Anode and cathode base bands, anode and cathode pieces, lithium ion battery with high power capacity and preparation method of lithium ion battery

A technology for lithium-ion batteries, positive and negative pole pieces, applied in battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve problems such as difficulty in continuous normal production, increased production difficulty, and unstable production. Achieve the effect of improving the production pass rate, not easy to be oxidized, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Further, the present invention also provides a method for preparing the above-mentioned high-capacity lithium-ion battery, the method comprising the following steps: respectively coating the positive and negative active materials on the positive and negative base tapes, drying and rolling to obtain the positive and negative electrodes The pole piece is wound, injected with a lithium hexafluorophosphate solution with a concentration of 0.5-5 mol / L, and converted to volume to obtain a lithium-ion battery.

[0022] Wherein, in the above-mentioned method for preparing a high-capacity lithium-ion battery, the concentration of the lithium hexafluorophosphate solution is 0.5-2 mol / L, such as 1 mol / L.

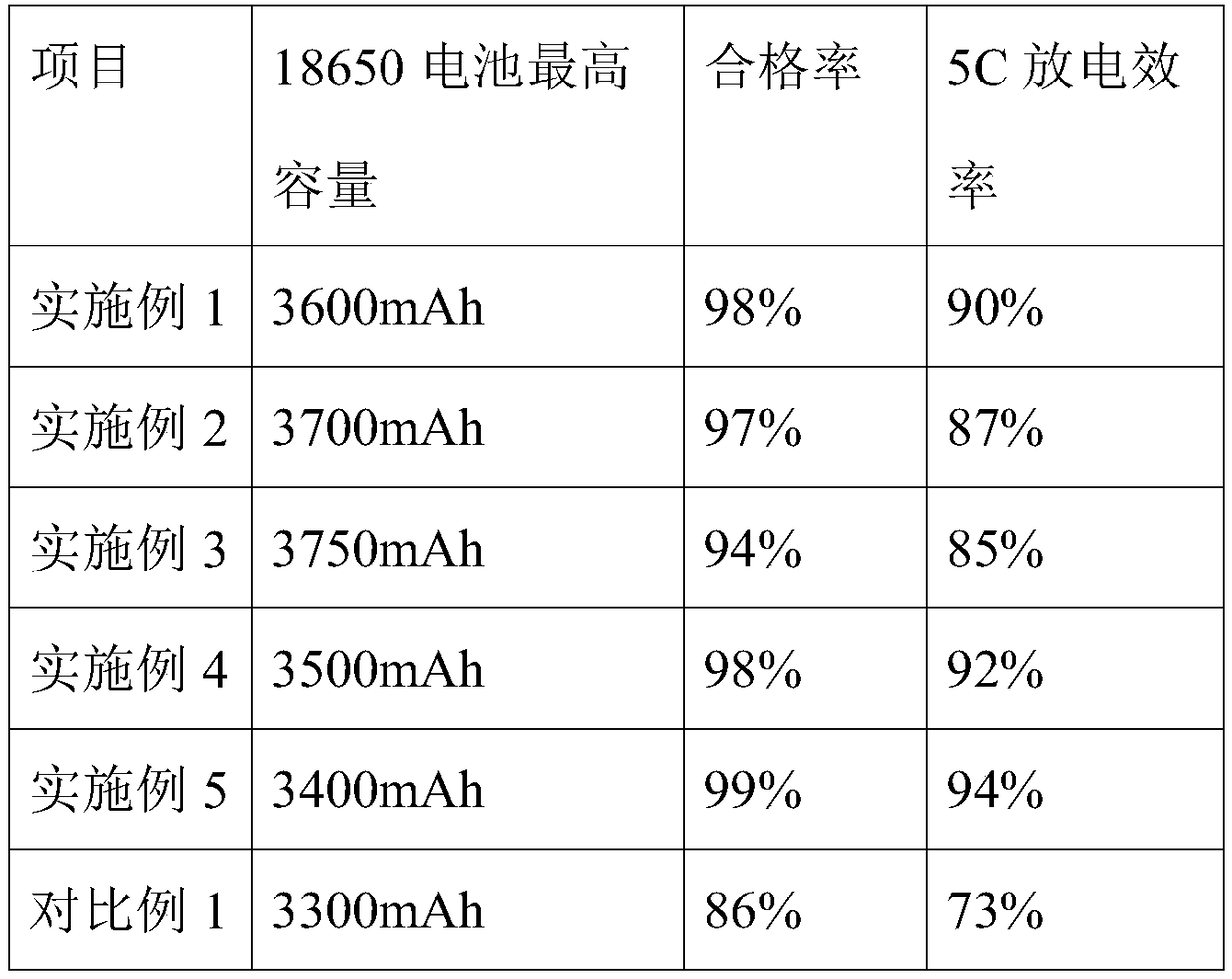

[0023] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments. The following examples are only to illustrate and explain the present invention, but should not be construed as limiting the protection sco...

Embodiment 1

[0026] The positive and negative electrodes all adopt 0.5 micron thick titanium foil with holes, the porosity (pore area / titanium foil total area is 5%), the positive active material is lithium cobaltate, and the negative active material is graphite. Coating on titanium foil, drying, and rolling to obtain a new type of pole piece, winding the pole piece, injecting 1mol / L lithium hexafluorophosphate organic solution, and forming a volume to obtain a new type of 18650 battery.

Embodiment 2

[0028] The positive and negative electrodes all adopt 0.5 micron thick titanium foil with holes, the porosity (pore area / titanium foil total area is 15%), the positive active material is lithium cobaltate, and the negative active material is graphite. Coating on titanium foil, drying, and rolling to obtain a new type of pole piece, winding the pole piece, injecting 1mol / L lithium hexafluorophosphate organic solution, and forming a volume to obtain a new type of 18650 battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com