Method for preparing semi-water gas with fixed bed

A semi-water gas, fixed bed technology, which is applied in the production of combustible gas, combustible gas purification, climate sustainability, etc., can solve the problems of low sensible heat of semi-water gas and low recovery rate of phase change heat, and achieve the effect of reducing the amount of cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

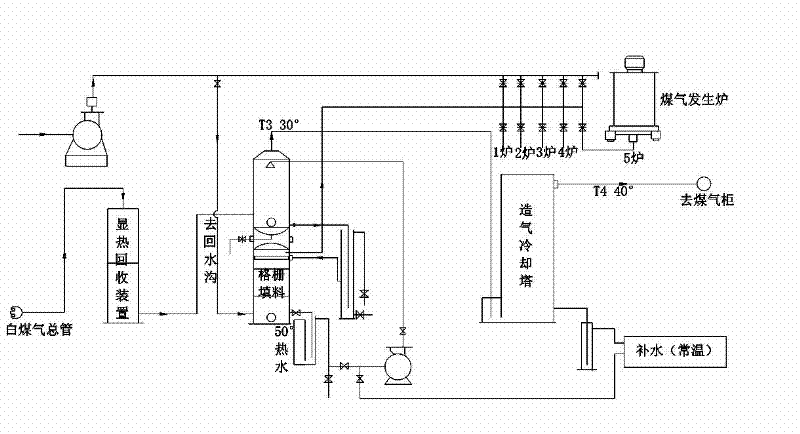

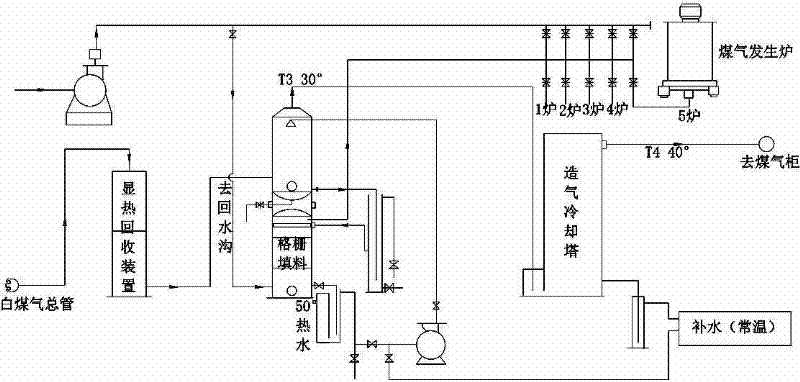

[0018] like figure 1 Shown, a kind of method for fixed-bed system semi-water gas, comprises the following steps:

[0019] a. The semi-water gas at about 250°C from the gas main pipe (introduced from the outlet of the gas generator) first passes through the known sensible heat recovery device to recover part of the sensible heat in the semi-water gas, reducing the gas to 140-170°C;

[0020] b. Semi-water gas at 140-170°C enters the upper tower of the stripping tower. The stripping tower is divided into two parts, the upper tower and the lower tower, and two heads are used in the middle to separate the upper and lower towers. A hot water circulation pump is installed outside the stripping tower to pump the hot water at about 50°C to the top of the upper tower and spray it downwards, and make countercurrent contact with the semi-water gas at 140-170°C inside the stripping tower to recover the water vapor in the semi-water gas The phase change heat of the gas and the sensible he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com