Single row interval conveying method of water-feeding monomer material

A material and monomer technology, applied in the field of monomer material classification, can solve the problems of monomer material disintegration, weak coupling force, etc., and achieve the effect of enhancing the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

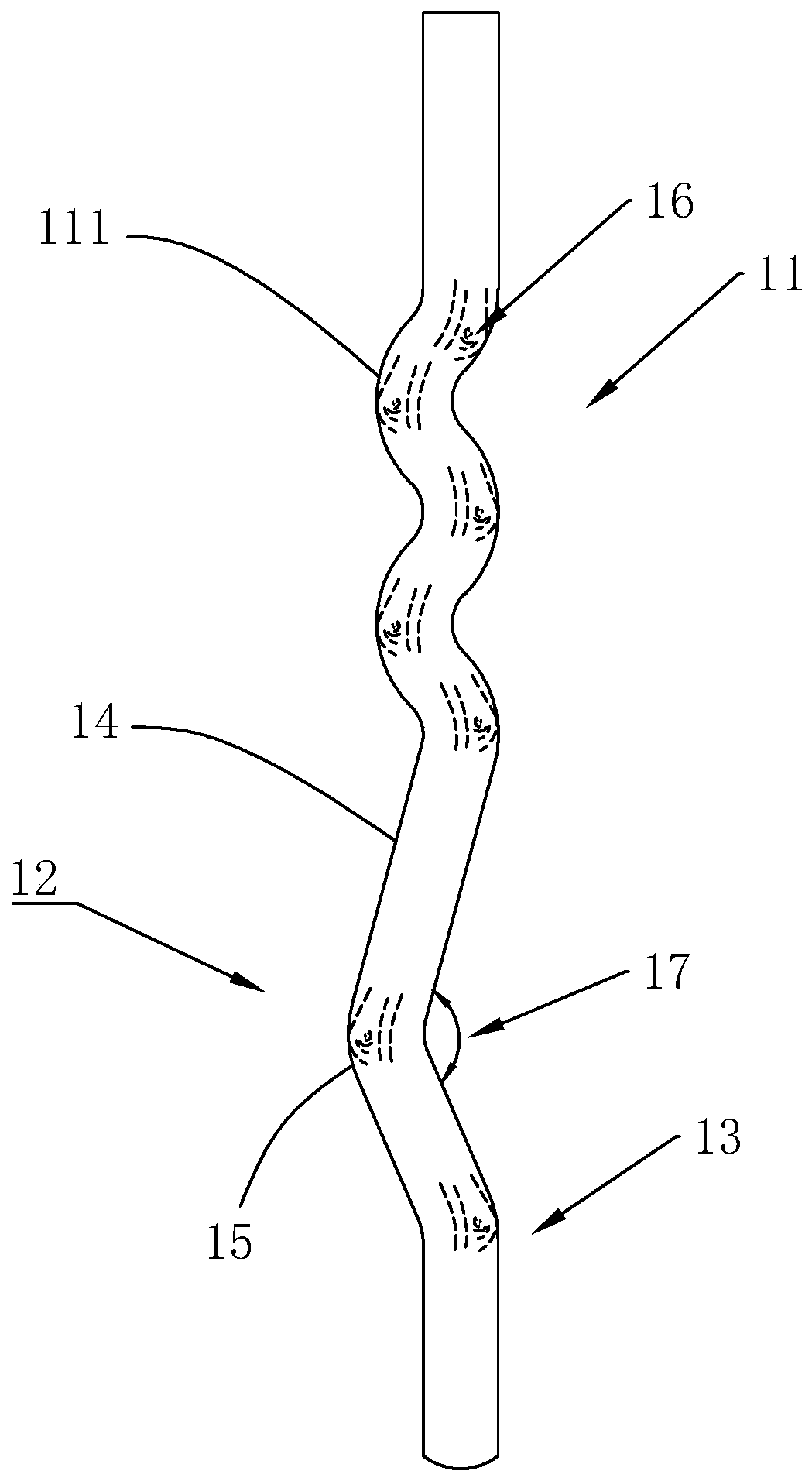

[0048] The difference between this embodiment and Embodiment 1 is that: Figure 4 As shown, the primary deflection section 11 includes three arc-shaped deflection grooves 111 , thereby forming three turbulent flow deflection points 16 .

Embodiment 3

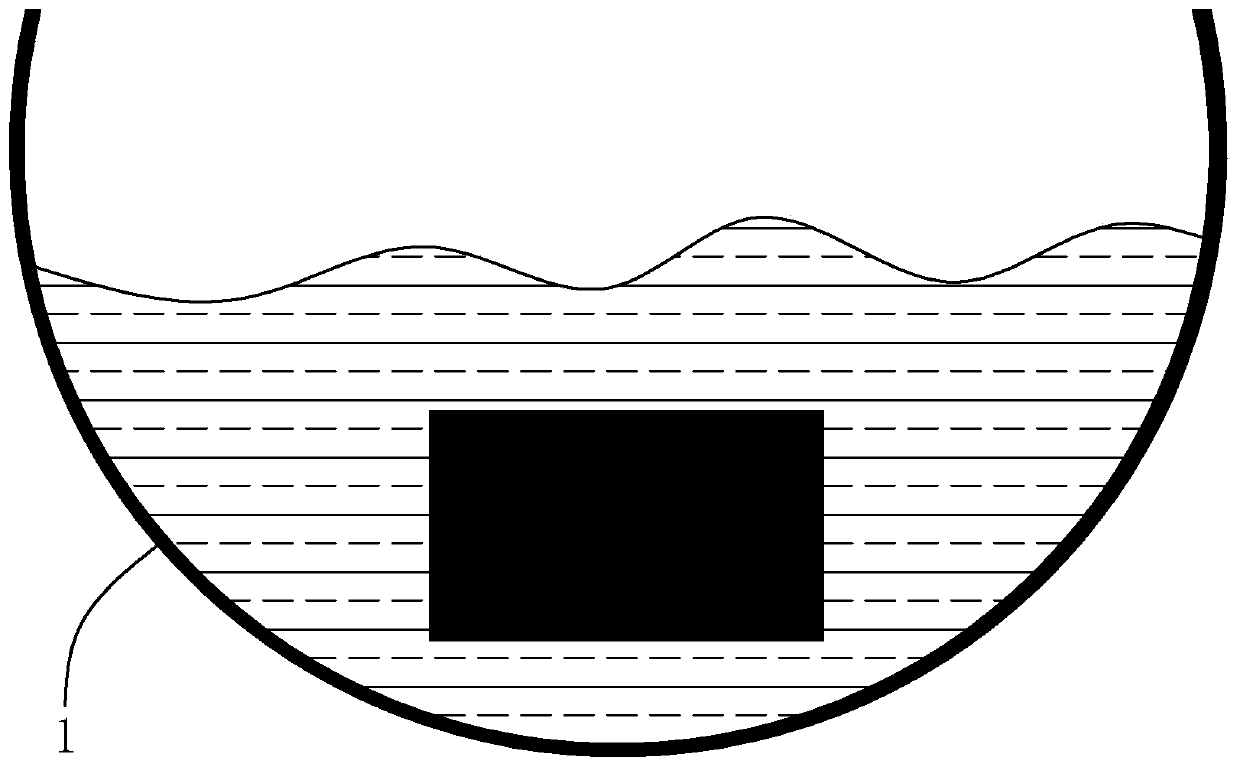

[0050] The difference between this embodiment and Embodiment 1 is that: Figure 5 As shown, the material sorting trough 1 includes a plurality of bending sections sequentially from the feed inlet to the discharge outlet, and a straight line stabilizing section 14 is arranged between adjacent bending sections, and the bending sections are preferably both ends and The delivery groove of the adjacent linear steady flow section 14 is tangent to the arc turning groove 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com