A locally reinforce porous ear bracket and a manufacturing method thereof

A technology of local enhancement and manufacturing method, which is applied in the direction of additive manufacturing, manufacturing tools, additive processing, etc., can solve the problems of low forming precision of FDM process, inconvenient surface polishing treatment, and reduce the hardness of bracket support, so as to reduce the exposure of bracket, Facilitate tissue growth and reduce contracture response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

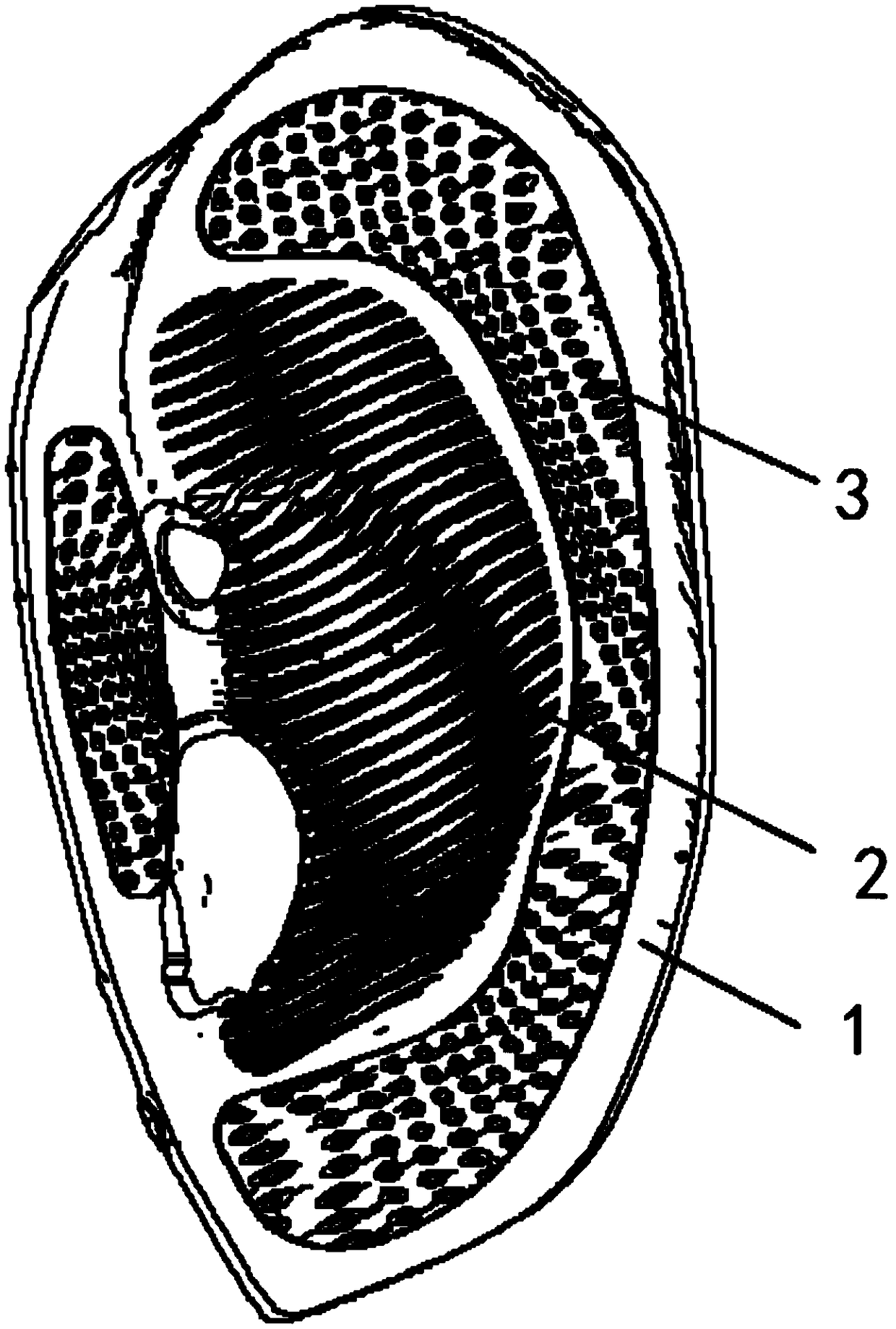

[0042] join figure 1 , the present invention provides an ear support, which includes an ear support body 1 and a reinforcing mesh structure 2; the ear support body 1 is uniformly provided with a plurality of small holes 3 along its outer contour;

[0043] The inner contour of the ear support body 1 is provided with a reinforcing mesh structure 2 matching the shape of the inner contour; the ear support body 1 is made of silicone material. It should be emphasized that:

[0044] 1. The outer contour of the ear support body includes the scaphoid, the tragus, and the earlobe; the inner contour of the ear support body includes the concha cavity, the concha concha, and the triangular fossa.

[0045] 2. Silica gel is used as a scaffold material for human organoplasty due to its good histocompatibility and elasticity (see reference [1] Hakelius L, Ohlsén L. Tendency to capsular contracture around smooth and textured gel-filled silicone mammary implants: a five-year follow-up[J].Plast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com