Anti-stripping water quantity distribution method for hot continuous rolling machine

An anti-stripping water and water distribution technology, applied in metal rolling, metal rolling, computer-aided design, etc., can solve the problems of insufficient anti-stripping ability, high temperature, and peeling of oxide film, so as to improve the anti-stripping ability and oxidation resistance. The effect of reducing the problem of film peeling and reducing the waste of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Anti-stripping water volume distribution of F1-4 of 1780 production line

[0031] Taking the F1-4 unit of the 1780 rolling line as an example, the total water volume of the anti-stripping water is 250l / min, and the upper and lower headers are each 125l / min. The water distribution method is as follows:

[0032] 1) According to the existing product outline, the minimum, average and maximum rolling widths are 900mm, 1300mm and 1630mm respectively;

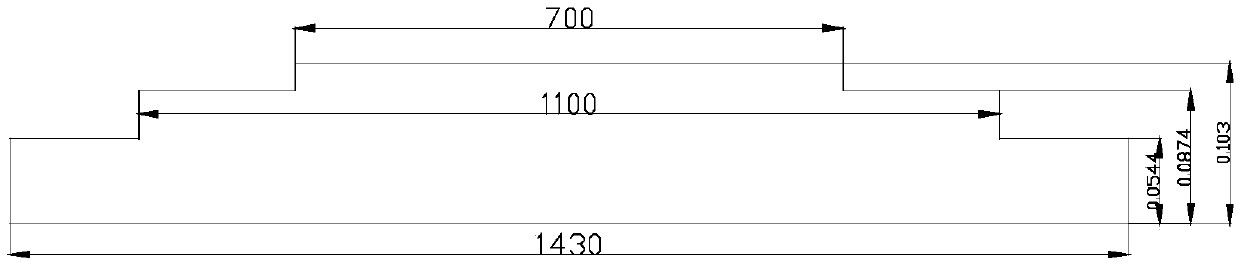

[0033] 2) Determine the cooling width of the strengthened anti-stripping section b1=a1-f, f is the width of the cooling zone at the edge of the strip, and f is 200mm; at this time b1=a1-f=900-200=700 (mm);

[0034] 3) Determine the average cooling width of the anti-stripping section b2=a2-f=1300-200=1100 (mm) (including b1);

[0035] 4) Determine the width of the cooling area of the weakened anti-stripping section b3=a3-f=1630-200=1430 (mm) (including b2);

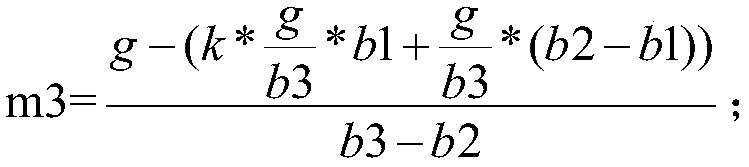

[0036] 5) Determine the average amount of cooling wate...

Embodiment 2

[0045] Example 2: 1422 production line F0-3 anti-stripping water distribution;

[0046] Taking the F1 unit of the 1422 rolling line as an example, the total water volume of F0-3 roll cooling water is 200l / min, and the upper and lower headers are 100l / min each. The water distribution method is as follows:

[0047] 1. According to the existing product outline, the minimum, average and maximum rolling widths are 700mm, 1050mm and 1270mm respectively;

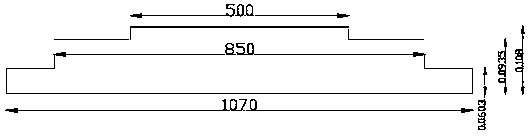

[0048] 2. Determine the cooling width of the strengthened anti-stripping section b1=a1-f, f is the width of the cooling zone at the edge of the strip, and f is 200mm; at this time b1=a1-f=700-200=500 (mm);

[0049] 3. Determine the average cooling width of the anti-stripping section b2=a2-f=1050-200=850 (mm) (including b1);

[0050] 4. Determine the width of the cooling area of the weakened anti-stripping section b3=a3-f=1270-200=1070 (mm) (including b2);

[0051] 5. The average amount of cooling water in the anti-stripping se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com