Post-furnace desulfurization method of semi-steel steelmaking converter

A steelmaking converter and post-furnace technology, which is applied in the field of post-furnace desulfurization of semi-steel steelmaking converters, can solve the problems of sulfur return and high oxygen activity, achieve low process cost, and avoid the effect of post-furnace sulfur return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

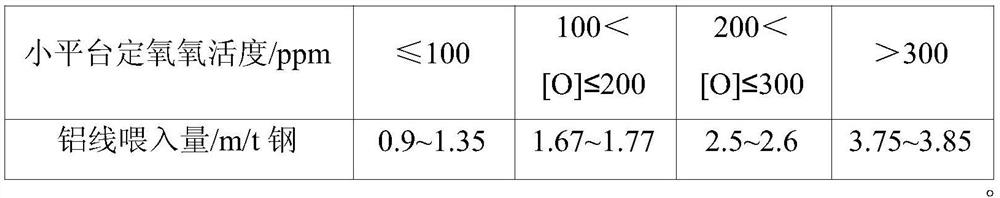

[0026] A 120t converter in a factory uses semi-steel steelmaking to smelt SPHC steel. The oxygen activity and sulfur content of molten steel are measured at the end of the converter. During the tapping process, calcium carbide is used for preliminary deoxidation. The ladle is blown with argon throughout the process. The amount of slag is controlled at no more than 20 mm; then the oxygen is fixed at the small platform station, and the aluminum wire (10 mm in diameter) is fed after the oxygen is fixed to adjust the degree of deoxidation, and the sulfur content after the treatment of the small platform is detected. The specific parameters and results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com