Method for production of granular calcium dihydrogen phosphate by one-time granulation of concentrated phosphoric acid

A technology of calcium dihydrogen phosphate and concentrated phosphoric acid, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high material viscosity, shortened production process, and long process flow, and achieve high water-soluble phosphorus content, The effect of short production process and simple operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Using 30wt% grade phosphate rock for flotation, the MER value of the phosphor rock is 0.08. In the extraction reaction tank, add 98wt% industrial sulfuric acid and mixed acid, use the dihydric method to extract the wet dilute phosphoric acid, and the dihydric method to extract the P of phosphoric acid. 2 0 5 The concentration is 20wt%, the liquid-solid ratio is 2.0, and the reaction temperature is 75°C. Dilute phosphoric acid is concentrated by vacuum heat exchange after being settled, deweighted, defluorinated, purified and impurity removed to obtain feed-grade phosphoric acid. The obtained concentrated phosphoric acid has P / F=120. During the preparation of concentrated phosphoric acid, air stripping is used for defluorination, and the defluorination agent white carbon black is reacted in the air stripping defluorination device. The reaction time is 2 hours and the reaction temperature is 90°C.

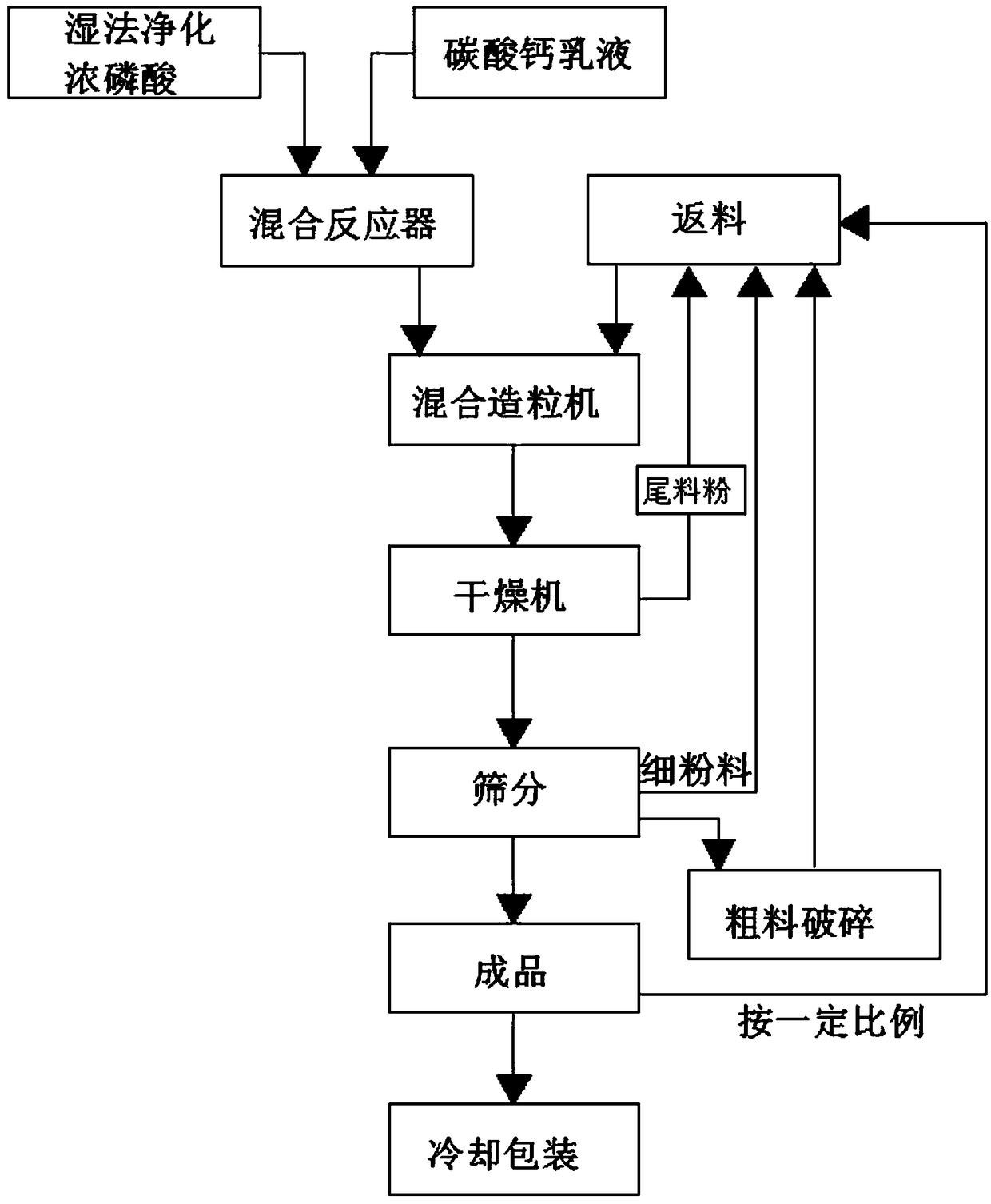

[0034] like figure 1 Shown a kind of method that utilizes concentrated...

Embodiment 2

[0047] The grade of 30.5wt% is used for flotation of phosphate rock, and the MER value of the phosphate rock is 0.078. In the extraction reaction tank, add 98wt% industrial sulfuric acid and mixed acid, use the dihydric method to extract the wet dilute phosphoric acid, and the dihydric method to extract the P of phosphoric acid. 2 0 5 The concentration is 25wt%, the liquid-solid ratio is 2.5, and the reaction temperature is 80°C. Dilute phosphoric acid is concentrated by vacuum heat exchange after being settled, deweighted, defluorinated and purified to obtain feed-grade phosphoric acid. P / F=128 in the obtained concentrated phosphoric acid. At this time, P 2 o 5 Concentration 50wt%. The process of preparing the concentrated phosphoric acid adopts air stripping defluorination, and reacts with defluorination agent white carbon black in the air stripping defluorination device, the reaction time is 2.2h, and the reaction temperature is 100°C.

[0048] The concentrated phosphor...

Embodiment 3

[0060] The phosphate rock with a grade of 31wt% is used for flotation, and the MER value of the phosphor rock is 0.06. In the extraction reaction tank, add 98wt% industrial sulfuric acid and mixed acid, use the dihydric method to extract the wet dilute phosphoric acid, and the dihydric method to extract the P of phosphoric acid. 2 0 5 The concentration is 30wt%, the liquid-solid ratio is 3.0, and the reaction temperature is 85°C. Dilute phosphoric acid is concentrated by vacuum heat exchange after being settled, deweighted, defluorinated and purified to obtain feed-grade phosphoric acid. P / F=130 in the obtained concentrated phosphoric acid. At this time, P 2 o 5 Concentration 55wt%. During the preparation of concentrated phosphoric acid, air stripping is used for defluorination, and the defluorination agent white carbon black is reacted in the air stripping defluorination device. The reaction time is 2.5 hours and the reaction temperature is 110°C.

[0061] like figure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com