After-treatment system for kitchen wastes and method

A technology for kitchen waste and insect excrement, applied in the field of kitchen waste post-processing system, can solve the problems of environmental damage, high labor cost, long cost recovery period, etc., and achieve the effect of thorough fertilizer fermentation and rich fertilizer nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

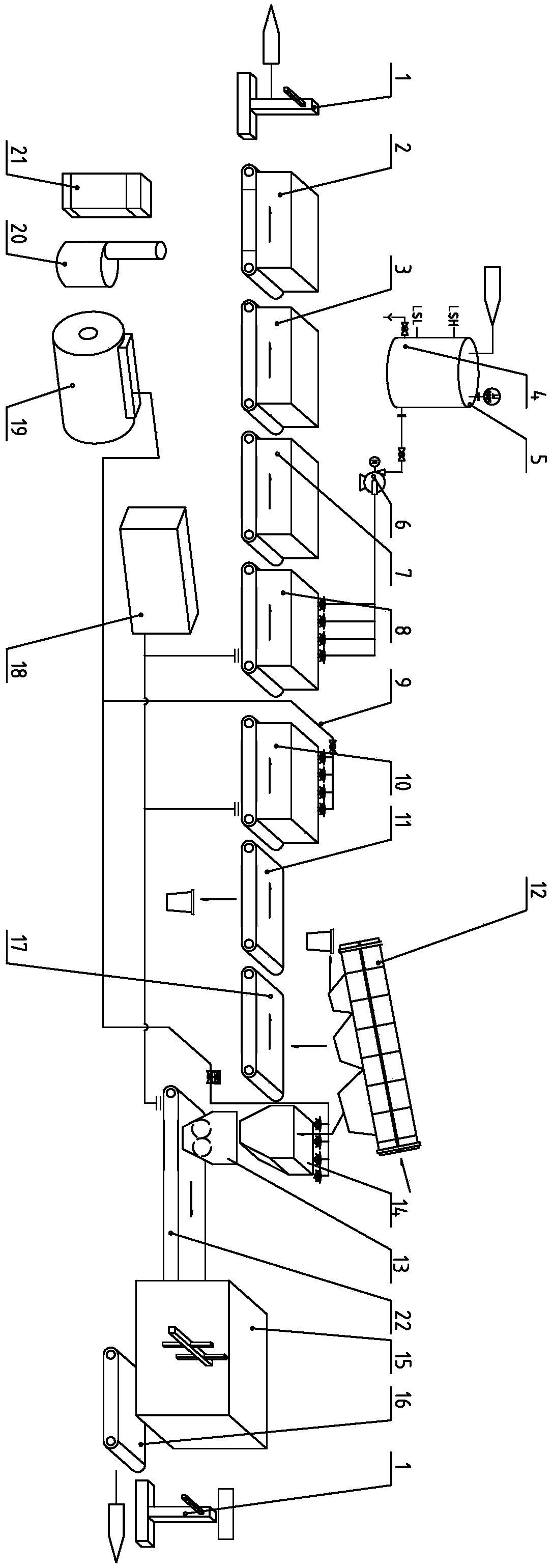

[0021] The invention patent utilizes the PLC program of the electric control system, instruments and meters, and automatic valves to control the motors of all equipment, so that the operation is stable and reliable, the efficiency is improved, the labor cost is reduced, and problems caused by manual errors are avoided.

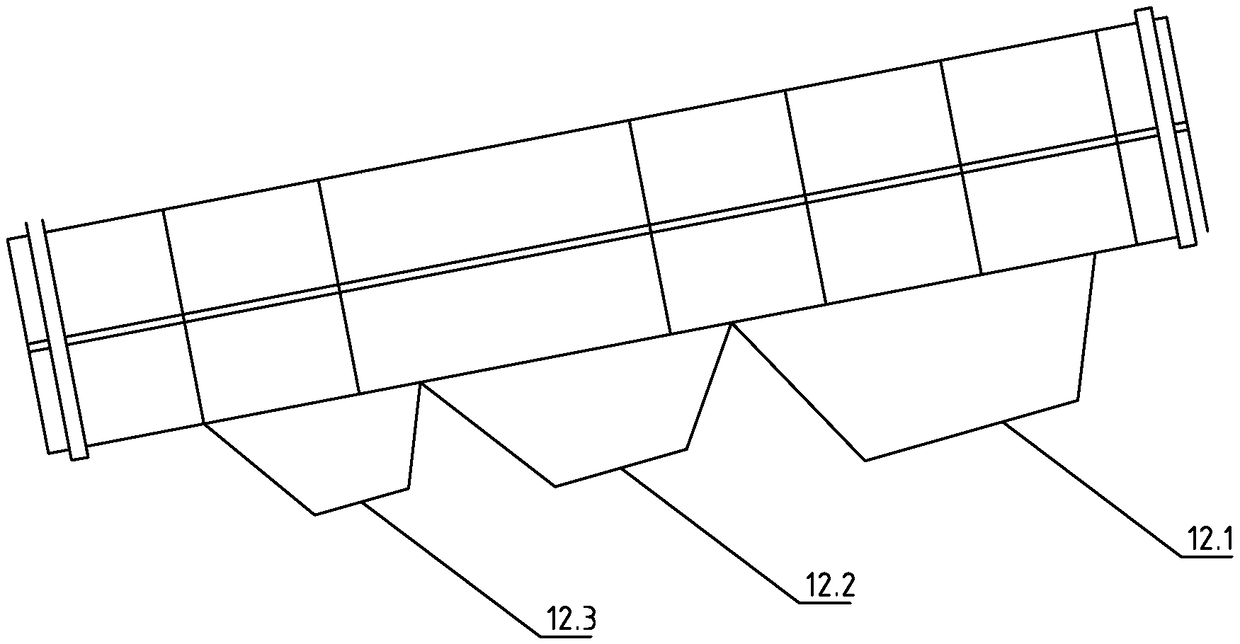

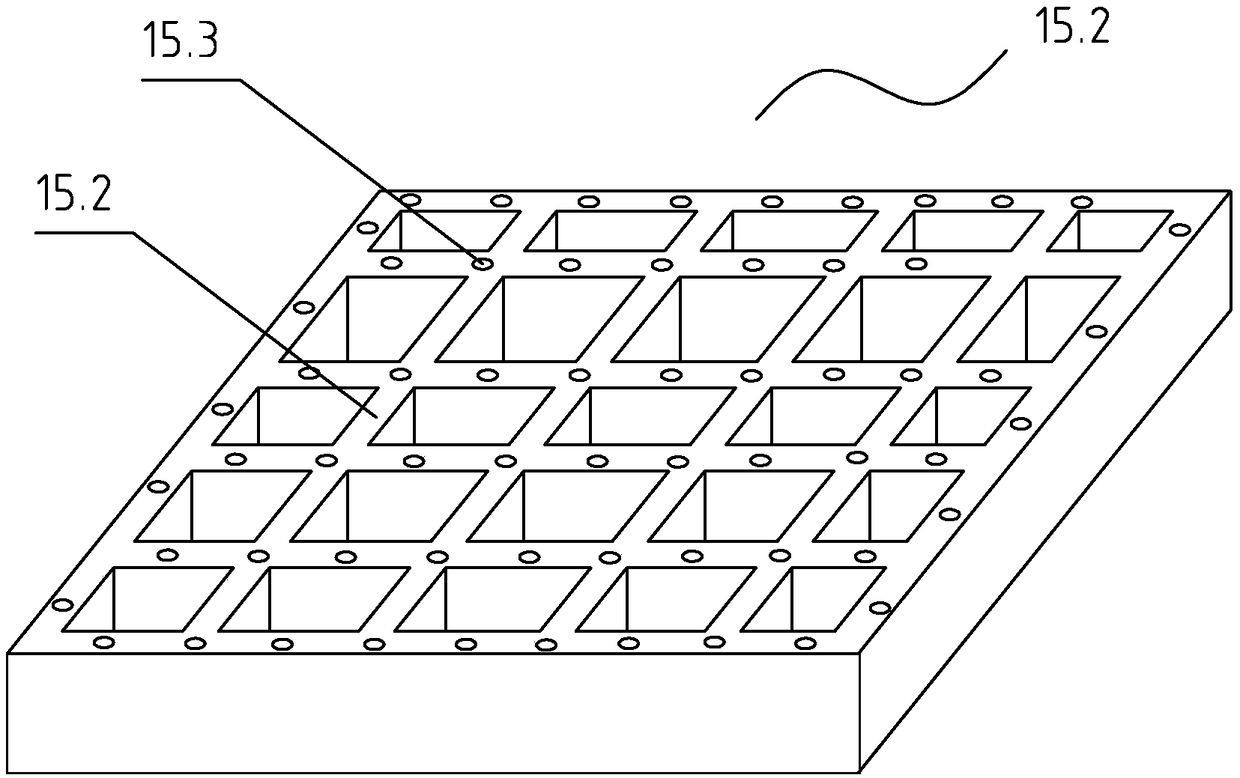

[0022] as attached figure 1 As shown, a food waste post-processing system of the present invention includes an insect excrement drum screen 12, and an insect excrement separation section 12.1, an insect separation section 12.2 and a waste separation section 12.3 are arranged in the insect excrement drum screen. The insect excrement separated by the insect excrement separation section enters the conditioning machine 14, and the discharge port of the conditioning machine is connected with a pulverizer 13, and the excrement conveying device 22 is arranged below the discharge port of the pulverizer, and the feces conveying device The discharge end of the aerobic f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com