Preparation method of antistatic knitted fabric

A knitted fabric, antistatic technology, applied in conductive/antistatic filament manufacturing, knitting, weft knitting, etc., can solve problems such as loss of function, fabric intolerant to friction, etc., to improve rubbing fastness, durable antistatic performance , excellent wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

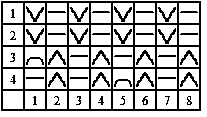

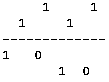

Embodiment 1

[0016] Embodiment 1, a preparation method of an antistatic knitted fabric, including the following steps, step A: adding a conductive substance in the form of a color masterbatch to a conventional synthetic fiber polymer to form a composite conductive fiber. Step B: Select polyester and composite conductive fiber blending as the bottom yarn raw material, select polyester as the surface yarn raw material, and then use the knitting machine to weave the surface yarn and bottom yarn into fabric fabric. In the 8-way triangular structure, the first, third, and fifth , The 7th road is the surface yarn, the 1st road is the loop forming, looping, tucking, floating thread weaving structure cycle, the 3rd road is the looping, looping, floating thread, floating thread weaving structure cycle, the 5th road is forming Loop, loop, float, tuck weaving structure cycle, the 7th road is loop, loop, float, float weaving structure cycle, the 2nd, 4th, 6th, 8th road is the bottom yarn, the 2nd, 4th ...

Embodiment 2

[0017] Embodiment 2, a preparation method of an antistatic knitted fabric, including the following steps, step A: adding a conductive substance in the form of a color masterbatch to a conventional synthetic fiber polymer to form a composite conductive fiber. Step B: Select polyester and composite conductive fiber blending as the bottom yarn raw material, select polyester as the surface yarn raw material, and then use the knitting machine to weave the surface yarn and bottom yarn into fabric fabric. In the 8-way triangular structure, the first, third, and fifth , The 7th road is the surface yarn, the 1st road is the loop forming, looping, tucking, floating thread weaving structure cycle, the 3rd road is the looping, looping, floating thread, floating thread weaving structure cycle, the 5th road is forming Loop, loop, float, tuck weaving structure cycle, the 7th road is loop, loop, float, float weaving structure cycle, the 2nd, 4th, 6th, 8th road is the bottom yarn, the 2nd, 4th ...

Embodiment 3

[0018]Example 3, a method for preparing antistatic knitted fabrics, including the following steps, step A: adding a conductive material in the form of a color masterbatch to a conventional synthetic fiber polymer to form a composite conductive fiber. Step B: Select polyester and composite conductive fiber blending as the bottom yarn raw material, select polyester as the surface yarn raw material, and then use the knitting machine to weave the surface yarn and bottom yarn into fabric fabric. In the 8-way triangular structure, the first, third, and fifth , The 7th road is the surface yarn, the 1st road is the loop forming, looping, tucking, floating thread weaving structure cycle, the 3rd road is the looping, looping, floating thread, floating thread weaving structure cycle, the 5th road is forming Loop, loop, float, tuck weaving structure cycle, the 7th road is loop, loop, float, float weaving structure cycle, the 2nd, 4th, 6th, 8th road is the bottom yarn, the 2nd, 4th , Route...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com