Mold releasing agent for phosphogypsum concrete prefabricated component

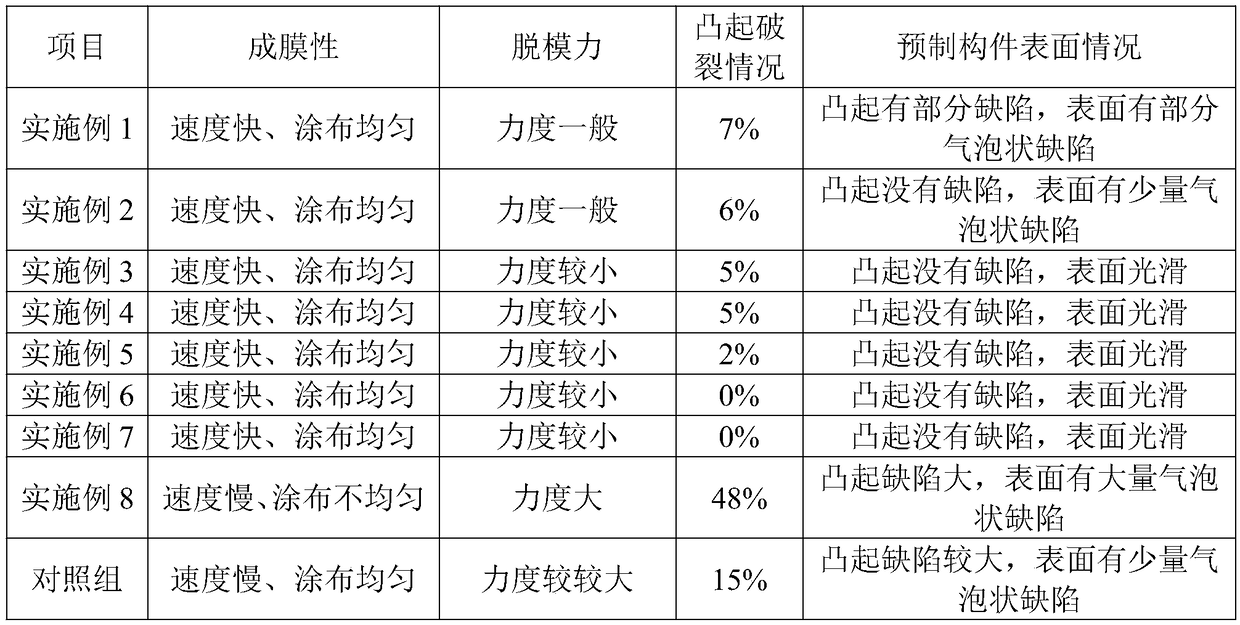

A prefabricated component and concrete technology, which is applied in the petroleum industry, lubricating composition, etc., can solve the problems of bubble-like defects on the surface of prefabricated components, rupture of concrete prefabricated components, and poor scour resistance, and achieves easy promotion, strong mechanical properties, Effect of small demoulding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment proposes a release agent for phosphogypsum concrete prefabricated components, which consists of the following components by weight:

[0025] 15 parts of vegetable oil, 0.5 parts of vinyl bis stearic acid amide powder, and 0.1 part of graphene powder.

[0026] Wherein, the particle size of vinyl bis stearic acid amide powder is 100 mesh.

Embodiment 2

[0028] This embodiment proposes a release agent for phosphogypsum concrete prefabricated components, which consists of the following components by weight:

[0029] 18 parts of vegetable oil, 1 part of vinyl bis stearic acid amide powder, 0.4 part of graphene powder.

[0030] Wherein, the particle size of vinyl bis stearic acid amide powder is 150 mesh.

Embodiment 3

[0032] This embodiment proposes a release agent for phosphogypsum concrete prefabricated components, which consists of the following components by weight:

[0033] 20 parts of vegetable oil, 1.4 parts of vinyl bis stearic acid amide powder, and 0.6 parts of graphene powder.

[0034] Wherein, the particle size of vinyl bis stearic acid amide powder is 200 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com