A cross-linked moisture barrier rubber adhesive, a double-sided adhesive tape using the adhesive and a preparation method thereof

A moisture barrier, double-sided tape technology, applied in adhesive additives, adhesives, polymer adhesive additives, etc., can solve the problem of weak bonding strength, low processing yield, and decreased assembly yield of electronic device modules, etc. problems, to achieve the effect of high bond strength, excellent high temperature and high humidity performance, and good die-cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

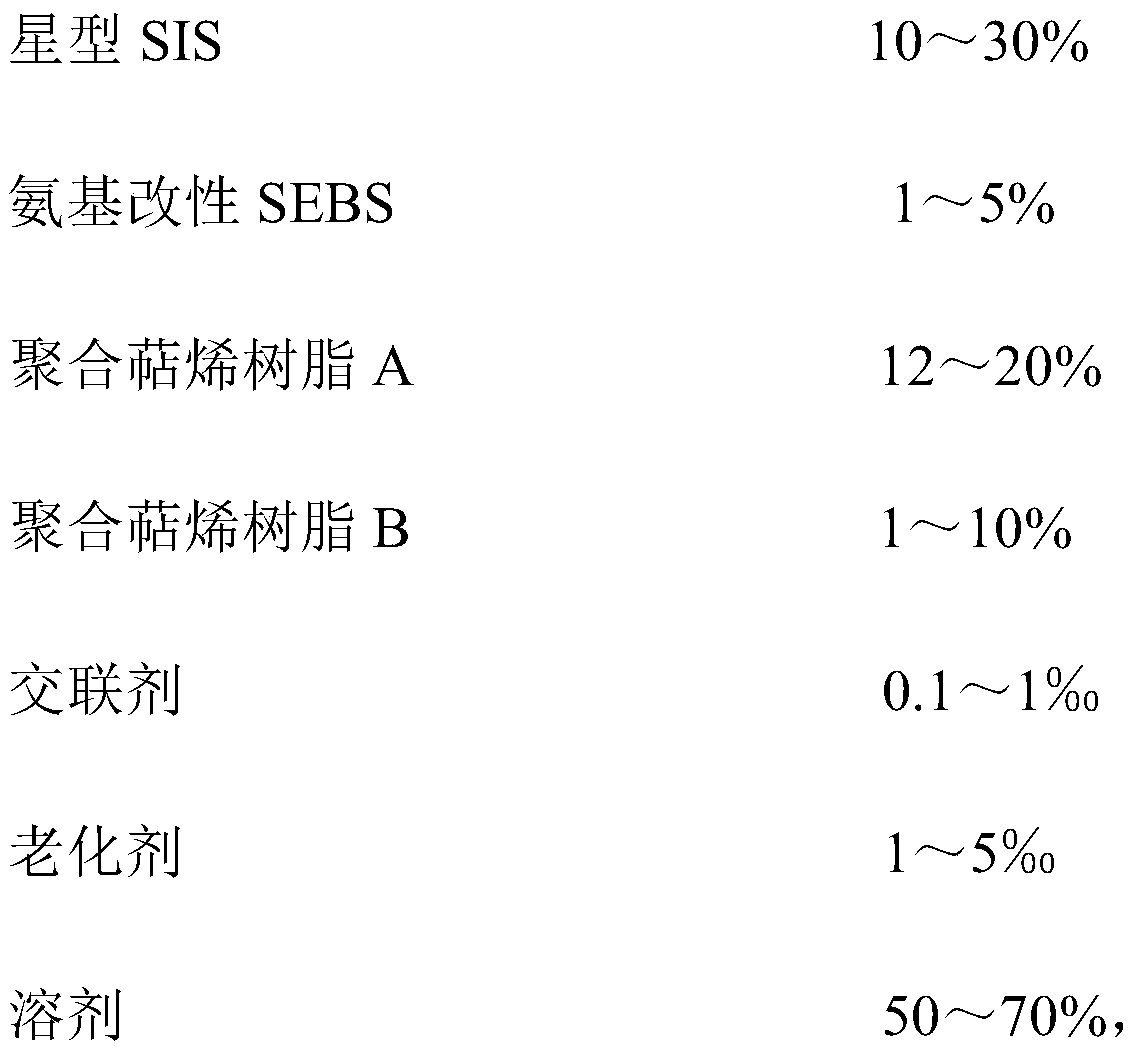

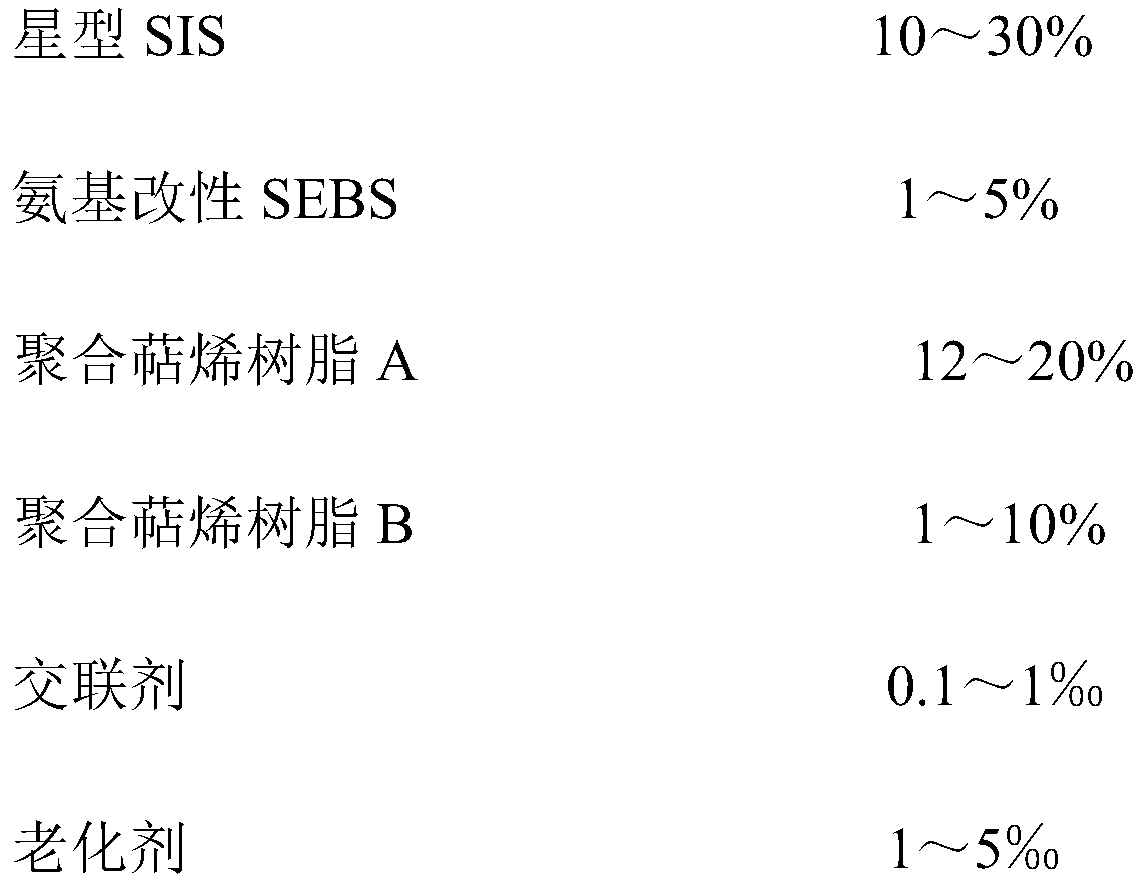

Method used

Image

Examples

Embodiment 1

[0029] The preparation process of the cross-linked moisture barrier rubber adhesive of this embodiment: 330 g of toluene is put into a 1000 ml reaction bottle, and then the stirring device is started at a speed of 200 rpm, and polymerized terpene resin A (softening point of 85°C, melt viscosity of 500mPa·s, molecular weight of 300, glass transition temperature of 50°C) 90g, polymerized terpene resin B (softening point of 30°C, melt viscosity of 50mPa·s, molecular weight of 100, glass Transformation temperature is -50 ℃) 30g, aging agent 1010 and 168 are respectively 0.15g and 0.1g, after stirring for 15min to be dissolved, drop into star-shaped SIS (tensile strength is 1500psi, elongation at break is 800%, 10 The Shore A hardness of the second is 30, and the relative density is 0.89g / cm 3 , the melt index is 6g / 10min, the styrene content is 15%, the diblock content is 0, and the weight average molecular weight is 100,000) 90g, amino-modified SEBS (the tensile strength is 2000p...

Embodiment 2

[0032] The preparation process of the cross-linked moisture barrier rubber adhesive of this embodiment: put 323g of xylene into a 1000ml reaction bottle, then start the stirring device at a speed of 200rpm, and put in the polymerized terpene resin A (softening point is 130°C, melt viscosity is 1500mPa·s, molecular weight is 1500, glass transition temperature is 110°C) 90g, polymerized terpene resin B (softening point is 10°C, melt viscosity is 50mPa·s, molecular weight is 500, Glass transition temperature is -10 ℃) 30g, aging agent 1076 and 168 are respectively 0.15g and 0.1g, after stirring for 15min until it dissolves, put into star-shaped SIS (tensile strength is 3000psi, elongation at break is 1500%, The Shore A hardness of 10 seconds is 60, and the relative density is 0.92g / cm 3, melt index is 18g / 10min, styrene content is 30%, diblock content is 40%, weight average molecular weight is 500,000) 90g, amino-modified SEBS (tensile strength is 2500psi, elongation at break is ...

Embodiment 3

[0035] The preparation process of the cross-linked moisture barrier rubber adhesive of this embodiment: 345 g of cyclohexanone was put into a 1000 ml reaction bottle, and then the stirring device was started at a speed of 200 rpm, and polymerized terpene resin A (softened point is 100°C, melt viscosity is 1000mPa·s, molecular weight is 1000, glass transition temperature is 100°C) 90g, polymerized terpene resin B (softening point is 10°C, melt viscosity is 25mPa·s, molecular weight is 400 , glass transition temperature is -20℃) 30g, aging agent 2,6-di-tert-butyl-p-cresol and 168 respectively 0.15g and 0.1g, stir for 15min until it dissolves, then put into star SIS (tensile strength It is 2000psi, the elongation at break is 1000%, the Shore A hardness of 10 seconds is 50, and the relative density is 0.90g / cm 3 , melt index is 10g / 10min, styrene content is 20%, diblock content is 20%, weight average molecular weight is 200,000) 90g, amino-modified SEBS (tensile strength is 2000ps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com