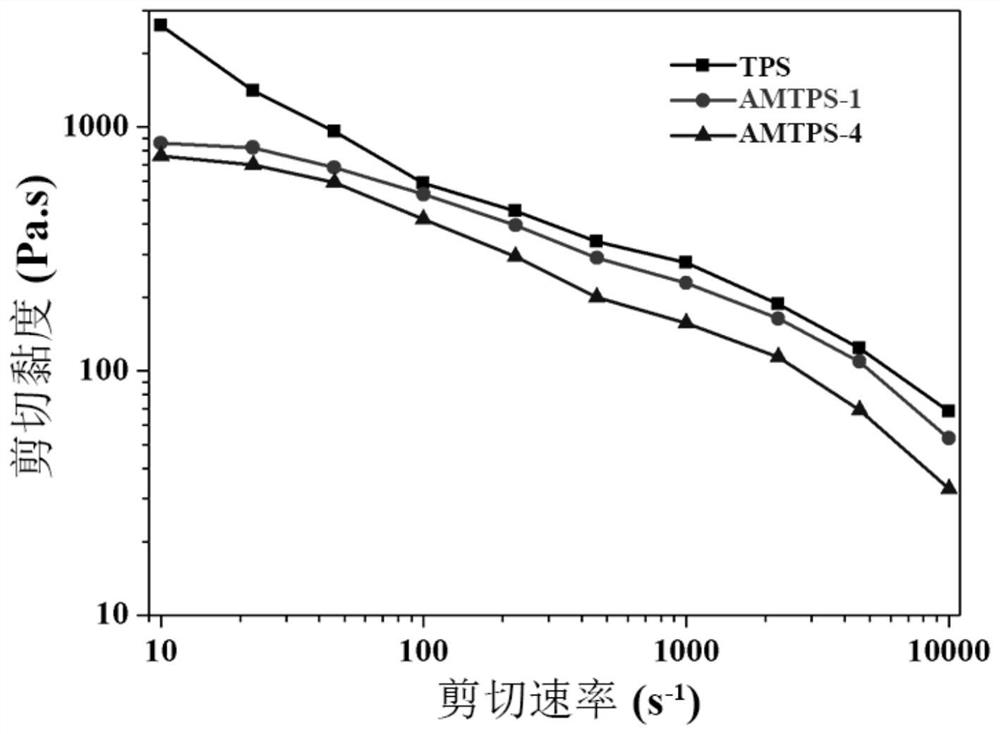

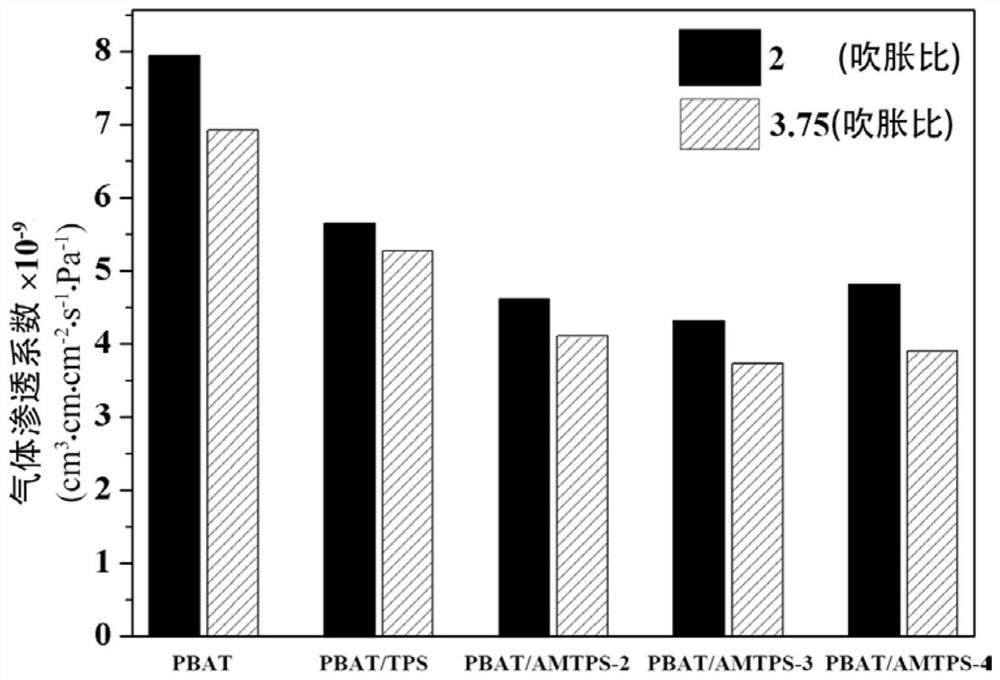

Embodiment 1

[0036] The starch was dried at 110°C for 4h. Then starch and glycerol are pre-mixed according to the mass ratio of 7:3. Then 1% (based on starch quality) tartaric acid is crushed in a high-speed crusher, mixed with starch / glycerol premixture, and extruded by twin-screw reaction (extrusion temperature 125-145°C, screw speed 80 rpm) , granulated to obtain acidified modified thermoplastic starch (AMTPS-1).

Embodiment 2

[0038]The starch was dried at 110°C for 4h. Then starch and glycerol are pre-mixed according to the mass ratio of 8:2. Then 2% (based on starch quality) tartaric acid is crushed in a high-speed crusher, mixed with starch / glycerol premixture, and extruded by twin-screw reaction (extrusion temperature 125-145°C, screw speed 80 rpm) , granulated to obtain acidified modified thermoplastic starch (AMTPS-2).

Embodiment 3

[0040] The starch was dried at 110°C for 4h. Then starch and glycerol are pre-mixed according to the mass ratio of 7:3. Then 3% (based on starch quality) tartaric acid is crushed in a high-speed crusher, mixed with starch / glycerol premixture, and extruded by twin-screw reaction (extrusion temperature 125-145 ° C, screw speed is 80 rpm) , granulated to obtain acidified modified thermoplastic starch (AMTPS-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com