Stainless steel cup and surface baking paint and baking method thereof

A technology of stainless steel and baking varnish layer, which is applied in the field of baking varnish and baking varnish technology, can solve the problems of poor anti-fingerprint performance and poor anti-scratch performance, achieve good wear resistance and anti-scratch performance, improve anti-fingerprint performance, improve anti- The effect of scratch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

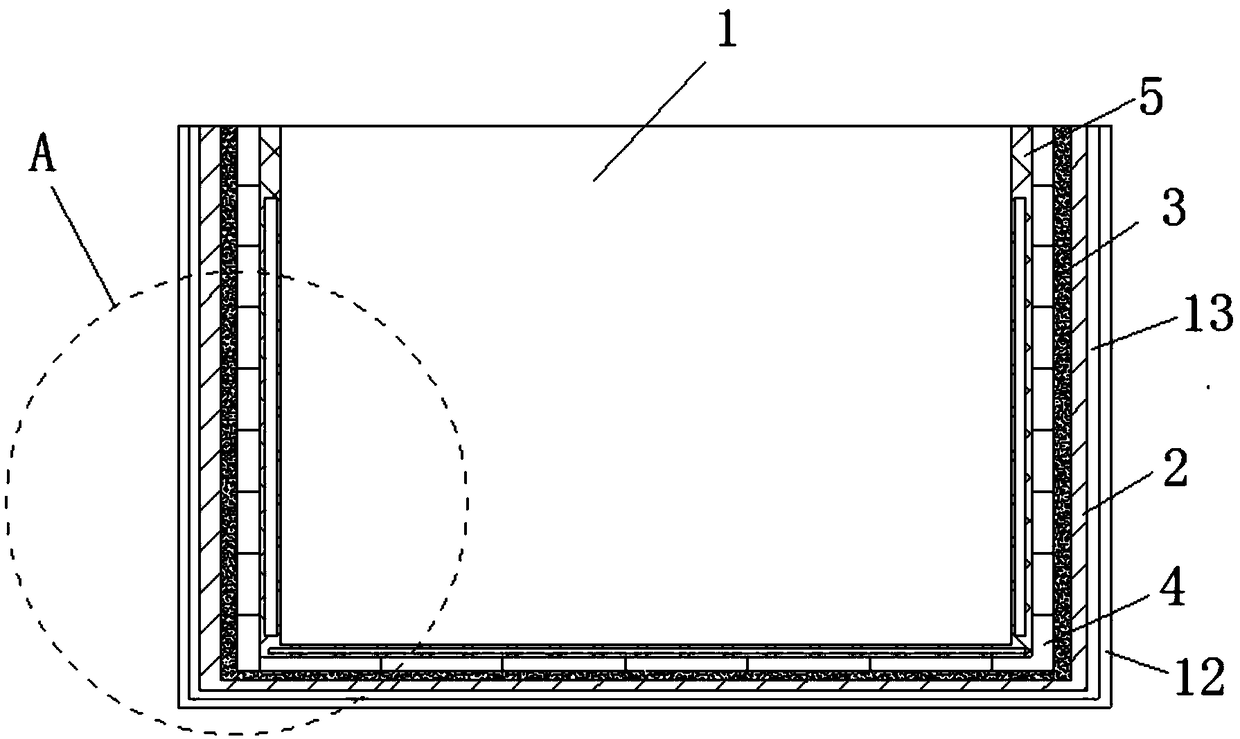

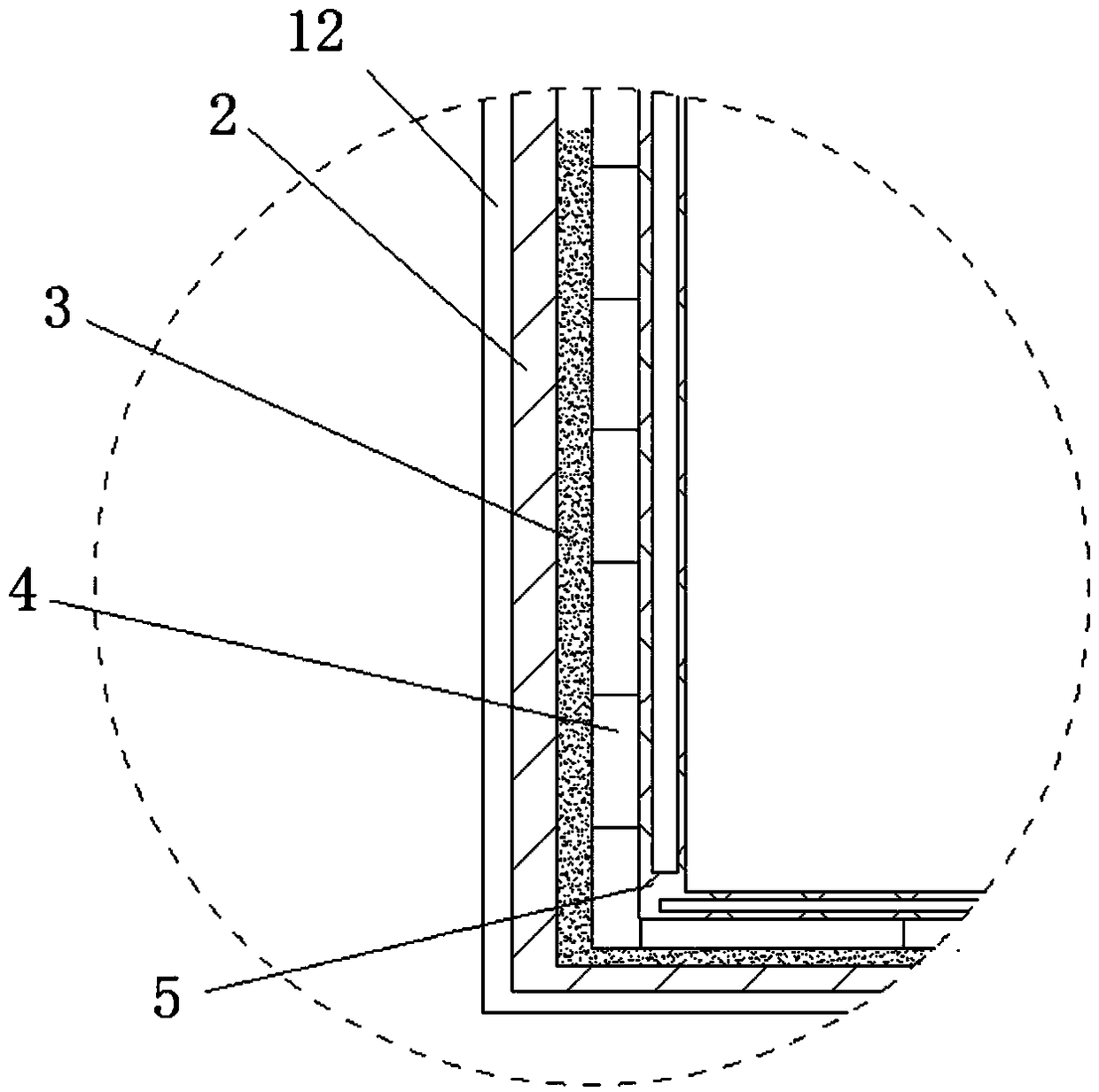

[0039] The baking varnish layer 2 is composed of the following components by weight: 12-16 parts of modified polyurethane acrylate, 10-12 parts of nanoparticles, 12-16 parts of polyether ether ketone resin, 10-12 parts of filler, organic pigment 20-26 parts, 0.8-1 part of defoamer, 0.4-0.8 parts of leveling agent, 1.6-6 parts of wetting agent, 2-3 parts of curing agent, 2-4 parts of dispersing agent, 30-40 parts of water.

[0040] The filler is one of silicon dioxide, aluminum oxide, titanium dioxide or barium sulfate.

[0041] The wetting agent is one of ethanol, propylene glycol, glycerin or dimethyl sulfoxide.

[0042] The curing agent is one of aliphatic amine, aromatic amine, modified amine or low molecular weight polyamide.

[0043] The modified urethane acrylate is a modified urethane acrylate containing carbon-carbon double bonds and perfluoropolyether functional groups.

[0044] The nanoparticles are one of silicon dioxide or calcium carbonate.

[0045] The water i...

Embodiment 2

[0054] The baking varnish layer 2 is composed of the following components in parts by weight: 16 parts of modified polyurethane acrylate, 12 parts of nanoparticles, 16 parts of polyetheretherketone resin, 12 parts of filler, 26 parts of organic pigment, and 1 part of defoamer , 0.8 parts of leveling agent, 6 parts of wetting agent, 3 parts of curing agent and 4 parts of dispersing agent, 40 parts of water.

[0055] The filler is one of silicon dioxide, aluminum oxide, titanium dioxide or barium sulfate.

[0056] The wetting agent is one of ethanol, propylene glycol, glycerin or dimethyl sulfoxide.

[0057] The curing agent is one of aliphatic amine, aromatic amine, modified amine or low molecular weight polyamide.

[0058] The modified urethane acrylate is a modified urethane acrylate containing carbon-carbon double bonds and perfluoropolyether functional groups.

[0059] The nanoparticles are one of silicon dioxide or calcium carbonate.

[0060] The water is deionized wate...

Embodiment 3

[0069] The baking varnish layer 2 is composed of the following components in parts by weight: 14 parts of modified polyurethane acrylate, 12 parts of nanoparticles, 14 parts of polyetheretherketone resin, 12 parts of filler, 22 parts of organic pigment, and 0.8 part of defoamer , 0.6 parts of leveling agent, 2 parts of wetting agent, 2.5 parts of curing agent, 2 parts of dispersing agent, 40 parts of water.

[0070] The filler is one of silicon dioxide, aluminum oxide, titanium dioxide or barium sulfate.

[0071] The wetting agent is one of ethanol, propylene glycol, glycerin or dimethyl sulfoxide.

[0072] The curing agent is one of aliphatic amine, aromatic amine, modified amine or low molecular weight polyamide.

[0073] The modified urethane acrylate is a modified urethane acrylate containing carbon-carbon double bonds and perfluoropolyether functional groups.

[0074] The nanoparticles are one of silicon dioxide or calcium carbonate.

[0075] The water is deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com