Water-saving environment-friendly cooling tower

A cooling tower and environment-friendly technology, applied in the field of cooling towers, can solve the problems of inconvenient operation, manual adjustment, inability to achieve cooling of high-temperature gas, etc., and achieve the effect of convenient adjustment and saving cooling water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

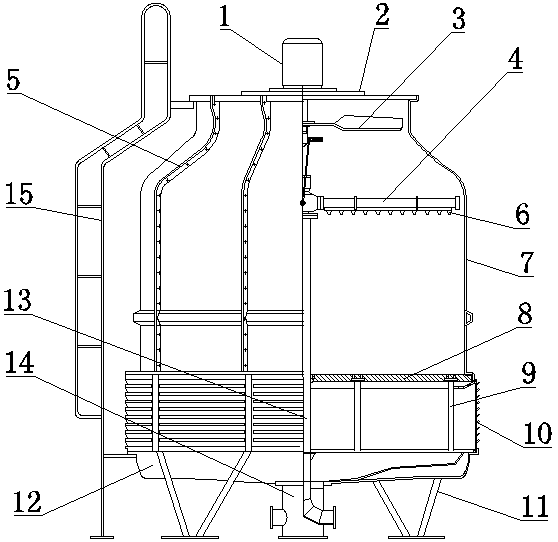

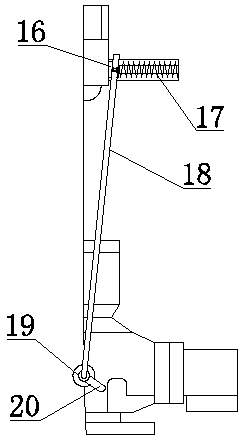

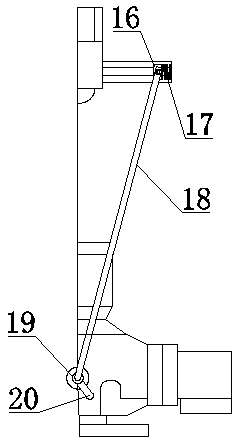

[0025] In Embodiment 1, a water-saving and environmentally friendly cooling tower includes an upper tower body 7 and a lower tower body 12, and is characterized in that: the upper tower body 7 has an upper end opening, and a fan support 2 is installed at the position of the upper end opening. , a motor reducer 1 is installed on the fan support 2, the lower end of the motor reducer 1 is installed with symmetrically distributed fan blades 3, and a spray system is installed in the middle position of the upper tower body 7, The spray system includes a water inlet pipe 13, a spray pipe 4 connected to the water inlet pipe 13, and a nozzle 6 installed on the spray pipe 4. There is also a gap between the rotating shaft at the lower end of the motor reducer 1 and the water inlet pipe 13. An adjustment device for controlling the amount of spray water is provided. The adjustment device includes a moving slider 16 installed at the lower end of the motor reducer shaft. The moving slider 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com