Electroplating liquid of trivalent chromium system for ferrochrome electrodeposition and preparation method thereof

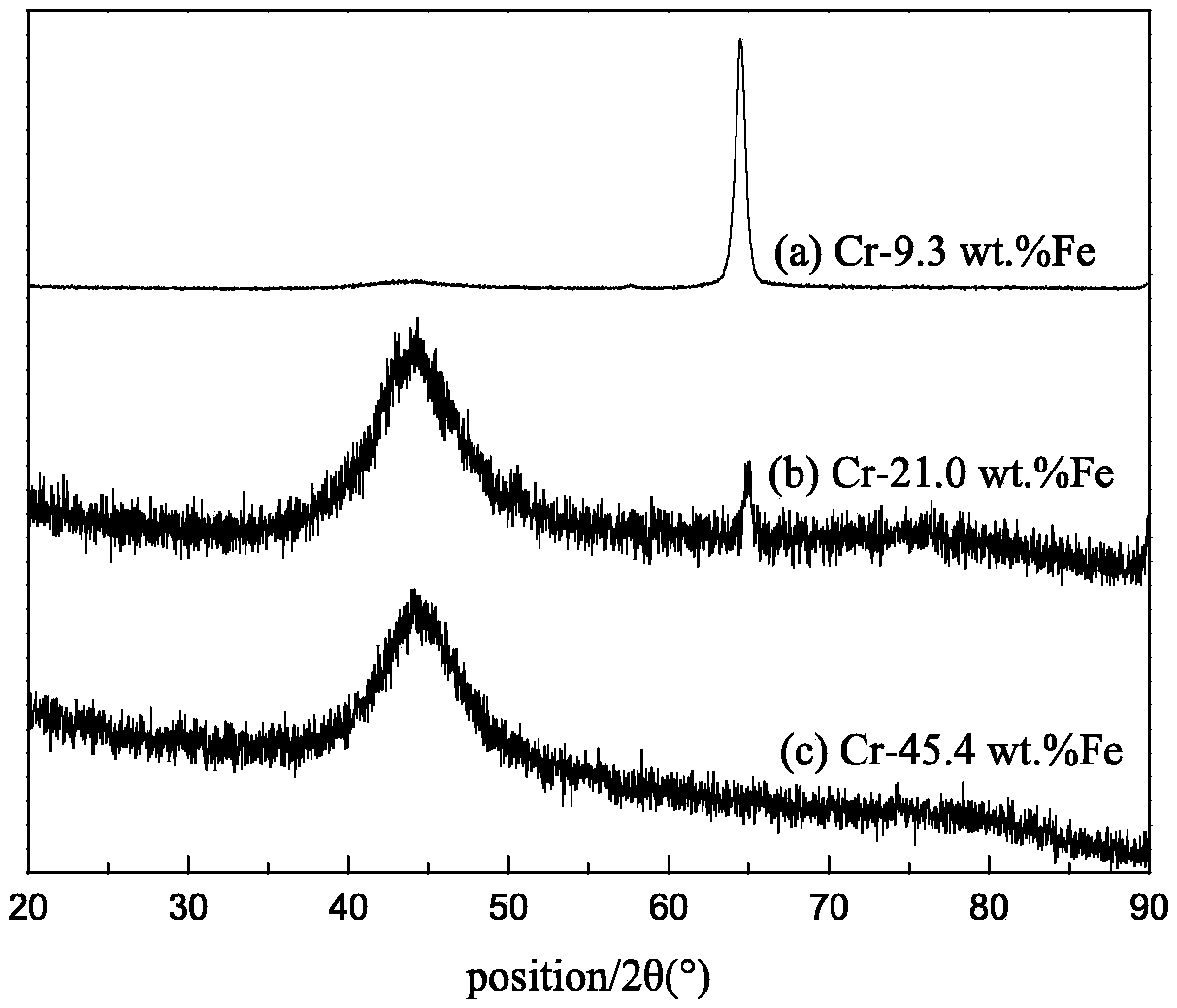

A technology for ferrochrome alloy and trivalent chromium, which is applied in the field of electroplating solution and preparation of ferrochrome alloy electrodeposited by trivalent chromium system, and can solve the problem of large difference in deposition potential of trivalent chromium and ferrous iron complexes and lack of crystal structure of the coating Problems such as controllability, coating structure and iron content are single, to achieve the effect of improving brightness and bright current density range, promoting co-deposition, and improving co-deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

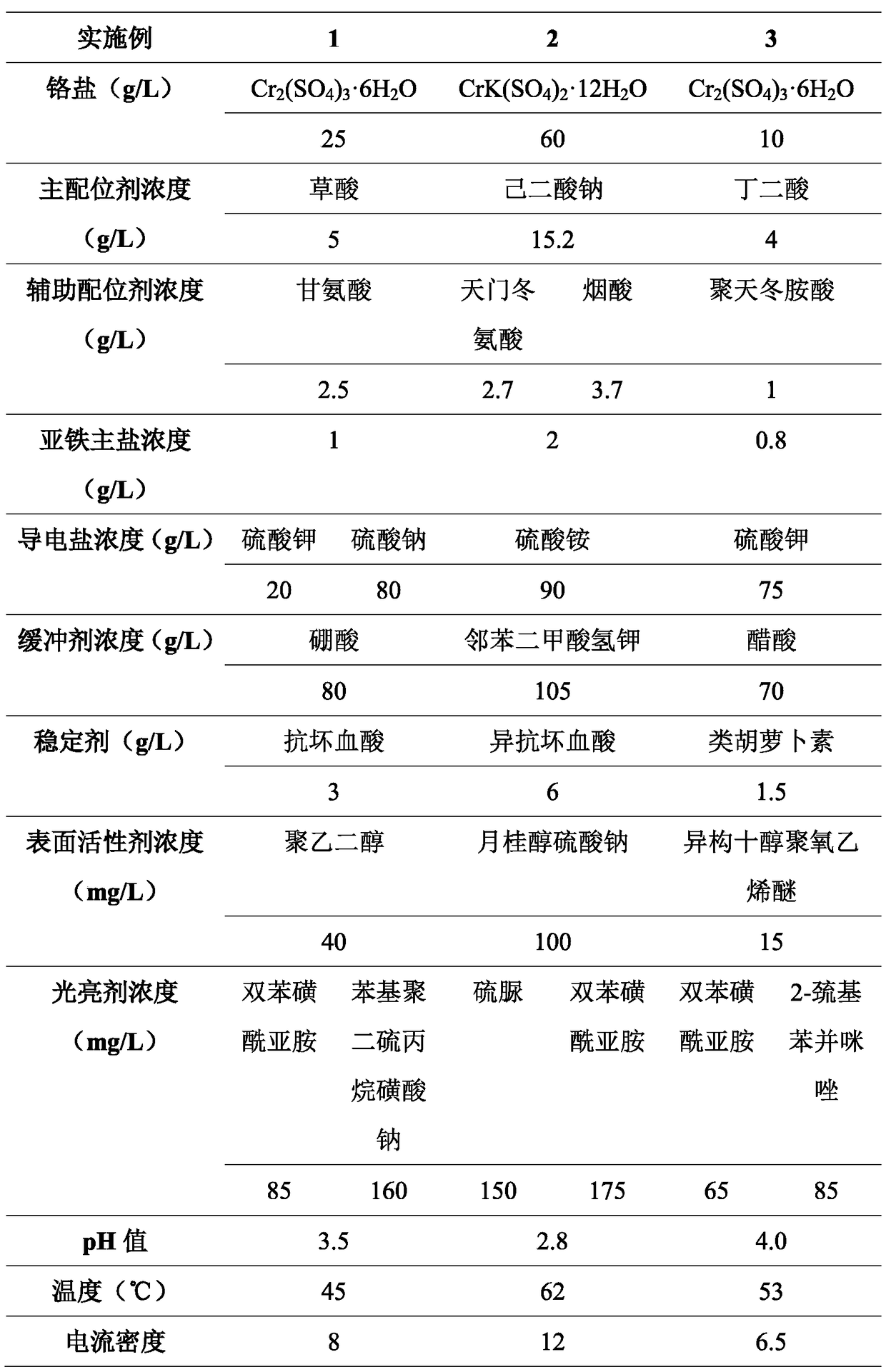

Embodiment 1~3

[0044] The preparation method of the electroplating solution of this embodiment is as follows:

[0045] (1) Add trivalent chromium main salt, trivalent chromium main complexing agent and trivalent chromium auxiliary complexing agent in water, stir to dissolve and keep at 60~65℃ for 1.8~2.5h to obtain the first solution;

[0046] (2) Add the main ferrous salt and stabilizer to the first solution, and stir to dissolve the second solution;

[0047] (3) Add conductive salt and buffer to the second solution, stir and dissolve to obtain the third solution;

[0048] (4) Add surfactant and composite brightener to the third solution, and then add water to the required volume to obtain the fourth solution;

[0049] (5) The electroplating solution is obtained after adjusting the pH of the fourth solution to 2.7-4.5 with sulfuric acid or sodium hydroxide.

[0050] With copper sheet as the base material, the process flow of the electroplating solution prepared above is: ultrasonic degreasing (50~70℃,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com