Hot air circulation high-temperature heat pump double-drum type dryer

A high-temperature heat pump, double-drum technology, applied in the field of drying, can solve the problems of unevenness, hard adhesion of the drying drum, and difficulty, and achieve the effect of effective drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

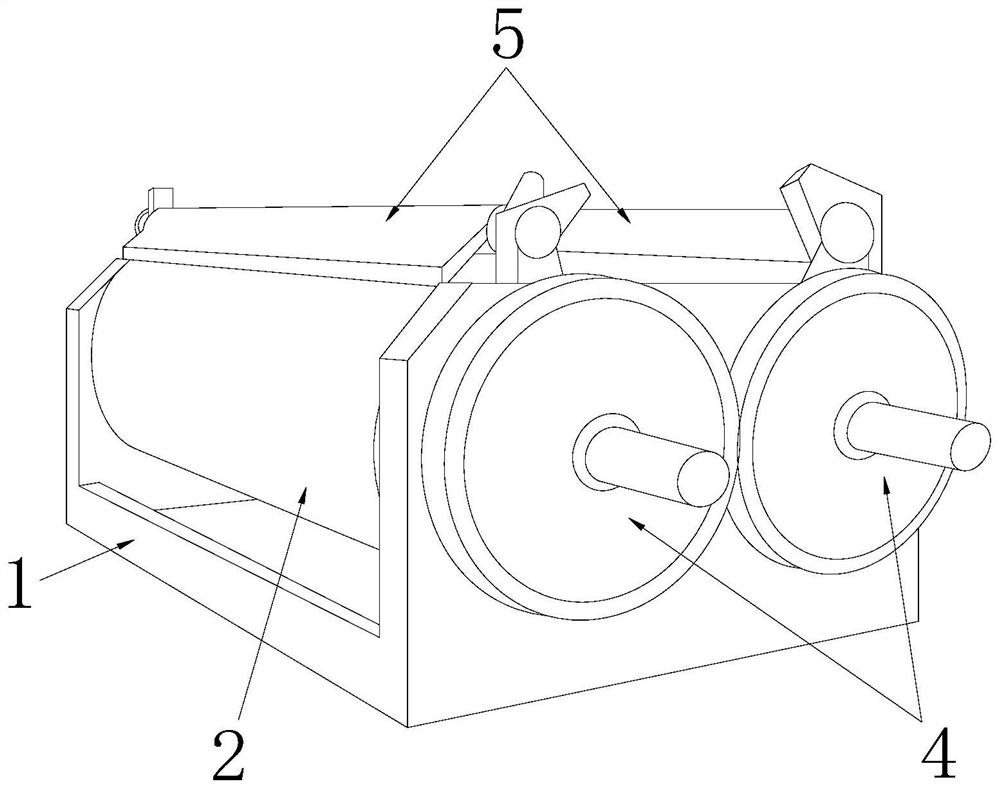

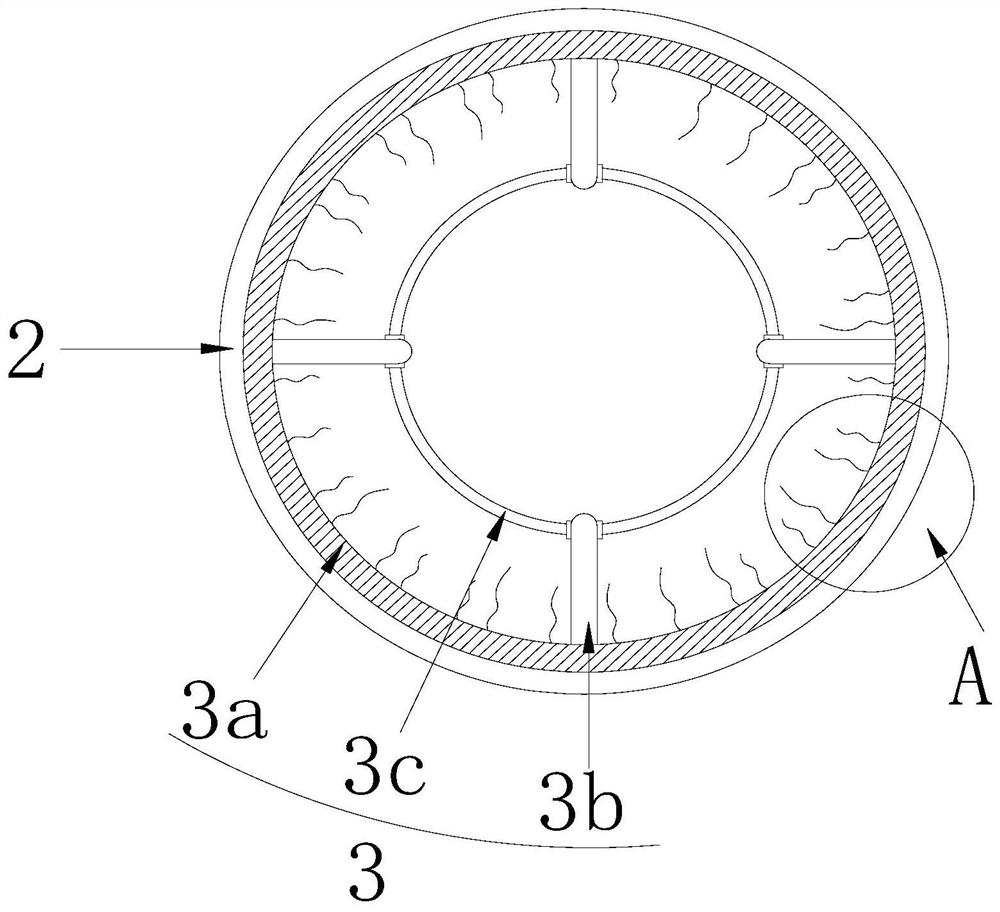

[0028] Such as Figure 1-Figure 3 As shown, the present invention provides a technical solution of a hot air circulation high temperature heat pump double drum dryer:

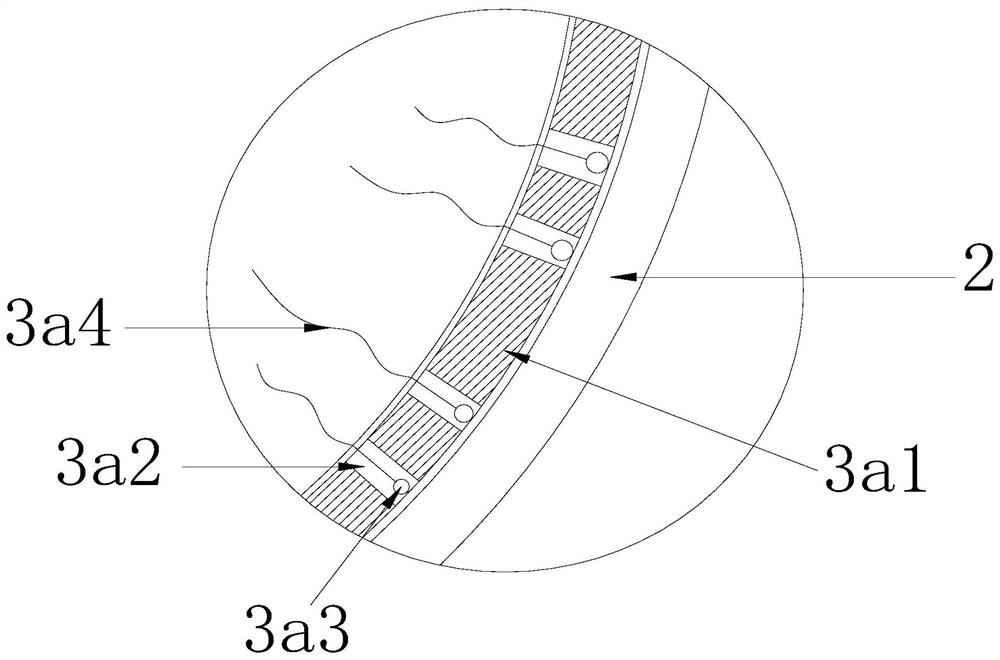

[0029] Such as Figure 1-Figure 2 As shown, a double-drum dryer with hot air circulation and high-temperature heat pump has a structure including a machine base 1, a drying drum 2, a device 3, a drive plate 4, and a heat-conducting pipe 5. The drying drum 2 is provided with two parallel drums. Installed inside the machine base 1, the devices 2 are respectively arranged inside the drying drum 2, the driving discs 4 are respectively located on the right side of the drying drum 2 and cooperate with each other, and the heat-conducting pipes 5 are respectively installed on the drying drum 2 On the surface, the device 3 includes an anti-knot mechanism 3a, an enhanced flow structure 3b, and an connecting plate 3c. The anti-knot mechanism 3a is installed on the inner wall of the drying drum 2. There are four enhanced ...

no. 2 example

[0038] Such as Figure 4-Figure 5 As shown, the present invention provides a technical solution of a hot air circulation high temperature heat pump double drum dryer:

[0039] Such as Figure 4-Figure 5As shown, a hot air circulation high-temperature heat pump double-drum dryer, its structure includes the enhanced flow structure 3b including a positioning tube 3b1, a push rod 3b2, a connecting plate 3b3, a limit bar 3b4, and a bag 3b5, and the push There are two rods 3b2 and the left and right ends are respectively connected through the connecting plate 3b3. The push rod 3b2 is located inside the positioning tube 3b1, and the limit bar 3b4 is provided with two and one end is connected with the connecting plate 3b3. The other end is connected to the lower part of the positioning tube 3b1, and the bladder 3b5 is installed on the upper part of the positioning tube 3b1, which is beneficial to realize that when the drying drum 2 rotates, the push rod 3b2 drives the enhanced flow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com