Cement scale cleaning device for cement production and cleaning method thereof

A cleaning device and technology for cleaning devices, which are applied in cleaning methods and utensils, chemical instruments and methods, and smoke and dust removal, etc., can solve problems such as low cleaning efficiency, and achieve the effect of improving removal effect and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

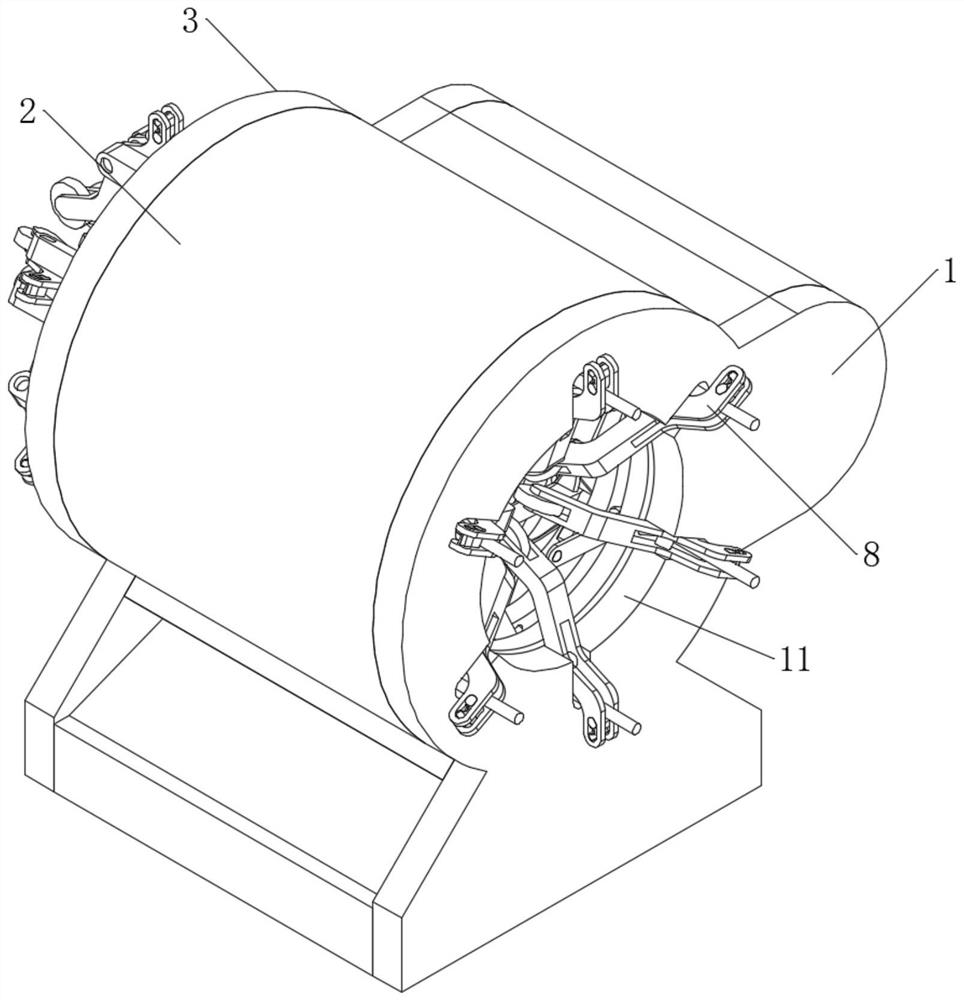

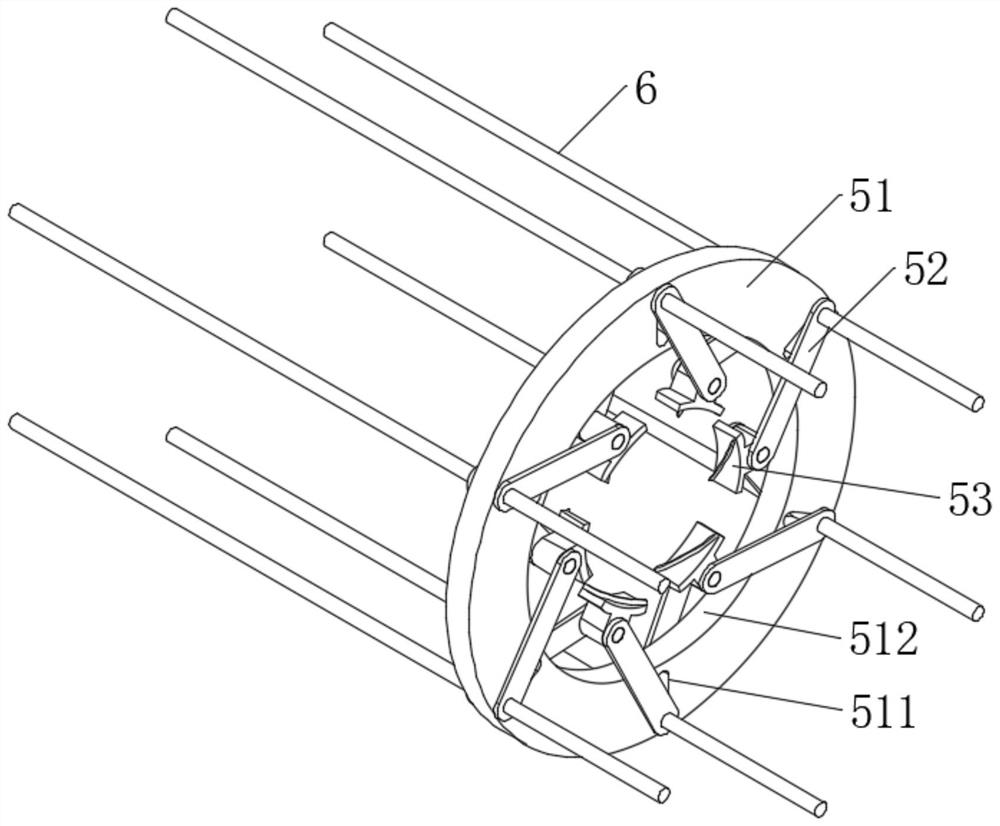

[0037] Such as Figure 1-6 As shown, the present invention is a cement fouling cleaning device for cement production, comprising a shell 2 with two openings, an end cover 1 is installed on one opening of the shell 2, and an end cover 1 is installed on the other opening of the shell 2. The end cover 2 3 is fitted together, the end cover 1 and the end cover 2 3 are provided with a light hole 11, the end cover 1 and the end cover 2 3 are equipped with a limiter 8 pointing to the axis of the light hole 11, and the shell Body 2 comprises a columnar housing one 21 and a columnar housing two 22, a cleaning device is installed for rotation in the cylindrical housing one 21, a power mechanism 7 is installed in the columnar housing two 22, and the power mechanism 7 drives the cleaning device to rotate, wherein the housing Body 2 also comprises inclined plate 23 and seat body 25, and the bottom of columnar housing one 21 is provided with notch, and notch place extends downwards to have s...

Embodiment 2

[0052] Such as Figure 7 Shown, the present invention is a kind of cleaning method of the cement fouling cleaning device that cement production is used, comprises the following steps:

[0053] Step 1, turn on the power supply, the motor 74 drives the transmission shaft 71 provided with the belt 73 to rotate, and the gear 72 fixedly installed on the transmission shaft 71 drives the transmission disc 4 to rotate at the same time, and the transmission disc 4 provided passes through several rotating discs The rod body 6 of 5 drives the rotating disc 5 to rotate;

[0054] Step 2, put in the metal rod body, the metal steel pipe extends into the interior of the housing 2 through the light hole 11 provided on the end cover 1, and the metal steel pipe pushes the end with the roller 83 installed in the limit part 8 during the extension process. The part rotates to the outside, and the pin body 84 pushes the provided rod body 6 to move along the bar-shaped hole-41 to the axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com