Coating device

A technology of coating equipment and coating head, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as unrecyclable reuse, production loss, liquid crystal waste, etc., to avoid frequent replacement of glass bottles, reduce production loss, The effect of reducing waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

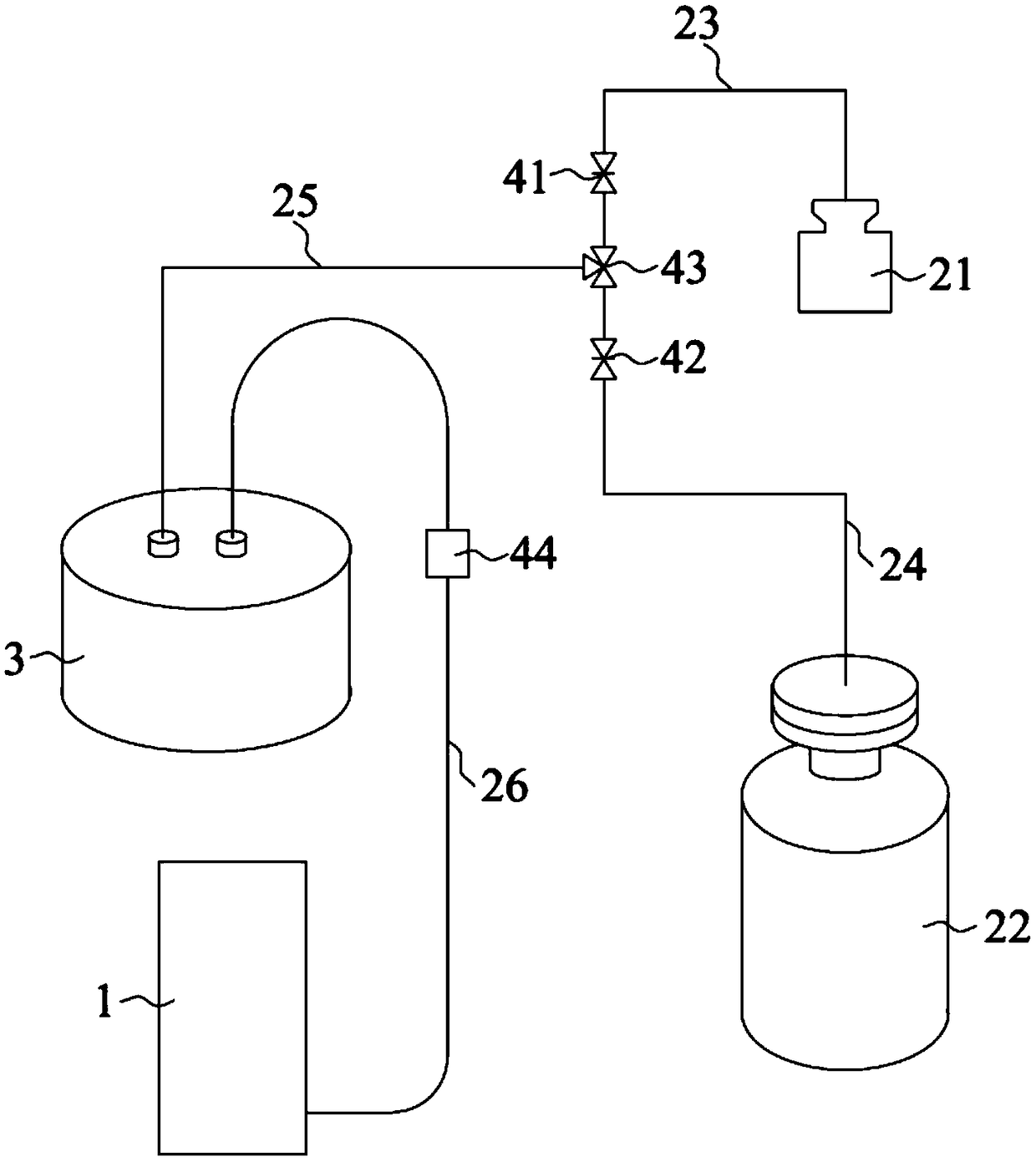

[0024] like figure 1 As shown, this embodiment provides a coating device, including a coating head 1 and a supply part for supplying raw materials into the coating head 1 . The raw material is stored in the supply part. When working, the raw material enters the coating head 1 through the pipeline, and the coating head 1 can be coated on the workpiece by dripping or spraying to complete the raw material coating. Wherein, the coating equipment can be used to coat the liquid crystal on the glass substrate during the processing of the liquid crystal display device. For the convenience of introduction, this embodiment takes liquid crystal coating as an examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com