Arc-aligning device and an arc-aligning method used between crystallizer and bending section of continuous casting machine

A crystallizer and bending section technology, applied in the field of straight and curved continuous casting machines, can solve problems such as poor safety, high risk, and arc alignment errors, and achieve the effects of improving equipment precision, high labor efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

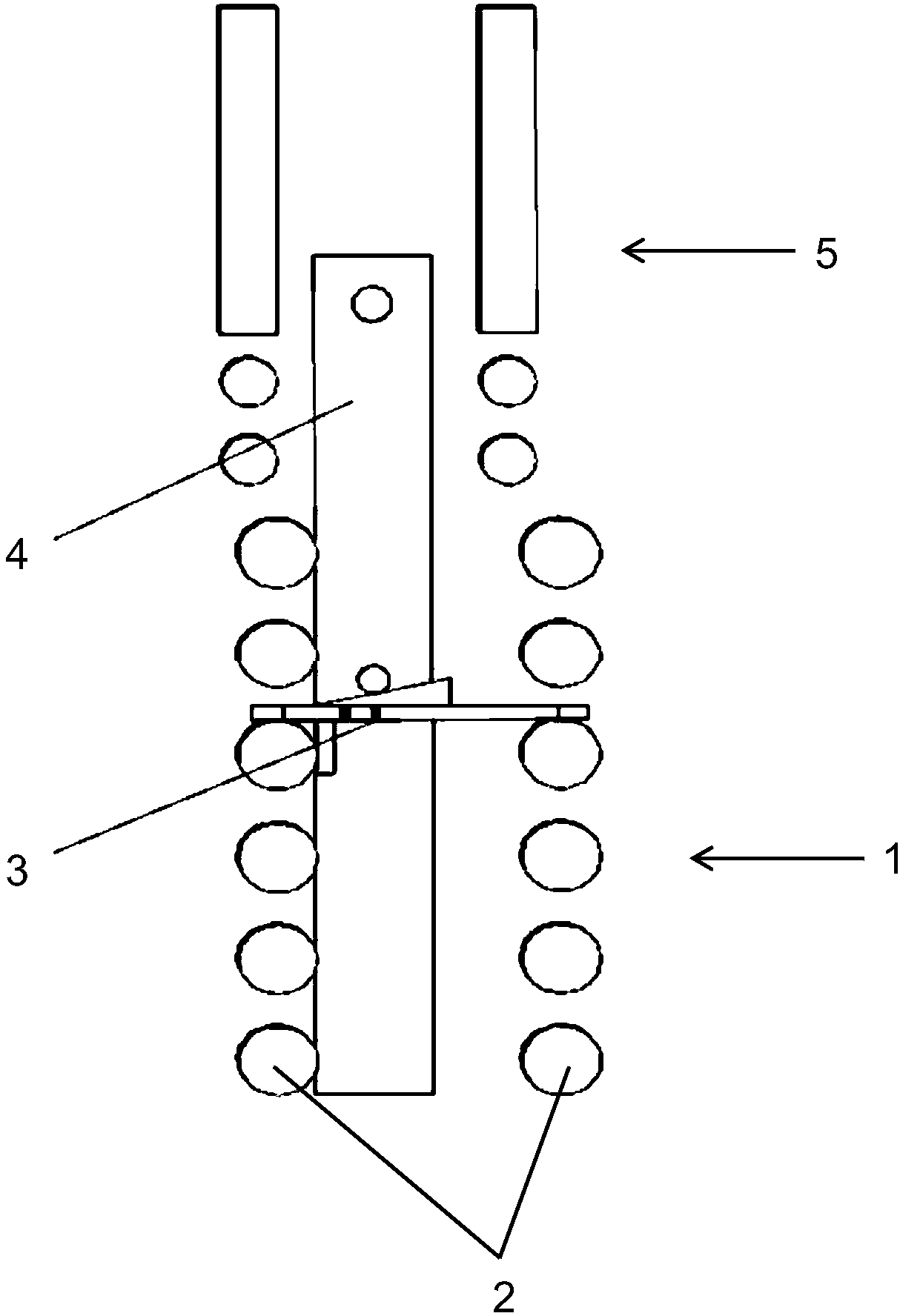

[0030] Please combine Figure 1 to Figure 3 As shown, the arc alignment device between the crystallizer and the bending section of the continuous casting machine provided by the present invention includes several pairs of rollers 2 arranged on both sides of the bending section 1, and also includes an arc alignment support 3 and an arc alignment plate 4.

[0031] Preferably, the arc-aligning support 3 is arranged between the rollers 2 on both sides of the bending section 1, and includes a bottom plate 301, a bevel 302 and a bottom plate positioning support plate 303. The bottom plate 301 is arranged in a rectangular shape, and in the longitudinal direction of the bottom plate 301 At the center position of the arc plate 4, a guide positioning groove 304 is cut out for the passage of the arc plate 4. The length of the guide posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com