Fast cutting and rewinding machine

A rewinding machine and cutting technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of inconsistent rewinding thickness and untimely cutting of paper rolls, etc., to achieve consistent rewinding thickness, High processing efficiency and simple rewinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

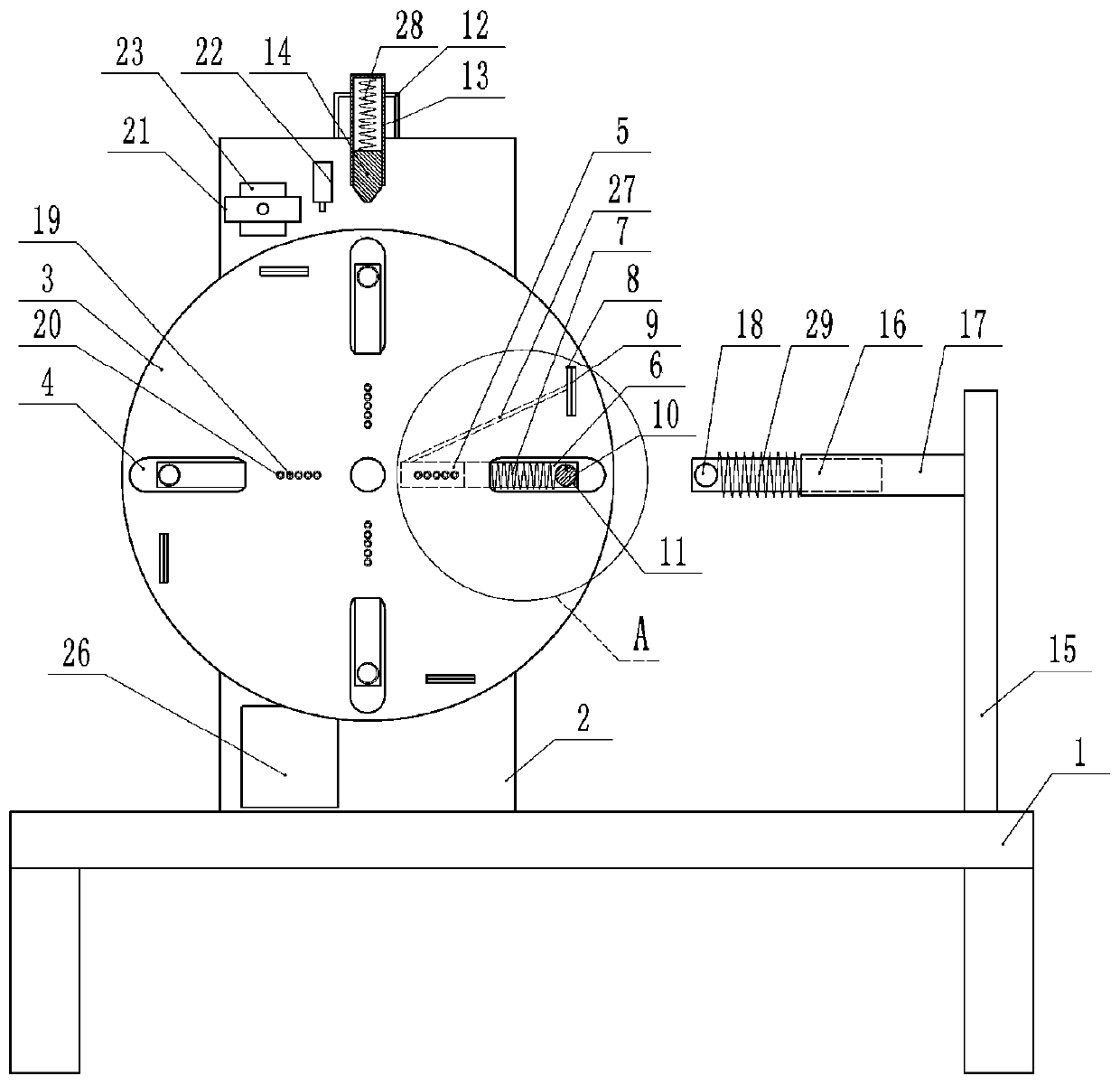

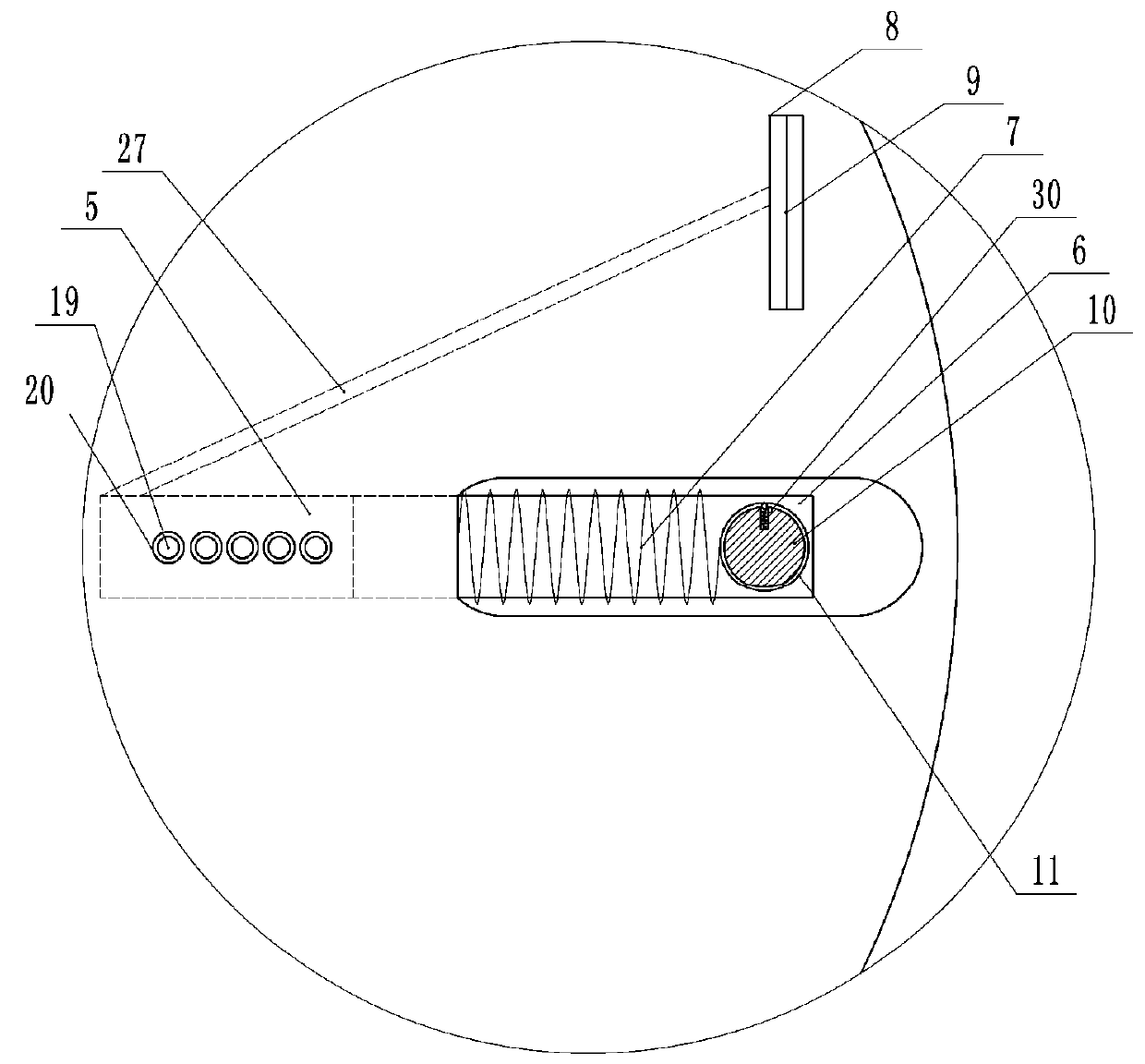

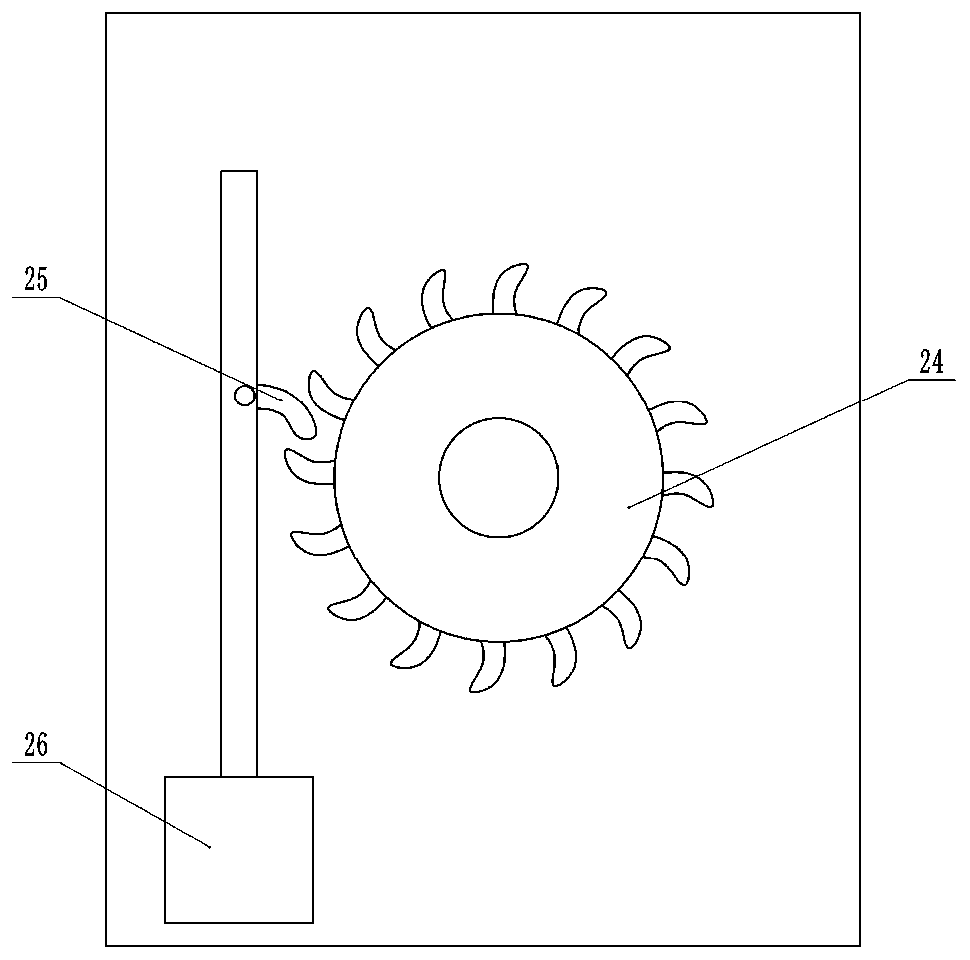

[0020] The reference signs in the drawings of the description include: workbench 1, frame 2, turntable 3, through groove 4, slide hole 5, ejector rod 6, first spring 7, chute 8, cutting knife 9, horizontal shaft 10, Sleeve 11, bracket 12, plastic box 13, top block 14, support rod 15, support rod 16, horizontal pipe 17, rotating shaft 18, vent hole 19, plug 20, push plate 21, blower 22, first cylinder 23, Ratchet 24, ratchet 25, second cylinder 26, tunnel 27, second spring 28, third spring 29, fourth spring 30.

[0021] Such as figure 1 As shown, a fast cutting and rewinding machine includes a workbench 1, a frame 2 and a motor (not drawn in the figure) are installed on the workbench 1, a rotating rod is installed on the frame 2 through a bearing, and the rotating rod is connected There are ratchet 24 and rotating disk 3 coaxial with the rotating rod, combined image 3 As shown, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com