Gradient utilization method for heat energy of polycrystalline silicon production system

A production system, polysilicon technology, applied in control systems, chemical instruments and methods, silicon compounds, etc., can solve problems such as increased steam energy consumption in the system, reduce steam energy consumption, meet equipment energy consumption requirements, and save steam energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is a method for stepwise utilization of thermal energy in a polysilicon production system.

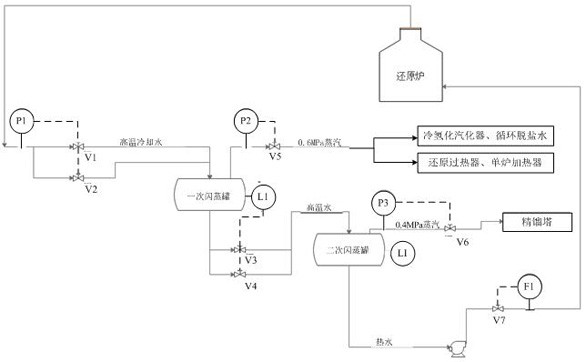

[0028] like figure 1 As shown in the figure, during the operation, the high-temperature cooling water produced by the reduction furnace is flashed through the pressure reducing valve, and the temperature in the primary flash tank is controlled to be 171°C to obtain 0.6MPa steam and 173°C high-temperature water. The water continues to pass through the pressure reducing valve for secondary flash evaporation, and the temperature in the secondary flash evaporation tank is controlled to be 155 °C to obtain 0.4 MPa steam and 153 °C hot water, and the hot water is sent to the reduction furnace for continuous recycling. In order to achieve system pressure balance, the pressure of the reduction furnace should be controlled at 0.5MPa.

[0029] In the above-mentioned cascade flashing process, 0.6MPa steam and 0.4MPa steam are obtained respectively. Among them, the 0.6MPa s...

Embodiment 2

[0032] This embodiment is a method for stepwise utilization of thermal energy in a polysilicon production system.

[0033] like figure 1 As shown in the figure, during the operation, the high-temperature cooling water produced by the reduction furnace is flashed through the pressure reducing valve, and the temperature in the primary flash tank is controlled to be 164°C to obtain 0.6MPa steam and 173°C high-temperature water. The water continues to pass through the pressure reducing valve for secondary flash evaporation, and the temperature in the secondary flash tank is controlled to be 150 °C to obtain 0.4 MPa steam and 153 °C hot water, and the hot water is sent to the reduction furnace for continuous recycling. In order to achieve system pressure balance, the pressure of the reduction furnace should be controlled at 0.51MPa.

[0034] In the above-mentioned cascade flashing process, 0.6MPa steam and 0.4MPa steam are obtained respectively. Among them, 0.6MPa steam can be used ...

Embodiment 3

[0037] This embodiment is a method for stepwise utilization of thermal energy in a polysilicon production system.

[0038] like figure 1 As shown in the figure, during the operation, the high-temperature cooling water produced by the reduction furnace is flashed once through the pressure reducing valve, and the temperature in the primary flash tank is controlled to be 165 °C to obtain 0.6 MPa steam and 174 °C high-temperature water. The water continues to pass through the pressure reducing valve for secondary flash evaporation, and the temperature in the secondary flash tank is controlled to be 151 °C to obtain 0.4 MPa steam and 152 °C hot water, and the hot water is sent to the reduction furnace for continuous recycling. In order to achieve system pressure balance, the pressure of the reduction furnace should be controlled at 0.5MPa.

[0039] In the above-mentioned cascade flashing process, 0.6MPa steam and 0.4MPa steam are obtained respectively. Among them, 0.6MPa steam can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com