Method for promoting wood dust enzymolysis through combined pretreatment

A technology of wood chips and enzymolysis, applied in fermentation and other directions, can solve the problems of poor pretreatment effect of wood chips and low enzymolysis yield, achieve co-production of xylo-oligosaccharides, improve the degree of hydrophilic modification, and strengthen the mitigation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] An efficient combined pretreatment method for poplar wood chips, the steps are as follows:

[0020] (1) Weigh 200g of poplar wood chips with absolute dry weight, and treat them with 5% (v / v) acetic acid aqueous solution at a solid-to-liquid ratio of 1:10 (g / mL, the same below), at 170°C for 0.5h.

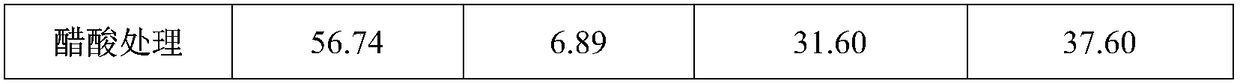

[0021] (2) After the acetic acid treatment finishes, carry out solid-liquid separation, the treatment liquid that produces is the acetic acid aqueous solution that is rich in xylo-oligosaccharide, and its xylo-oligosaccharide concentration and yield are shown in Table 1; The solid residue that it produces is washed with water, filtered Finally, poplar sawdust treated with acetic acid was obtained, and the analysis of its main components is shown in Table 1.

[0022] Wherein, xylo-oligosaccharide yield (%)=(oligosaccharide concentration in hydrolyzate g / L×10)÷(1000g×xylan content)×100%. In the formula: 1 is the total volume of acetic acid treatment, L; 1000 is the absolute dr...

Embodiment 2

[0037] An efficient combined pretreatment method for poplar wood chips, the steps are as follows:

[0038] (1) Weigh 200g of poplar wood chips with absolute dry weight, and treat them with 5% (v / v) acetic acid aqueous solution at a solid-to-liquid ratio of 1:10 (g / mL, the same below), at 170°C for 0.5h.

[0039] (2) After the acetic acid treatment is completed, solid-liquid separation is carried out, and the treatment liquid and solid residue are collected respectively; the solid residue is washed with water and filtered for later use.

[0040] (3) Take by weighing 20g of the above-mentioned acetic acid-treated poplar wood chips with a dry weight, use 30g / L sodium hydroxide aqueous solution, the amount of polyethylene glycol diglycidyl ether is 5-30%, and the solid-to-liquid ratio is 1:10g / mL, Co-processed at 70°C for 3h. Among them, the quality of polyethylene glycol diglycidyl ether is calculated by absolute dry weight of poplar wood chips treated with acetic acid.

[0041...

Embodiment 3

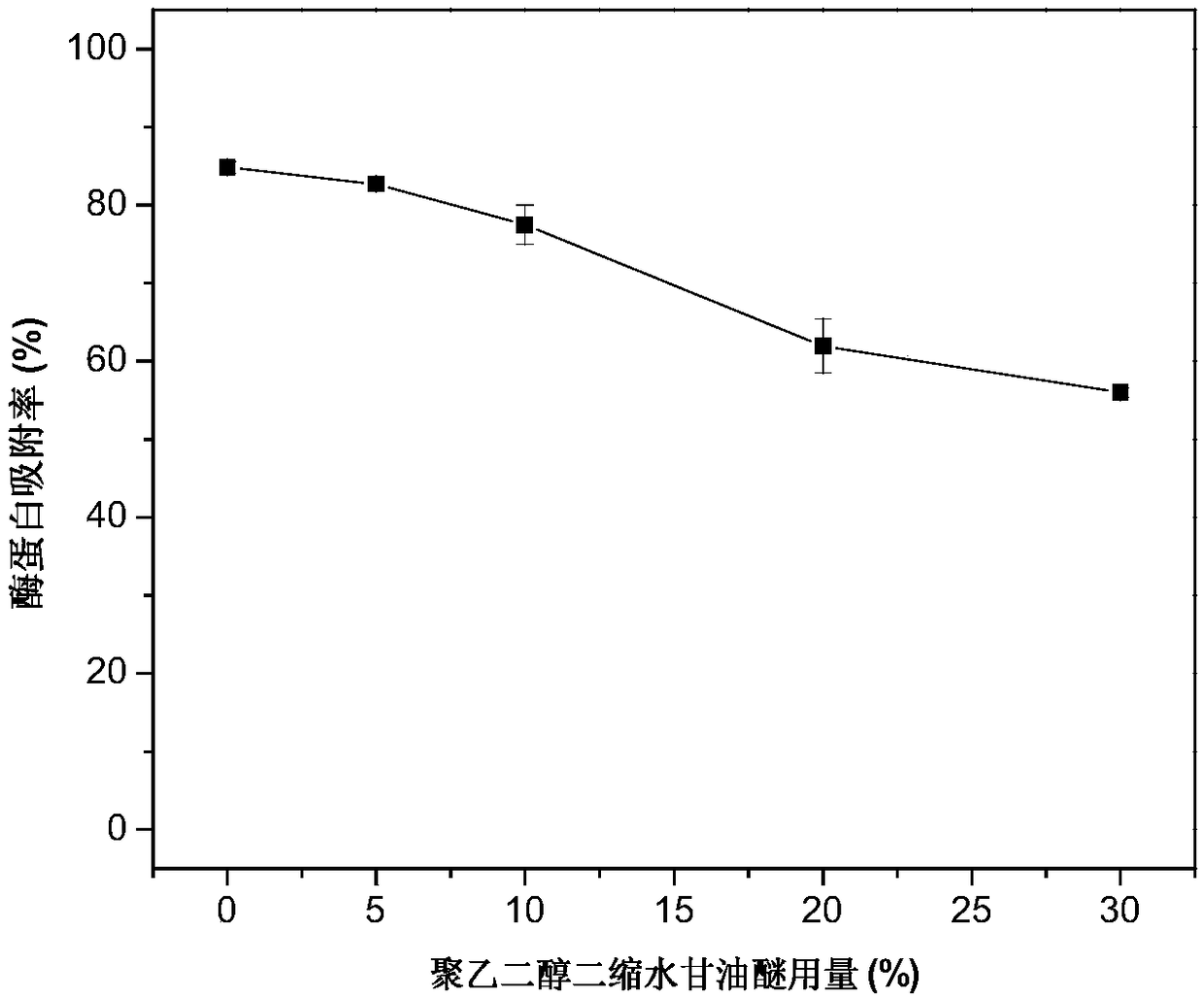

[0048] A high-efficiency combined pretreatment method for poplar wood chips, cellulase adsorption test, the specific steps are as follows:

[0049] (1) Weigh 200g of poplar wood chips with absolute dry weight, and treat them with 5% (v / v) acetic acid aqueous solution at a solid-to-liquid ratio of 1:10 (g / mL, the same below), at 170°C for 0.5h.

[0050] (2) After the acetic acid treatment is completed, solid-liquid separation is carried out, and the treatment liquid and solid residue are collected respectively; the solid residue is washed with water and filtered for later use.

[0051] (3) Take by weighing 20g of the above-mentioned acetic acid-treated poplar wood chips with a dry weight, use 30g / L sodium hydroxide aqueous solution, the amount of polyethylene glycol diglycidyl ether is 5-30%, and the solid-to-liquid ratio is 1:10g / mL, Co-processed at 70°C for 3h.

[0052] (4) After the combined treatment, the materials are collected by washing with water and filtered, and used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com