Cement pavement EAP fine anti-sliding wear layer and construction method thereof

A cement pavement and construction method technology, applied to roads, roads, on-site coagulation pavement, etc., can solve the problems of limited cement pavement adhesion, easy aging, peeling, etc., to improve anti-skid ability and reduce maintenance Excellent cost and overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

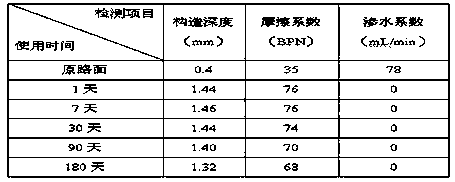

Examples

Embodiment 1

[0029] A cement pavement EAP fine anti-skid wear layer and its construction method are characterized in that it consists of the following components in weight percentage: 100 parts of fine aggregate, 10 parts of epoxy asphalt binder, and 10 parts of stabilizer.

[0030] The particle size of the fine aggregate is 3-5mm, and the refined basalt aggregate (produced in Emei, Sichuan) has a needle flake rate of no more than 5%.

[0031] The stabilizer is epoxy asphalt binder produced by Chongqing Luidas Technology Co., Ltd.

[0032] The epoxy asphalt binder is a four-component liquid epoxy-modified asphalt material with an epoxy resin content of 30% by weight, produced by Chongqing Luidas Technology Co., Ltd.

[0033] The construction method of the EAP fine anti-skid wear layer on the cement pavement comprises the following steps:

[0034] a. Close the construction section, polish the old cement pavement, repair local diseases and clean the road surface;

[0035] b. Prepare variou...

Embodiment 2

[0038] A cement pavement EAP fine anti-skid wear layer and its construction method are characterized in that it consists of the following components in weight percentage: 100 parts of fine aggregate, 15 parts of epoxy asphalt binder, and 8 parts of stabilizer.

[0039] The particle size of the fine aggregate is 3-5mm, and the refined basalt aggregate (produced in Emei, Sichuan) has a needle flake rate of no more than 5%.

[0040] The epoxy asphalt binder is a four-component liquid epoxy-modified asphalt material with an epoxy resin content of 40% by weight, produced by Chongqing Luidas Technology Co., Ltd.

[0041] The stabilizer is modified emulsified asphalt, produced by Chongqing Luidas Technology Co., Ltd.

[0042] The oil-water ratio of the modified emulsified asphalt is 58%, and the softening point of the evaporation residue is 59°C. It is produced by Chongqing Luidas Technology Co., Ltd.

[0043] The construction method of the EAP fine anti-skid wear layer on the cemen...

Embodiment 3

[0048] A cement pavement EAP fine anti-skid wear layer and its construction method are characterized in that it consists of the following components in weight percentage: 100 parts of fine aggregate, 20 parts of epoxy asphalt binder, and 6 parts of stabilizer.

[0049] The particle size of the fine aggregate is 5-8 mm, and the refined basalt aggregate (produced in Emei, Sichuan) has a needle flake rate of not more than 5%.

[0050] The epoxy asphalt binder is a four-component liquid epoxy-modified asphalt material with an epoxy resin content of 50% by weight, produced by Chongqing Luidas Technology Co., Ltd.

[0051] The stabilizer is modified emulsified asphalt, produced by Chongqing Luidas Technology Co., Ltd.

[0052] The oil-water ratio of the modified emulsified asphalt is 60%, and the softening point of the evaporation residue is 60°C. It is produced by Chongqing Luidas Technology Co., Ltd.

[0053] The construction method of the EAP fine anti-skid wear layer on the cem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com