Board with improved compression strength

A technology of ring pressing and fiberboard, applied in the field of corrugated fiberboard, which can solve the problems of increasing the cost of final products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

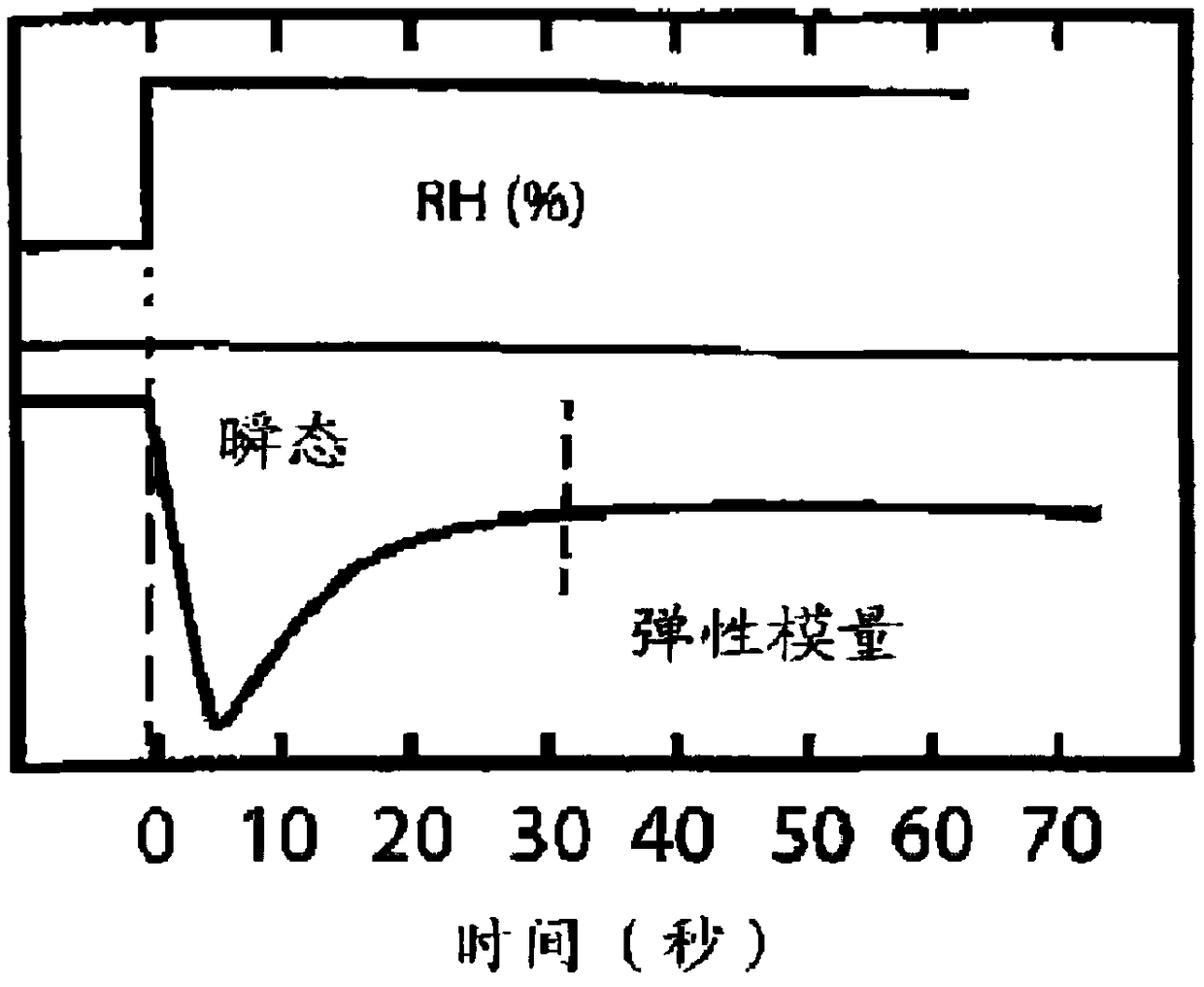

[0073] The experiment was carried out on a test paper machine. The pulp mix comprised 70% wet hardwood and 30% dry softwood pulp. Refining was at pH 7-8 and after refining the Schobel-Rigler (SR) values were 23-25 for both pulp qualities. The machine speed is 28m / min. The pilot paper machine produced moldable board. The panels were stored at a moisture content of 85% prior to production of the moldable product, and thus this example relates to high moisture performance.

[0074] The weight of fiberboard is 330g / m 2 , and the target thickness is 450 μm.

[0075] The added fixing chemicals were 1 kg / t of wet strength agent (leveling box 1), 2 kg / t of starch (leveling box 3) and 1,5 kg / t of AKD (suction side of the fan pump). The SR value was determined using the ISO5267 / 1 standard.

[0076] Table 1 shows the effect of adding MFC to the pulp. At 50% and 85% relative humidity (RH), the geometric tensile index and fracture tenacity of the MFC-containing paperboard increa...

Embodiment 2

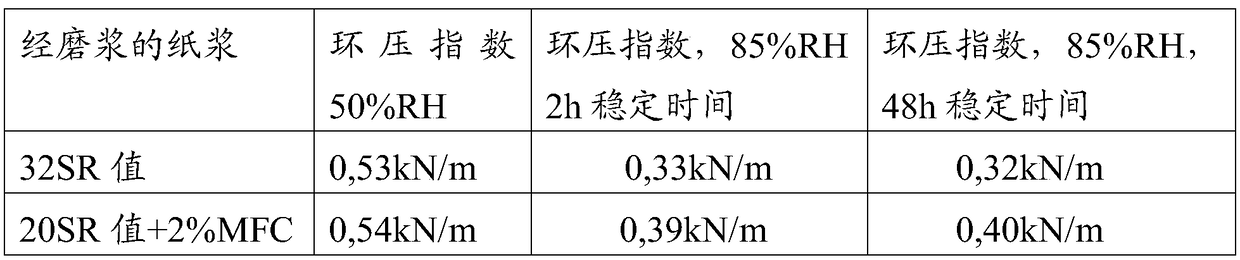

[0080] A pilot paper machine trial was carried out with unbleached kraft pulp having a kappa value of about 72, where an innerliner (simulating the top layer of corrugated board) was produced and typical wet-end chemistry used in the innerliner was used (AKD+Oven treatment, the amount of AKD is 0.02kg / t). The ring pressure index of a conventionally refined virgin fiber with an SR value of 32 was compared with that of a virgin fiber with a reduced refining SR value of 20 added with 2% MFC. The effect on the ring pressure index at higher (85%) relative humidity is shown in Table 2, where the ring pressure index values, especially after a stabilization time of 48 h, were significantly higher than those containing conventionally refined fibers. Paperboard has a high ring pressure index value. The ring pressure index is measured according to ISO 5270.

[0081] Table 2. Effect of less refined fiber and MFC on ring pressure index

[0082]

Embodiment 3

[0084] Moldable product formation tests were carried out using the pulp of Example 2 and 25 kg / t base stock added with microfibrillated cellulose (MFC). The pilot paper machine produced moldable boards and the boards were stored at a moisture content of 85% prior to production of moldable products. The formed moldable product exhibited fewer cracks and defects than a conventionally formed moldable product (without MFC addition and with a higher degree of refining). The results are shown in Table 3.

[0085] table 3

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com