Vanadium tetrasulfide electrode material and preparation method and application thereof

A technology of vanadium tetrasulfide, electrode material, applied in chemical instruments and methods, negative electrodes, nanotechnology for materials and surface science, etc. Discharge performance and cycle performance, etc., to achieve the effect of simple process and strong implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of vanadium tetrasulfide electrode material, comprises the following steps:

[0031] a) mixing vanadium source, sulfur source and surfactant in a solvent to obtain a mixed solution; said surfactant is selected from polyvinylpyrrolidone, sodium dodecylbenzenesulfonate and cetyltrimethyl bromide One or more of ammonium chloride;

[0032] b) subjecting the mixed solution obtained in step a) to a solvothermal reaction, collecting solid products, washing and drying in sequence to obtain a vanadium tetrasulfide electrode material.

[0033] In the invention, the vanadium source, the sulfur source and the surfactant are firstly mixed in a solvent to obtain a mixed solution. In the present invention, the vanadium source is preferably selected from one or more of iron vanadate, indium vanadate, bismuth vanadate, silver vanadate, sodium metavanadate and sodium orthovanadate, more preferably iron vanadate , silver vanadate, sodi...

Embodiment 1

[0065] (1) Weigh 1.21g of sodium metavanadate into 60mL of ethanol and stir for 2h; weigh 2.89g of thiourea and 1.95g of sodium dodecylbenzenesulfonate into 20mL of methanol and stir for 3h; mix and stir the two solutions 0.5h, to obtain a uniform mixed solution;

[0066] (2) Put the mixed solution obtained in step (1) into a 100mL reactor for solvothermal reaction. The parameters of the solvothermal reaction are set as follows: the temperature is 100°C, and the time is 15h; method to collect the black powder obtained by the reaction, wash it several times and dry it to obtain VS 4 electrode material.

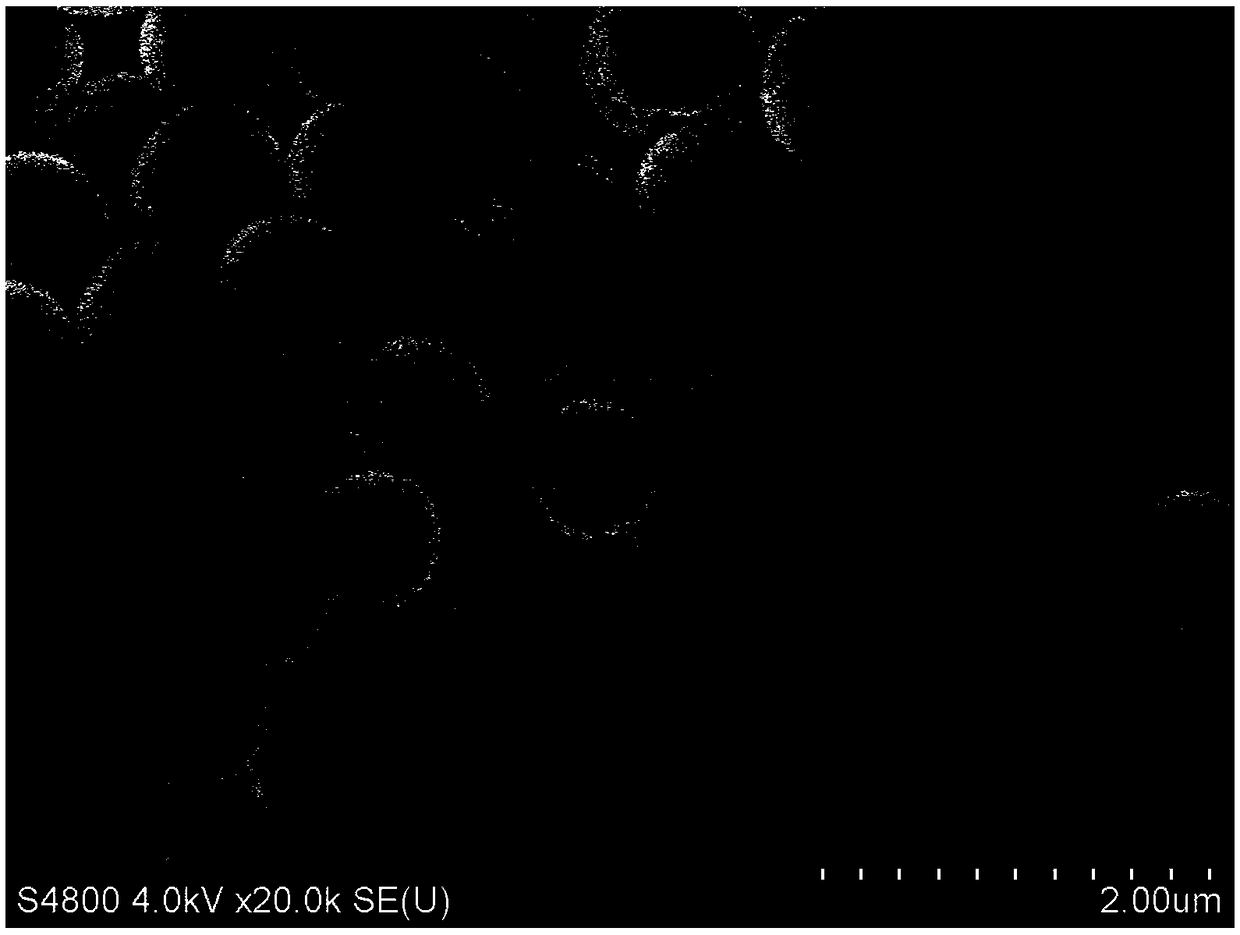

[0067] After testing, the VS provided by Example 1 of the present invention 4 The shape of the electrode material is nano-flaky hollow sphere with a diameter of about 8 μm and an inner diameter of 6 μm. The thickness of the shell is about 900 nm, and the thickness of the surface sheet of the spherical shell is about 60 nm. The specific SEM image is as follows figure 1 shown....

Embodiment 2

[0072] (1) Weigh 1.03g sodium orthovanadate and add it to 10mL ethanol, stir for 2h; weigh 3.97g thiourea and 1.85g hexadecyltrimethylammonium bromide, add it to 75mL methanol and stir for 3h; mix the two solutions Mix and stir for 0.5h to obtain a uniform mixed solution;

[0073] (2) Put the mixed solution obtained in step (1) into a 100mL reactor for solvothermal reaction. The parameters of the solvothermal reaction are set as follows: the temperature is 140°C, and the time is 15h; method to collect the black powder obtained by the reaction, wash it several times and dry it to obtain VS 4 electrode material.

[0074] After testing, the VS provided by Example 2 of the present invention 4The shape of the electrode material is a nano-sheet-shaped hollow sphere with a diameter of about 7 μm and an inner diameter of 5 μm. The thickness of the shell is about 900 nm, and the thickness of the surface sheet of the spherical shell is about 50 nm.

[0075] Battery assembly and testi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com