Diagnostic method for pump station unit based on composite characteristic index and depth limit learning machine

A technology of extreme learning machine and compound features, which is applied in the field of diagnosis of pumping station units based on compound feature indicators and deep extreme learning machines, to achieve the effect of improving accuracy and effectiveness and avoiding limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

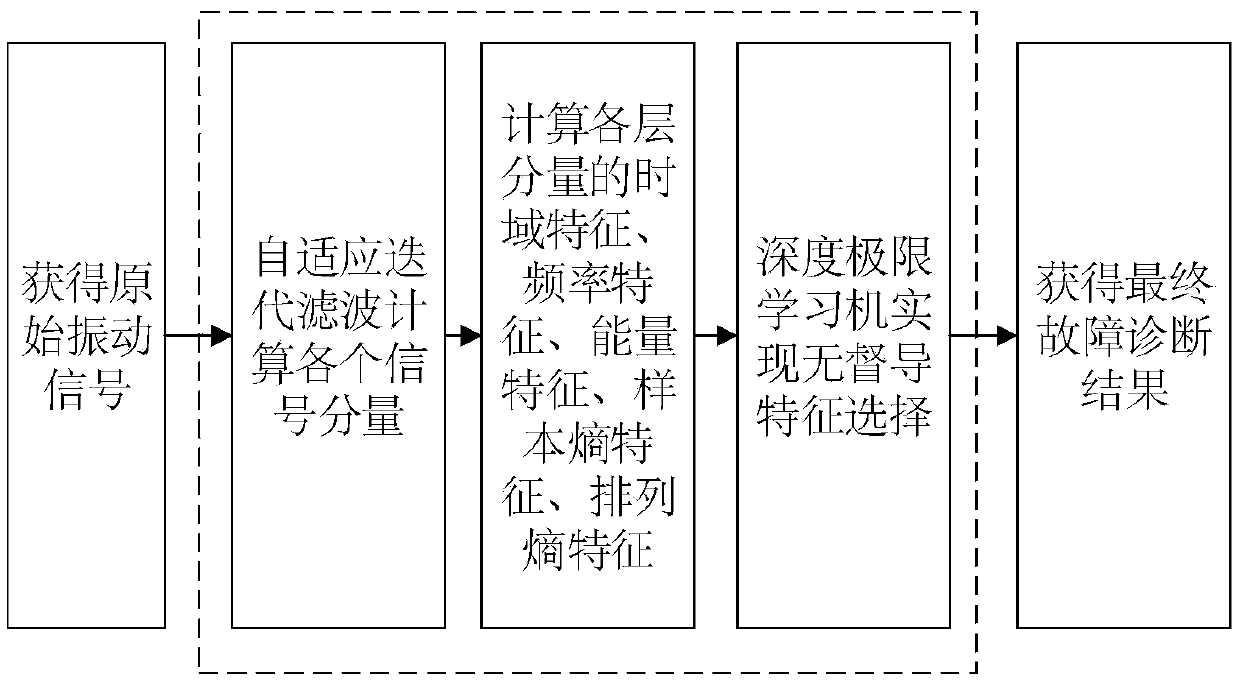

[0063] The pumping station unit diagnosis method provided by the embodiment of the present invention can be implemented by the following methods:

[0064] Step 1. Install sensors such as guide bearing swing, upper frame vibration, lower frame vibration, and casing vibration on the pumping station unit. The swing sensor uses eddy current sensors to collect fault sample data from different parts, that is, unbalanced faults. For misalignment faults, grinding faults, and magnetic pull imbalance faults, add labels to each fault type and establish a training sample set.

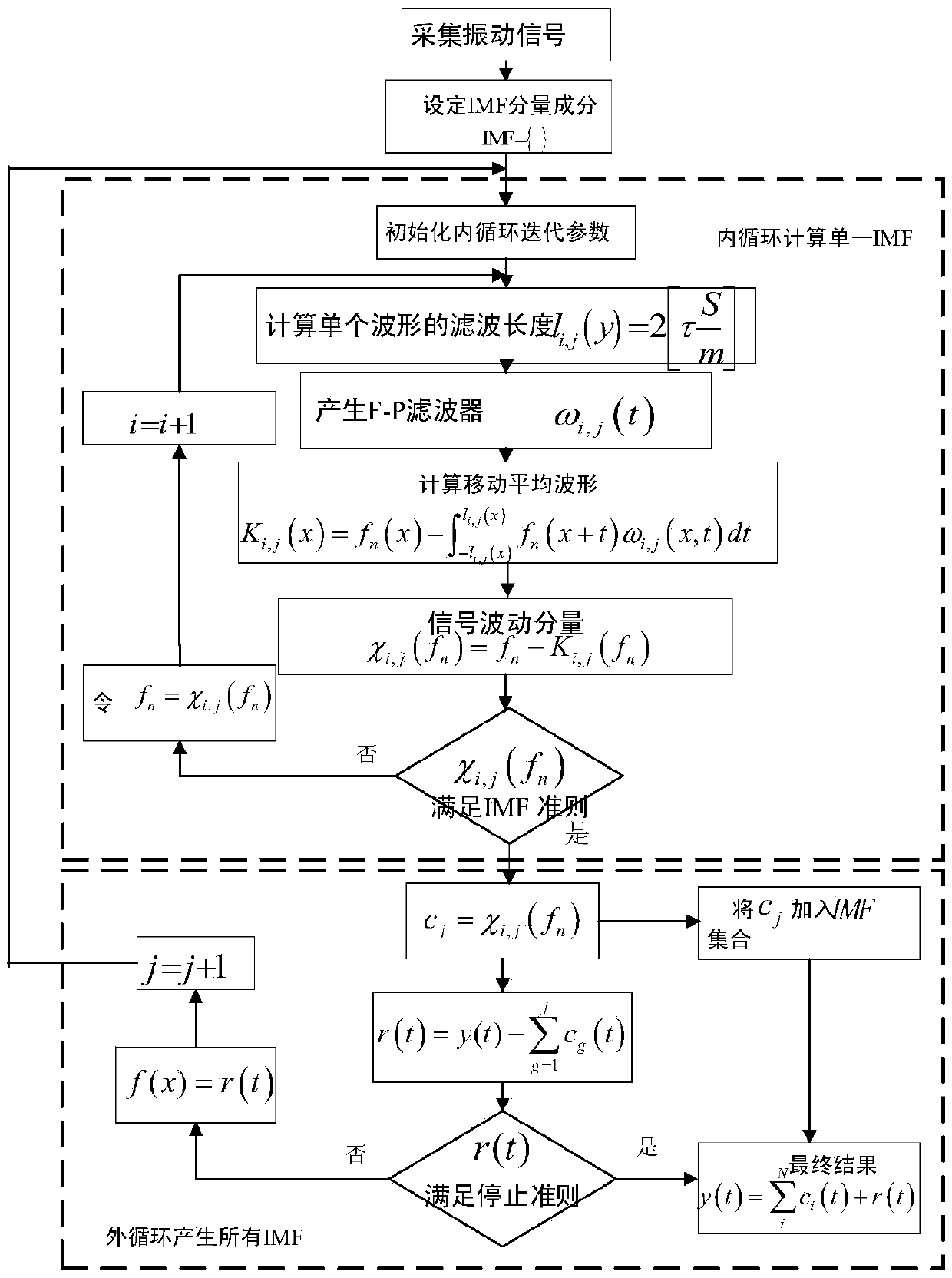

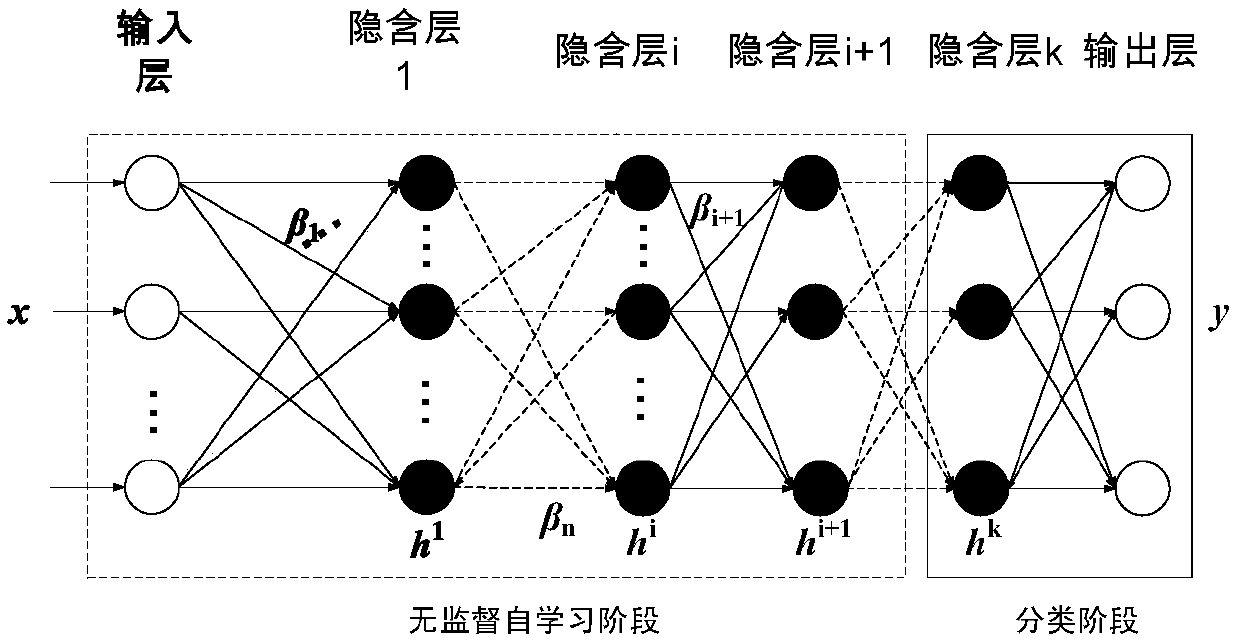

[0065] Step 2. In the feature extraction stage, the signal is substituted into the adaptive iterative filtering algorithm, and the number of IMFs is set according to the on-site waveform conditions, and decomposed to obtain the decomposed component IMF, and the first 95% energy is calculated as the effective component, and the time of each layer is calculated. Domain features, frequency domain features, energy feat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com