A kind of preparation method and application of pentaerythritol methylphenylthiosilicate

A technology of pentaerythritol silicate and methyl phenyl thio group, which is applied in the chemical field, can solve the problem that the flame retardant performance cannot meet the production requirements, etc., and achieves the effects of meeting the requirements of flame retardancy, improving the flame retardancy and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

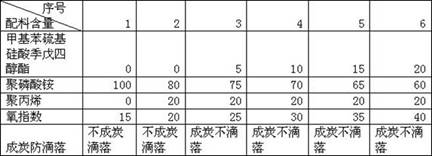

Examples

Embodiment 1

[0017] Preparation of intermediate: In a 100mL three-necked round-bottomed flask equipped with a stirrer, thermometer, dropping funnel, reflux condenser and hydrogen chloride absorption device, add 50mL of diethylene glycol dimethyl ether as a solvent and 0.1mol (13.62g) For pentaerythritol, add 0.1mol (14.95g) methyltrichlorosilane dropwise under stirring in an ice-water bath, and control the reaction temperature of the system not higher than 50°C. Reaction at 140°C for 4h. After no hydrogen chloride gas is released, most of the diethylene glycol dimethyl ether is distilled off under reduced pressure to obtain a white viscous liquid, which is cooled and crystallized, filtered, washed with dichloroethane, and dried to obtain a white solid formazan pentaerythritol silicate (CSRC).

[0018] Preparation of sodium benzenethiol: at room temperature, add 0.1mol (11.0g) of benzenethiol to an anhydrous and dry Erlenmeyer flask, then add 0.1mol (2.3g) of sodium particles, and shake sl...

Embodiment 2

[0021] Preparation of intermediate: In a 100mL three-necked round-bottomed flask equipped with a stirrer, thermometer, dropping funnel, reflux condenser and hydrogen chloride absorption device, add 50mL of diethylene glycol dimethyl ether as a solvent and 0.1mol (13.62g) For pentaerythritol, add 0.1mol (14.95g) methyltrichlorosilane drop by drop under stirring in an ice-water bath, control the reaction temperature of the system not higher than 50°C, slowly raise the temperature to 65°C after dropping, keep warm for 1.5h , heated to 150 ° C for 4.5 h. After no hydrogen chloride gas is released, most of the diethylene glycol dimethyl ether is distilled off under reduced pressure to obtain a white viscous liquid, which is cooled and crystallized, filtered, washed with dichloroethane, and dried to obtain a white solid formazan pentaerythritol silicate (CSRC).

[0022] Preparation of sodium benzenethiol: at room temperature, add 0.1mol (11.0g) of benzenethiol to an anhydrous and d...

Embodiment 3

[0025] Preparation of intermediate: In a 100mL three-necked round-bottomed flask equipped with a stirrer, thermometer, dropping funnel, reflux condenser and hydrogen chloride absorption device, add 50mL of diethylene glycol dimethyl ether as a solvent and 0.1mol (13.62g) For pentaerythritol, add 0.1mol (14.95g) methyltrichlorosilane drop by drop under stirring in an ice-water bath. Reaction at 160°C for 5h. After no hydrogen chloride gas is released, most of the diethylene glycol dimethyl ether is distilled off under reduced pressure to obtain a white viscous liquid, which is cooled and crystallized, filtered, washed with dichloroethane, and dried to obtain a white solid formazan pentaerythritol silicate (CSRC).

[0026] Preparation of sodium benzenethiol: at room temperature, add 0.1mol (11.0g) of benzenethiol to an anhydrous and dry Erlenmeyer flask, then add 0.1mol (2.3g) of sodium particles, and shake slowly until there are no bubbles Generate, stand still.

[0027] Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com