Ferrous sulfate modified phosphate binder and preparation method thereof

A ferrous sulfate and phosphate technology, used in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of poor stability, low sand mold strength, insufficient moisture absorption resistance, etc., and achieve high moisture absorption resistance and improved strength. , the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

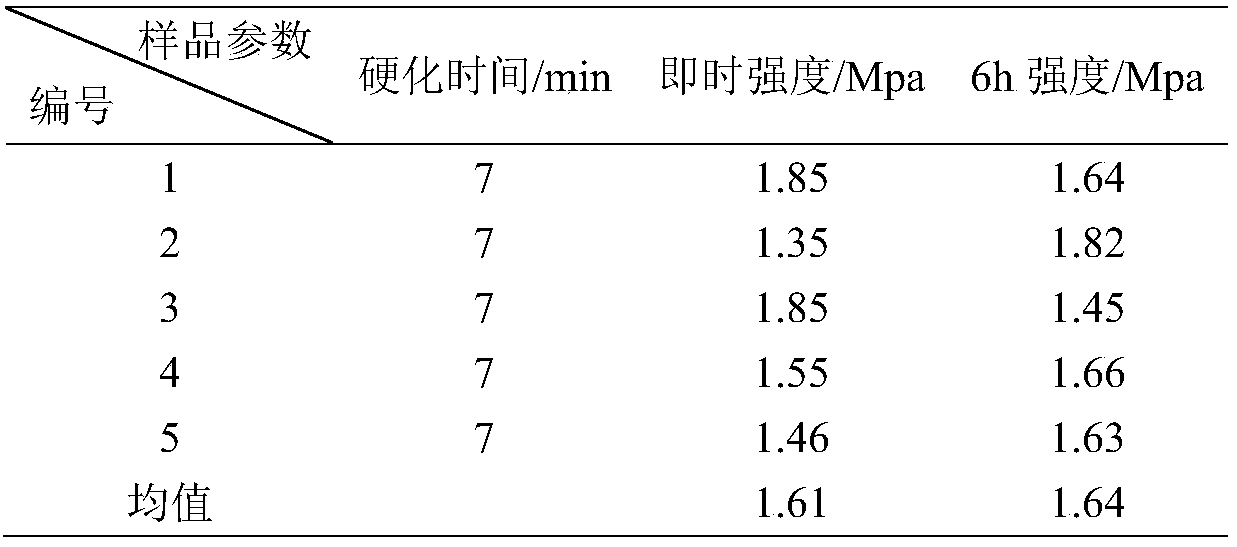

Embodiment 1

[0026] Preparation of Ferrous Sulfate Modified Phosphate Adhesive

[0027] Raw material ratio:

[0028] 338g of 85% industrial phosphoric acid, 68g of 320 mesh aluminum hydroxide powder, 12g of boric acid, 2g of silicic acid, 8g of magnesium oxide, 0.125g of ferrous sulfate, and 200g of water.

[0029] Preparation steps:

[0030] 1) Add phosphoric acid into the three-port reaction kettle, turn on the agitator and heater, and slowly heat to 200°C;

[0031] 2) After the temperature of phosphoric acid in the reaction kettle rises to 200°C, add aluminum hydroxide powder into the reaction kettle several times in small amounts; each addition needs to completely react the aluminum hydroxide powder added last time, and the process takes about 10 minutes; The sign of complete reaction is that the solution in the reactor is in a transparent state; then add 50g of water and stir to the preset temperature while heating, the process is about 1min;

[0032] 3) Add boric acid powder, cont...

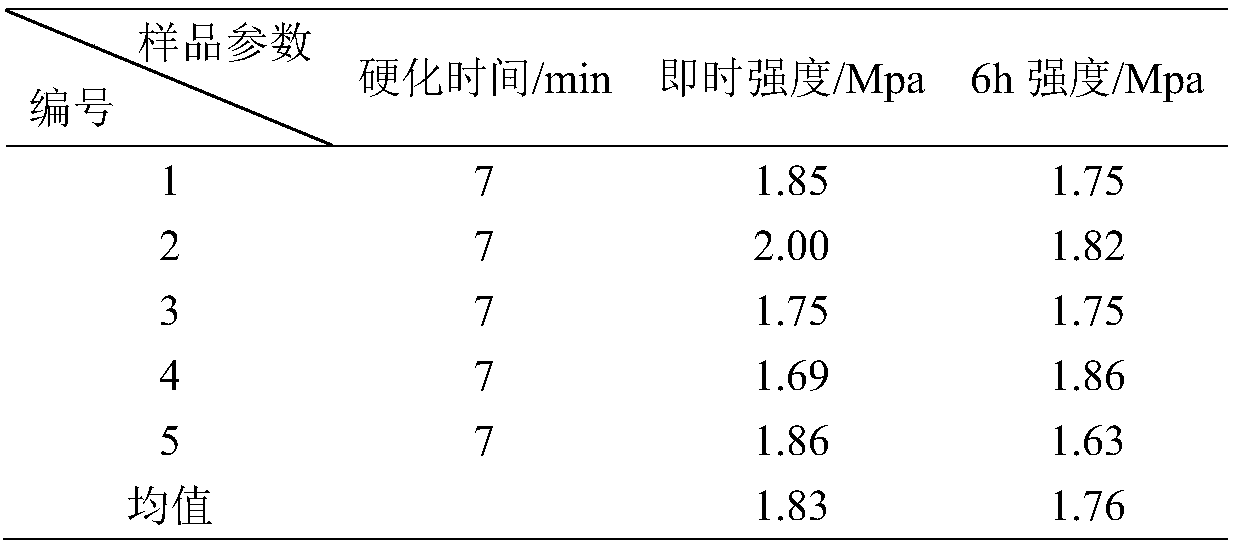

Embodiment 2

[0039] Preparation of Ferrous Sulfate Modified Phosphate Adhesive

[0040] Raw material ratio:

[0041] 338g of 85% industrial phosphoric acid, 68g of 320 mesh aluminum hydroxide powder, 12g of boric acid, 2g of silicic acid, 8g of magnesium oxide, 0.25g of ferrous sulfate, and 200g of water;

[0042] The preparation steps are the same as in Example 1.

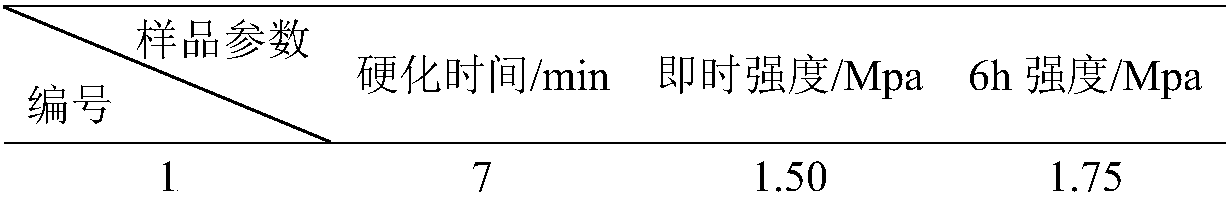

Embodiment 3

[0044] Preparation of Ferrous Sulfate Modified Phosphate Adhesive

[0045] Raw material ratio:

[0046] 338g of 85% industrial phosphoric acid, 68g of 320 mesh aluminum hydroxide powder, 12g of boric acid, 2g of silicic acid, 8g of magnesium oxide, 1g of ferrous sulfate, 200g of water;

[0047] The preparation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com