Hot air recovery up-down alternative heating-drying equipment and method

A technology of alternating heating and drying equipment, applied in lighting and heating equipment, drying, dryers and other directions, can solve problems such as uneven drying effect, avoid uneven drying effect, save energy, and facilitate uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

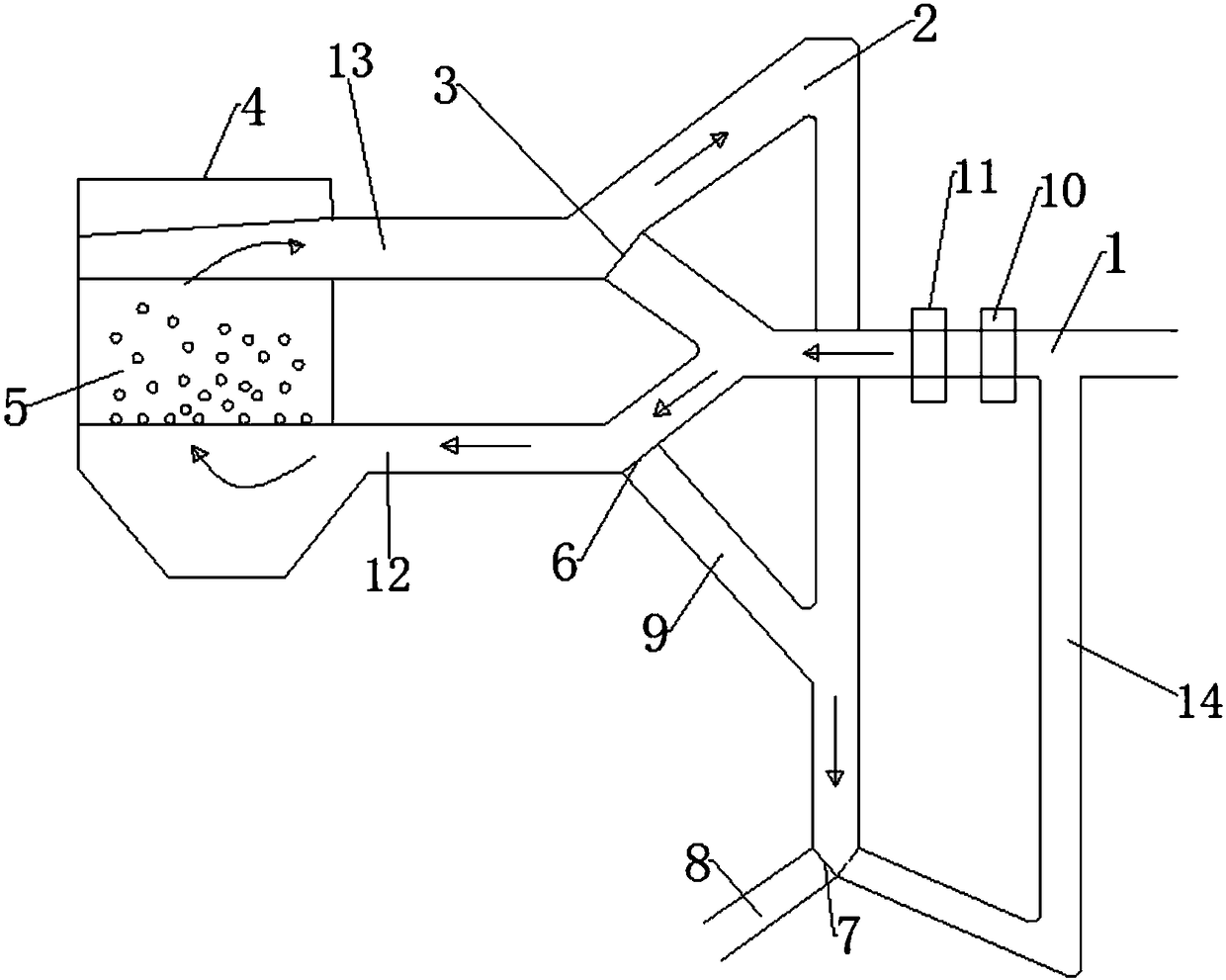

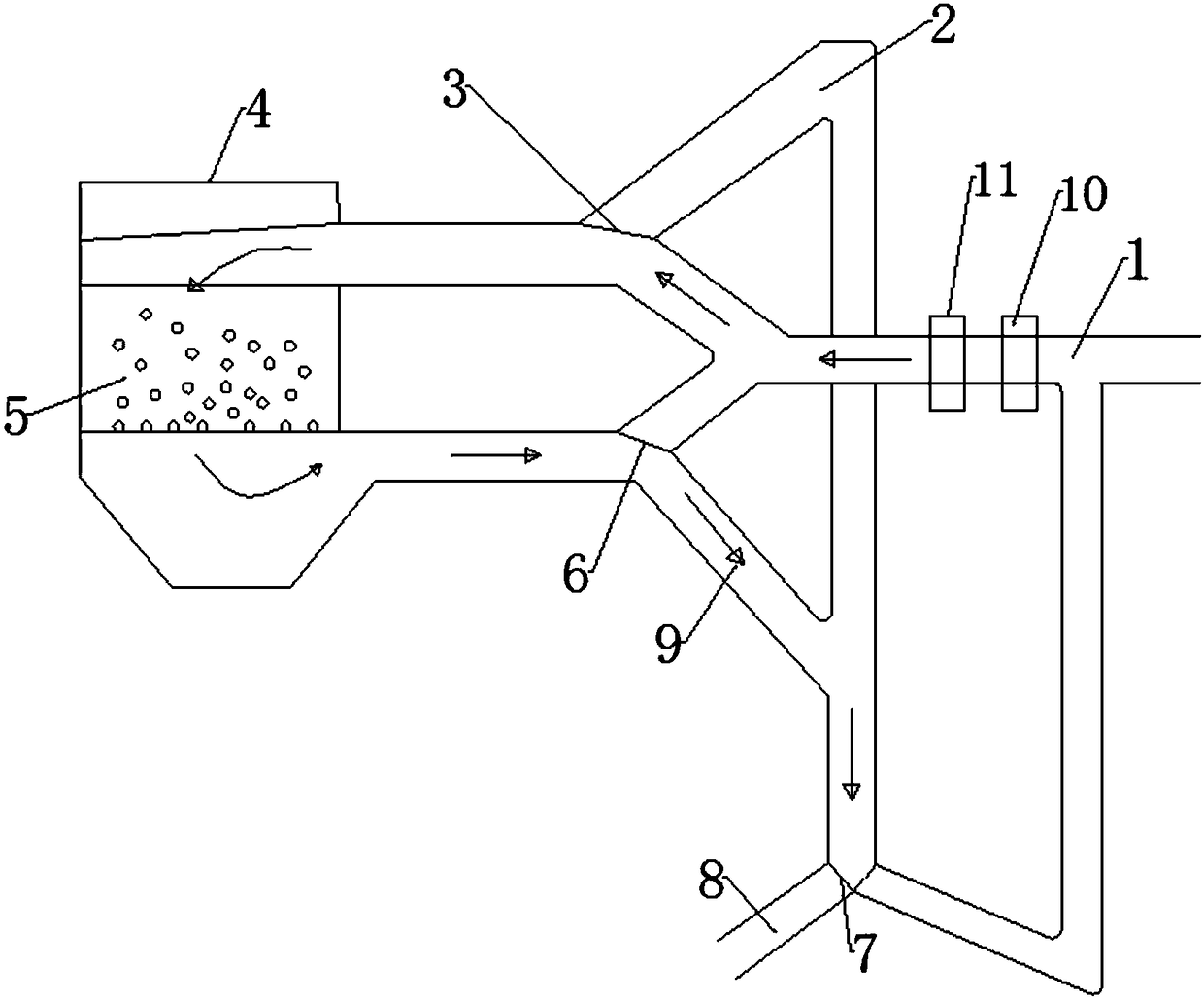

[0051] A hot air recovery method for heating and drying alternately up and down, the steps are as follows:

[0052] 1) Provide the above-mentioned a kind of hot air recycling heating and drying equipment alternately up and down;

[0053] 2) The second valve blocks the fourth pipeline, and at the same time, the first valve blocks the side of the hot air intersection, the hot air enters the hot air intersection from the air inlet pipeline, and enters from the bottom of the drying box through the second pipeline Dry the product to be dried, then flow out through the second pipeline, and then enter the air inlet pipeline through the third pipeline after flowing out;

[0054] 3) The second valve blocks one side of the hot air intersection, and at the same time, the first valve blocks the third pipeline, the hot air enters from the air inlet pipeline to the hot air intersection, and enters from the top of the drying box through the first pipeline Dry the product to be dried, then f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com