Core-shell type catalyst for directional catalytic conversion of biomass synthesis gas, and preparation of core-shell type catalyst

A catalytic conversion and synthesis gas technology, applied in the chemical field, can solve the problems of low hydrogenation conversion rate and achieve huge economic benefits, broad market application prospects, and good shape-selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

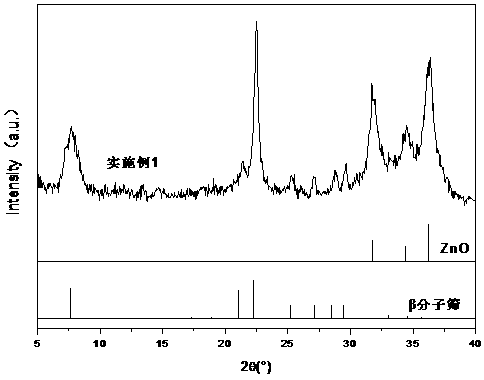

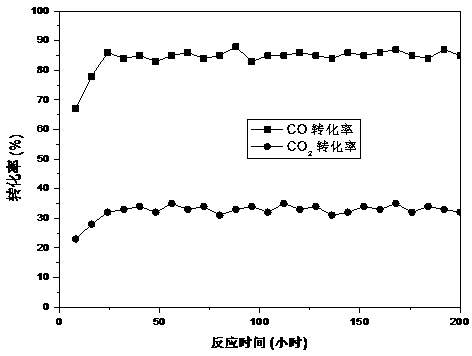

[0029] Embodiment 1: preparation and application of core-shell structure catalyst

[0030] A method for preparing a core-shell structure catalyst for directional catalytic conversion of biomass synthesis gas, comprising the following steps:

[0031] ①Preparation of composite metal oxides with small grains (sol-gel method): 17.65g Zn(NO 3 ) 2 ·6H 2 O, 5.62gZrO(NO 3 ) 2 and 1.76g Ce(NO 3 ) 3 ·6H 2 The aqueous solution of O was stirred evenly, mixed with 15g of citric acid at 80°C, and then the pH value was adjusted to 8-9 with ammonia water to obtain a gel, dried at 100°C for 12 hours, and calcined at 500°C for 4 hours to obtain a small-grain composite metal oxide .

[0032] ②Surface modification of the metal oxide obtained in step ①: supersaturated impregnation with tetraethylammonium hydroxide (TEAOH)—condensation and reflux; use 0.1mol / L TEAOH of small-grain composite metal oxide at 55°C The solution was condensed and refluxed for 38 hours, filtered, and dried at 100...

Embodiment 2

[0042] Embodiment 2: preparation and application of core-shell structure catalyst

[0043] Different from Example 1, the preparation method of the core-shell structure catalyst for the directional catalytic conversion of biomass synthesis gas comprises the following steps:

[0044] ①Preparation of composite metal oxides with small crystal grains (uniform urea precipitation method): 17.65g Zn(NO 3 ) 2 ·6H 2 O, 5.62gZrO(NO 3 ) 2 , 1.76g Ce(NO 3 ) 3 ·6H 2 O and 40g of urea were dissolved in 200mL of water, and put into a stainless steel reactor lined with polytetrafluoroethylene, and reacted at 80°C for 24h to obtain a small-grain composite metal oxide.

[0045]②Surface modification of the metal oxide obtained in step ①: supersaturated impregnation with cetyltrimethylammonium bromide (CTAB)—condensation and reflux; / L CTAB solution was condensed and refluxed for 48 hours, filtered, and dried at 100° C. for 10 hours to obtain a surface-modified small-grain composite metal ...

Embodiment 3

[0054] Embodiment 3: preparation core-shell structure catalyst, contrast CO hydrogenation conversion catalyst and application

[0055] Different from Example 1, the preparation method of the core-shell structure catalyst for the directional catalytic conversion of biomass synthesis gas comprises the following steps:

[0056] ①Preparation of composite metal oxides with small grains (co-precipitation method): 25.30g Zn(NO 3 ) 2 ·6H 2 O, 16.25gCo(NO 3 ) 2 ·6H 2 O and 3.00g In(NO 3 ) 3 The aqueous solution was co-precipitated with 1mol / L ammonia solution, washed until neutral, dried at 120°C for 12h, and calcined at 550°C for 6h to obtain a small-grain composite metal oxide.

[0057] ② Surface modification of the metal oxide obtained in step ①: using cetyltrimethylammonium bromide (CTAB) supersaturated impregnation method—condensation and reflux; / L of CTAB solution was refluxed for 1 h, filtered, and dried at 100° C. for 12 h to obtain a surface-modified small-grain compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com