A method of controlling fused silica static acid etch deposits

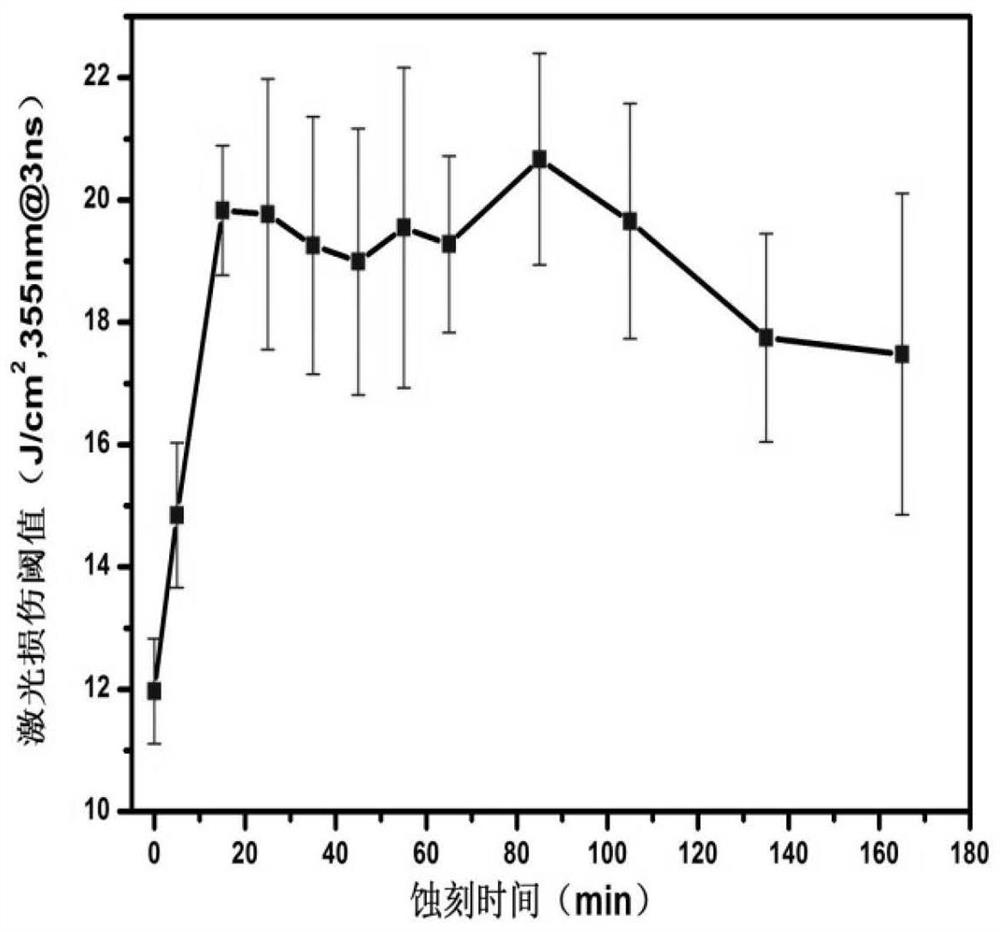

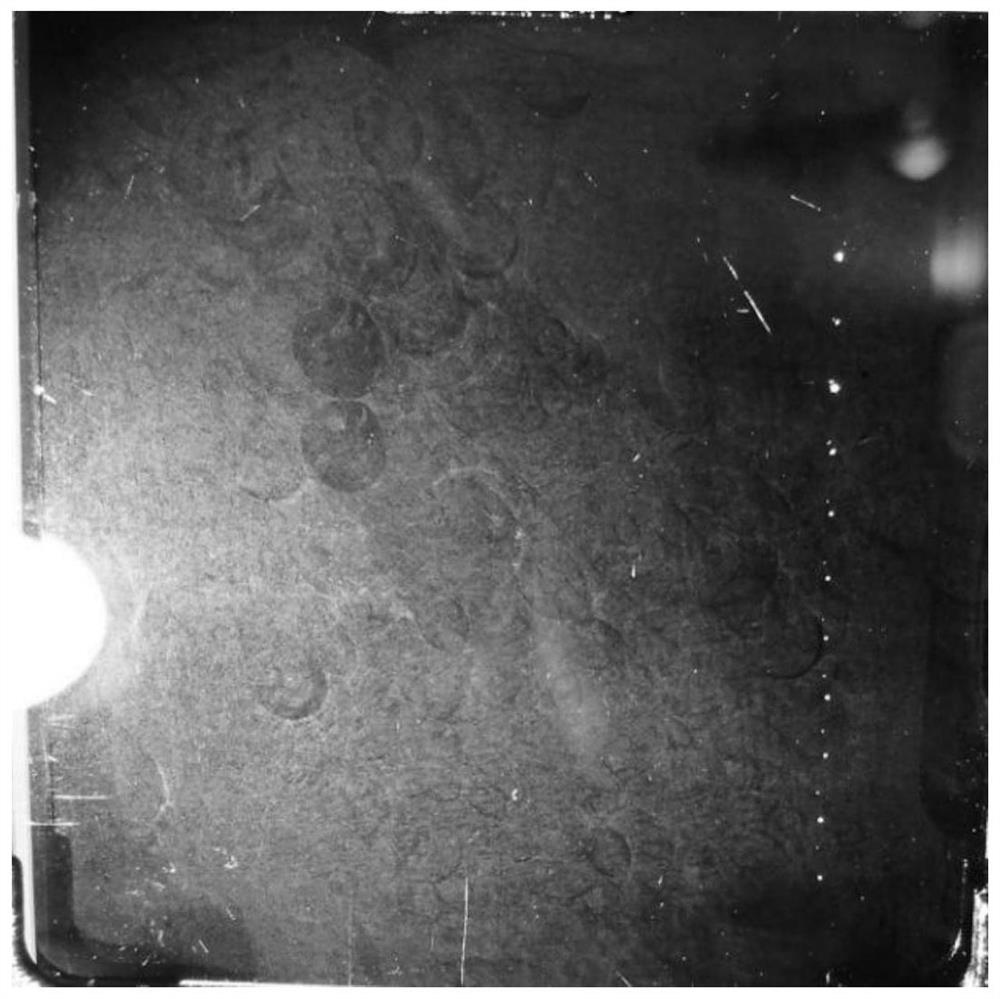

A technology of fused silica and acid etching, which is applied in the field of controlling fused silica static acid etching deposits, can solve the problems of components failing to reach the optical index, threshold drop surface deposits, uneven etching, etc., without destroying the surface shape and roughness degree, improve the laser damage threshold, and avoid the effects of deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method of controlling fused silica static acid etching deposits, comprising the steps of:

[0035] Step 1. Put 50mm×50mm×5mm fused silica into the buffered hydrofluoric acid etching solution, the temperature is 23°C, the etching time for a single reaction is 15min, and the average etching rate is 1.5μm / h;

[0036] Step 2. Spray and rinse the fused silica etched in step 1 with high-purity water. The spray pressure is 0.5Mpa, the temperature is 30°C, the flow rate is 120L / min, and the time is 15min, to remove excess acid and a large amount of SiF on the surface. 6 2- ;

[0037] Step 3. Put the fused silica rinsed in step 2 into a tank filled with high-purity water for ultrasonic rinsing at a temperature of 35°C, ultrasonic power density of 10W / L, 220KHz ultrasonic cleaning for 20min, and 270KHz for 20min to further remove SiF 6 2- ion;

[0038] Step 4. Put the fused silica after rinsing in Step 3 into a tank filled with high-purity water, the temperature is 55°C, th...

Embodiment 2

[0043] A method of controlling fused silica static acid etching deposits, comprising the steps of:

[0044] Step 1. Put 50mm×50mm×5mm fused silica into the buffered hydrofluoric acid etching solution, the temperature is 24°C, the etching time for a single reaction is 20min, and the average etching rate is 2μm / h;

[0045] Step 2. Spray and rinse the fused silica etched in step 1 with high-purity water. The spray pressure is 0.6Mpa, the temperature is 32°C, the flow rate is 120L / min, and the time is 20min, to remove excess acid and a large amount of SiF on the surface. 6 2- ;

[0046] Step 3. Put the fused quartz rinsed in Step 2 into a tank filled with high-purity water for ultrasonic rinsing at a temperature of 35°C, with an ultrasonic power density of 10W / L, 220KHz ultrasonic cleaning for 25min, and 270KHz cleaning for 25min to further remove SiF 6 2- ion;

[0047] Step 4. Put the fused silica after rinsing in Step 3 into a tank filled with high-purity water, the temperat...

Embodiment 3

[0052] A method of controlling fused silica static acid etching deposits, comprising the steps of:

[0053] Step 1. Put the fused silica of 430mm×430mm×20mm into the buffered hydrofluoric acid etching solution, the temperature is 24°C, the etching time for a single reaction is 20min, and the average etching rate is 1.8μm / h;

[0054] Step 2. Spray and rinse the fused silica etched in step 1 with high-purity water. The spray pressure is 0.6Mpa, the temperature is 32°C, the flow rate is 120L / min, and the time is 18min, to remove excess acid and a large amount of SiF on the surface. 6 2- ;

[0055] Step 3. Put the fused silica rinsed in step 2 into a tank filled with high-purity water for ultrasonic rinsing at a temperature of 35°C, with an ultrasonic power density of 12W / L, 220KHz ultrasonic cleaning for 25min, and 270KHz for 20min to further remove SiF 6 2- ion;

[0056] Step 4. Put the fused quartz rinsed in Step 3 into a tank filled with high-purity water at a temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com