Acid salt corrosion-resistant conductive coating

A conductive coating and salt corrosion technology, applied in anti-corrosion coatings, conductive coatings, fire-resistant coatings, etc., can solve problems such as poor salt corrosion resistance, achieve stable electrical conductivity, good antistatic properties, and less pollution hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment relates to an anti-salt acid corrosion conductive coating and a preparation method thereof, the coating is composed of the following raw materials in parts by weight:

[0058] 46 parts of acrylic resin;

[0059] 20 parts of dammar resin;

[0060] Gallium arsenide 2 parts;

[0061] 6.5 parts of dead sea mud;

[0062] 4 parts perovskite powder;

[0063] 1 part of cellulose acetate butyrate;

[0064] 1.5 parts of brucite chopped fibers;

[0065] 0.3 parts of diethylene glycol dibenzoate;

[0066] 9 parts of dimethyl sulfoxide;

[0067] 3 parts snail slime;

[0068] Accelerator 0.65 parts;

[0069] 0.95 parts of crosslinking agent;

[0070] 0.5 parts of coupling agent;

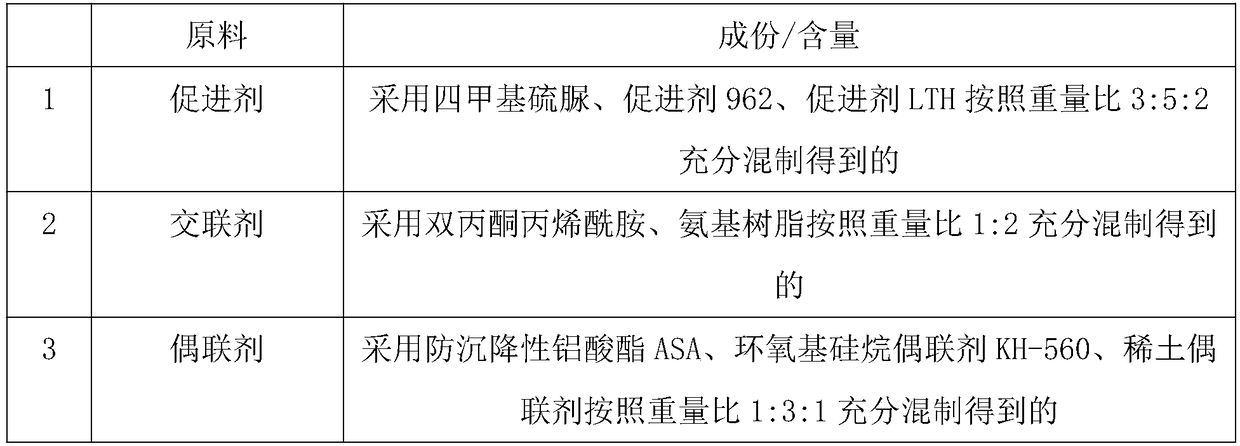

[0071] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 1 below:

[0072] Table 1

[0073]

[0074] The preparation method of present embodiment coating is carried out according to the following ste...

Embodiment 2

[0080] This embodiment relates to an anti-salt acid corrosion conductive coating and a preparation method thereof, the coating is composed of the following raw materials in parts by weight:

[0081] 48 parts of acrylic resin;

[0082] 21 parts of dammar resin;

[0083] Gallium arsenide 2.4 parts;

[0084] 7 parts dead sea mud;

[0085] 4.5 parts of perovskite powder;

[0086] 1.2 parts of cellulose acetate butyrate;

[0087] 1.8 parts of brucite chopped fibers;

[0088] 0.35 parts of diethylene glycol dibenzoate;

[0089] 10 parts of dimethyl sulfoxide;

[0090] 3.5 parts of snail mucus;

[0091] Accelerator 0.7 part;

[0092] 1.05 parts of crosslinking agent;

[0093] 0.55 parts of coupling agent;

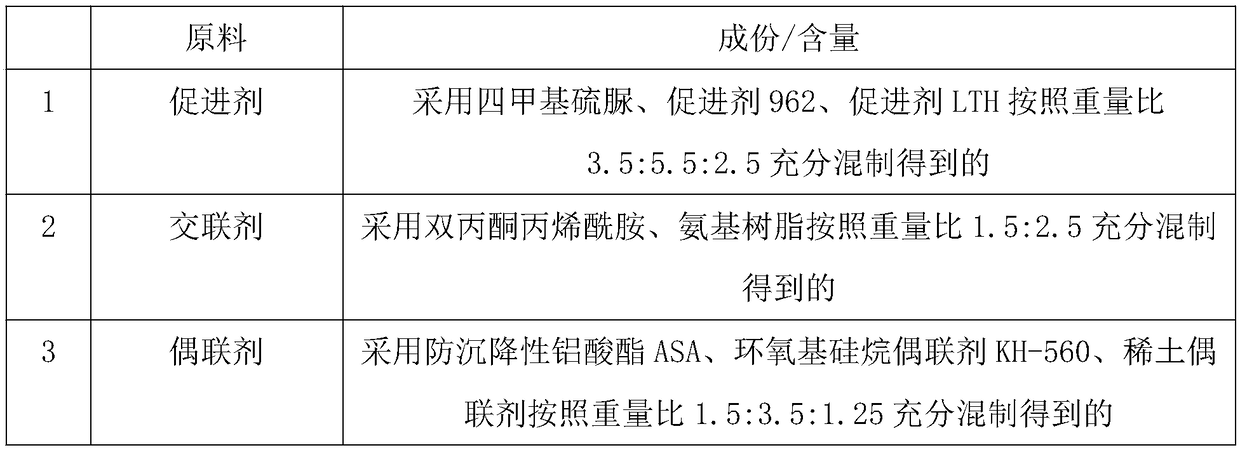

[0094] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 2 below:

[0095] Table 2

[0096]

[0097] The preparation method of present embodiment coating is carried out according to the ...

Embodiment 3

[0103] This embodiment relates to an anti-salt acid corrosion conductive coating and a preparation method thereof, the coating is composed of the following raw materials in parts by weight:

[0104] 49 parts of acrylic resin;

[0105] 22 parts of dammar resin;

[0106] Gallium arsenide 2.7 parts;

[0107] 7.5 parts of dead sea mud;

[0108] 5 parts perovskite powder;

[0109] 1.5 parts of cellulose acetate butyrate;

[0110] 2 parts of brucite chopped fiber;

[0111] 0.4 parts of diethylene glycol dibenzoate;

[0112] 11 parts of dimethyl sulfoxide;

[0113] 4 parts snail slime;

[0114] Accelerator 0.75 parts;

[0115] 0.15 parts of crosslinking agent;

[0116] 0.6 parts of coupling agent;

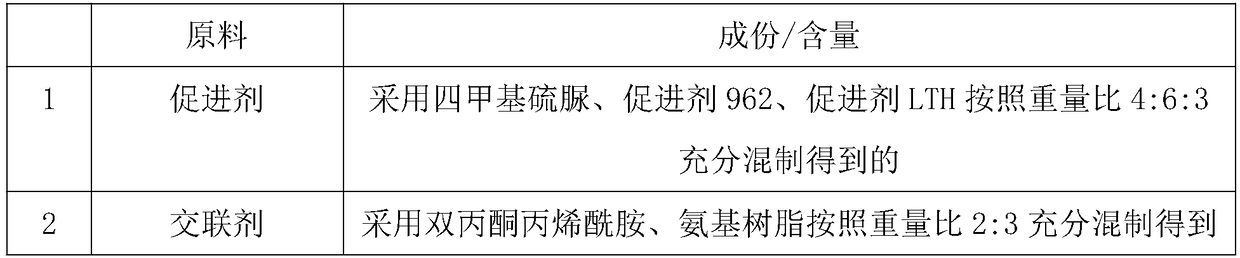

[0117] The selection and preparation of promotor, cross-linking agent and coupling agent in the present embodiment are shown in Table 3 below:

[0118] table 3

[0119]

[0120]

[0121] The preparation method of present embodiment coating is carried out according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com