Lead-acid battery tube positive plate grouting method

A lead-acid battery, positive plate technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of harsh working environment, unfavorable battery life, weak bonding strength of active materials, etc. The effect of strong grain structure and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

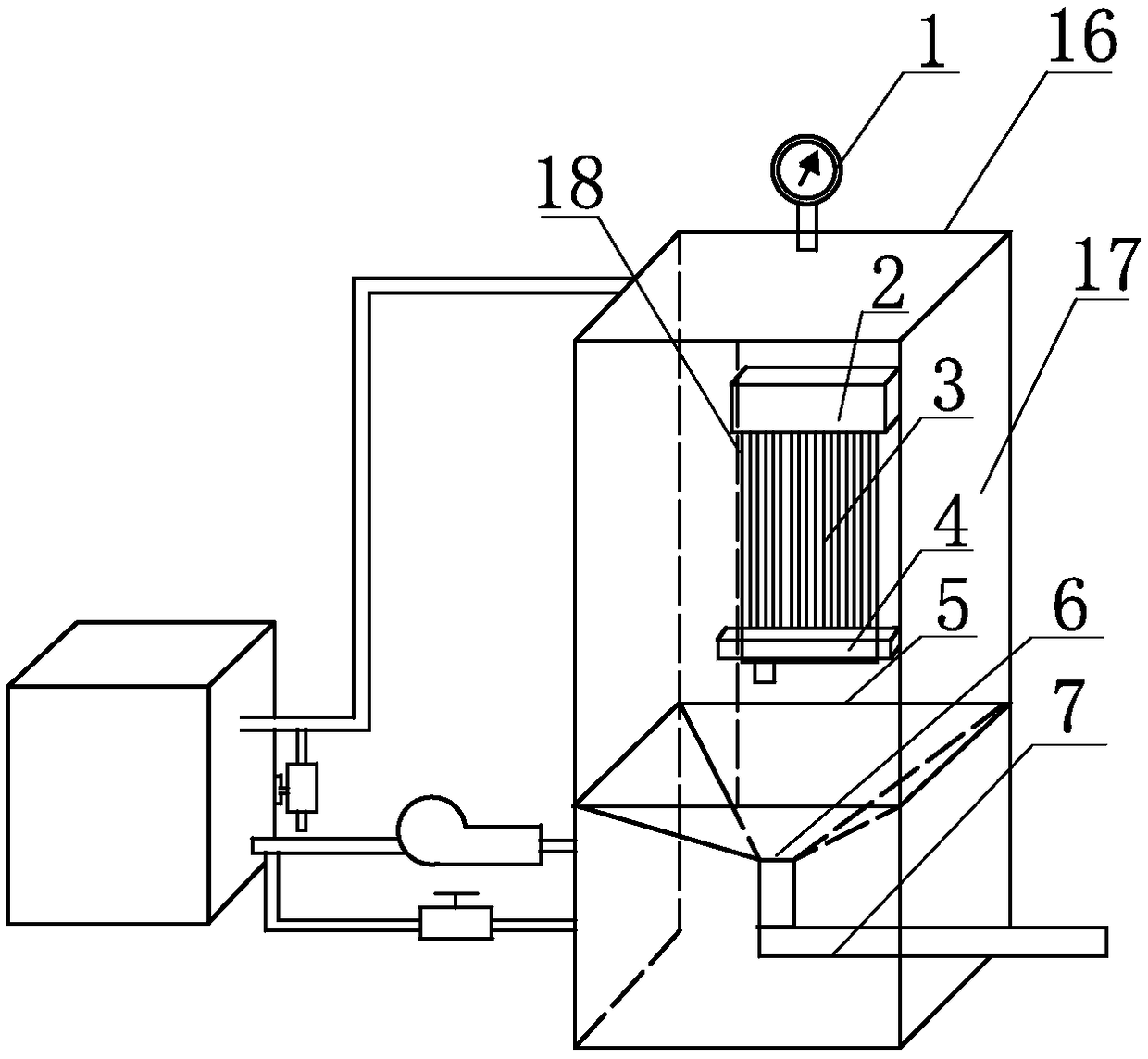

Embodiment 1

[0042] Production of 2V500Ah flooded power lead-acid batteries.

[0043] (1) The shell is made of PP material;

[0044] (2) The partition adopts PE partition;

[0045](3) The positive grid 3 is produced by die-casting a low-antimony five-element alloy, and the mass percentages of the components of the alloy are: 2.8% Sb, 0.12% As, 0.15% Sn, 0.01% Cu, and the balance is Pb;

[0046] (4) The negative grid is produced by gravity casting of low-antimony six-element alloy. The mass percentage of each component of the alloy is: 1.8% Sb, 0.12% As, 0.03% Se, 0.09% Sn, 0.035% Cu, and the balance is Pb;

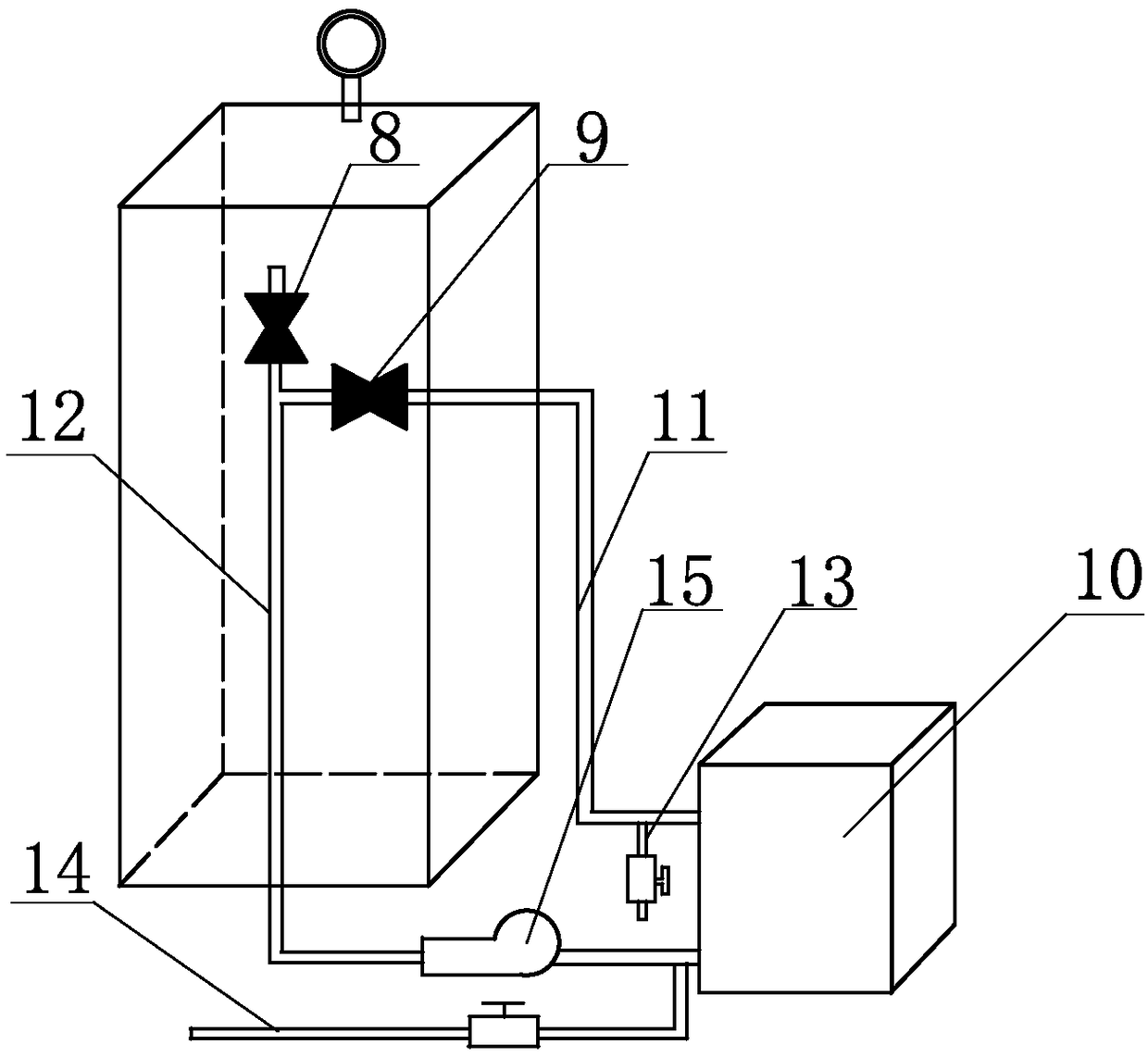

[0047] (5) Preparation of positive lead paste: Add 64kg of Barton lead powder, 36kg of red lead and 0.15kg of polypropylene staple fiber into the paste mixing machine 10, and dry mix for 5 minutes; add 6.9kg of pure water, finish adding within 5 minutes, and stir for 5 minutes; add density 1.400g / cm 3 6kg of sulfuric acid, add it within 15 minutes, stir for 10 minutes; measure the a...

Embodiment 2

[0056] Production of 2V500Ah flooded power lead-acid batteries.

[0057] (1) The shell is made of PP material;

[0058] (2) The partition adopts PE partition;

[0059] (3) The positive grid 3 is produced by die-casting a low-antimony five-element alloy, and the mass percentages of the components of the alloy are: 2.8% Sb, 0.12% As, 0.15% Sn, 0.01% Cu, and the balance is Pb;

[0060] (4) The negative grid is produced by gravity casting of low-antimony six-element alloy. The mass percentage of each component of the alloy is: 1.8% Sb, 0.12% As, 0.03% Se, 0.09% Sn, 0.035% Cu, and the balance is Pb;

[0061] (5) Preparation of positive electrode lead paste: add 70kg Barton lead powder, 30kg red lead, 0.20kg polypropylene staple fiber and 1kg 4BS seed crystal into the paste mixing machine 10, dry mix for 5min; add 7.2kg pure water, finish adding within 5min, Stir for 5min; add density to 1.400g / cm 3 Add 6.2kg of sulfuric acid within 15 minutes, stir for 10 minutes; measure the ap...

Embodiment 3

[0070] Production of 2V500Ah flooded power lead-acid batteries.

[0071] (1) The shell is made of PP material;

[0072] (2) The partition adopts PE partition;

[0073] (3) The positive grid 3 is produced by die-casting a low-antimony five-element alloy, and the mass percentages of the components of the alloy are: 2.8% Sb, 0.12% As, 0.15% Sn, 0.01% Cu, and the balance is Pb;

[0074] (4) The negative grid is produced by gravity casting of low-antimony six-element alloy. The mass percentage of each component of the alloy is: 1.8% Sb, 0.12% As, 0.03% Se, 0.09% Sn, 0.035% Cu, and the balance is Pb;

[0075] (5) Preparation of positive lead paste: Add 66kg of Barton lead powder, 50kg of red lead and 0.10kg of polypropylene staple fiber into the paste mixing machine 10, and dry mix for 5 minutes; add 6.5kg of pure water, finish adding within 5 minutes, and stir for 5 minutes; add density 1.400g / cm 3 Add 6.5kg of sulfuric acid within 15 minutes, stir for 10 minutes; measure the ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com