Preparation method of nano-diamond colloid and nano-diamond secondary dispersion method

A nano-diamond and secondary dispersion technology, which is applied in the field of nano-diamond secondary dispersion and nano-diamond colloid preparation, can solve the problems that have not mentioned the nano-diamond secondary dispersion, so as to achieve easy realization of large-scale production, enhanced practicability, Handle simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

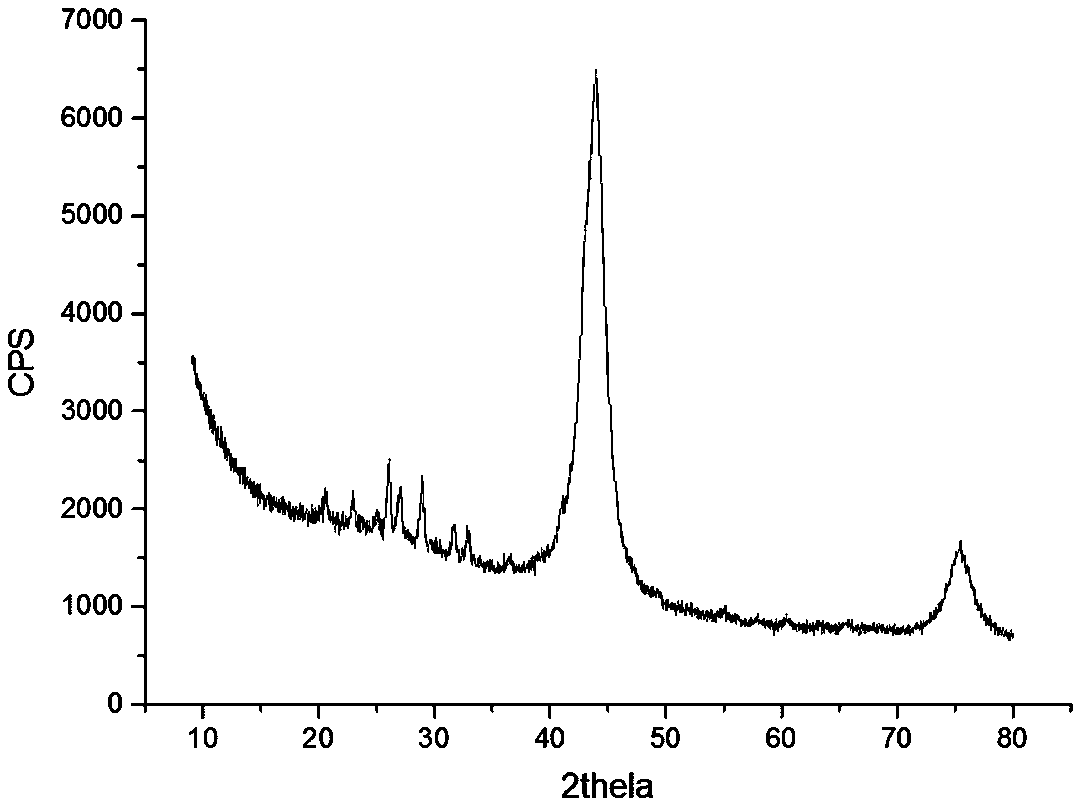

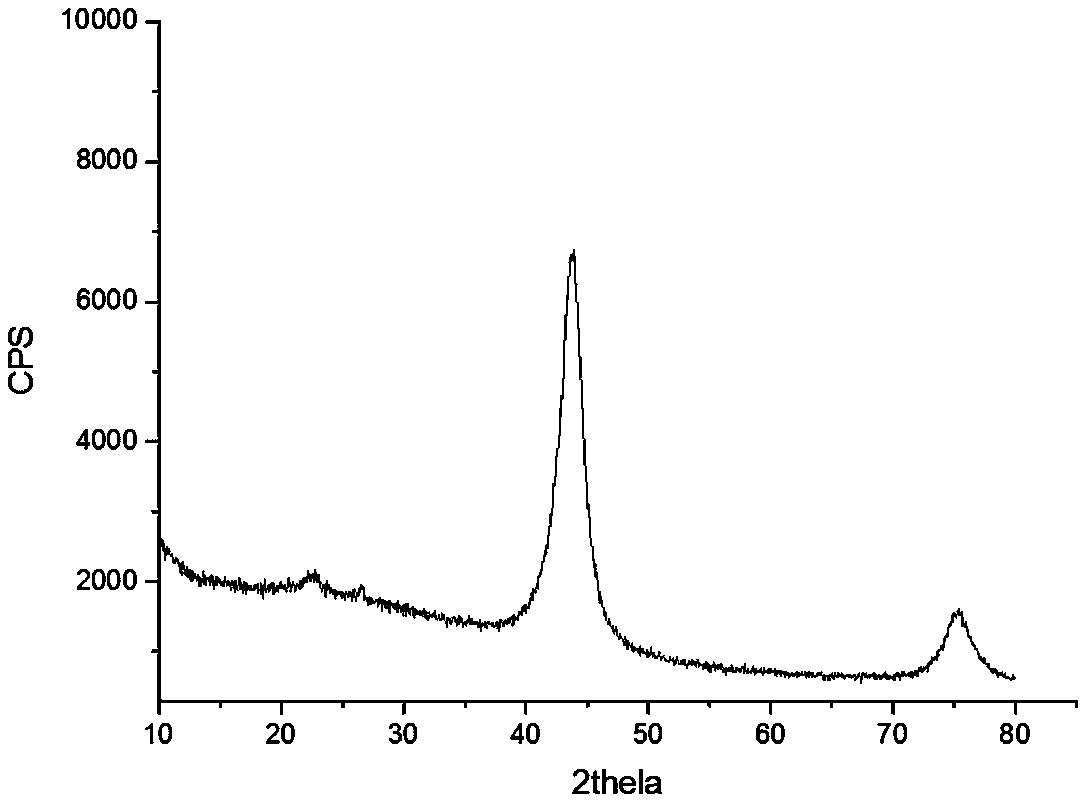

[0034] a. Add 2g of nano-diamond raw material obtained by detonation method (from Hebei Satellite Chemical Co., Ltd.) into a high-temperature reactor, and add 40mL of concentrated HN0 3 React at 200°C for 4 hours. After the reaction, the nano-diamonds are taken out and washed repeatedly with deionized water until neutral to obtain acidified nano-diamonds. X-ray diffraction tests were carried out on nano-diamond raw materials and acidified nano-diamonds respectively, and the results are as follows: figure 1 and figure 2 As shown, it can be seen from the figure that compared with the nano-diamond raw material, the graphite and amorphous carbon content in the acidified nano-diamond is reduced.

[0035] b. Take 400g of ball milling / grinding beads with a diameter of 0.08-0.1mm (the " / " here means "or", the same below) into a ball milling / grinding jar with a volume of 100mL, and then add 0.5g of acidification treatment After the nano-diamond and 50 g n-octane, 0.5 g oleic acid, ...

Embodiment 2

[0039] a. Add the nano-diamond raw material obtained by 2g detonation method into the high-temperature reaction kettle, and add 40mL concentrated HN0 3, reacted at 200°C for 4h, and after the reaction, the nano-diamonds were taken out and washed repeatedly with deionized water until neutral to obtain acidified nano-diamonds.

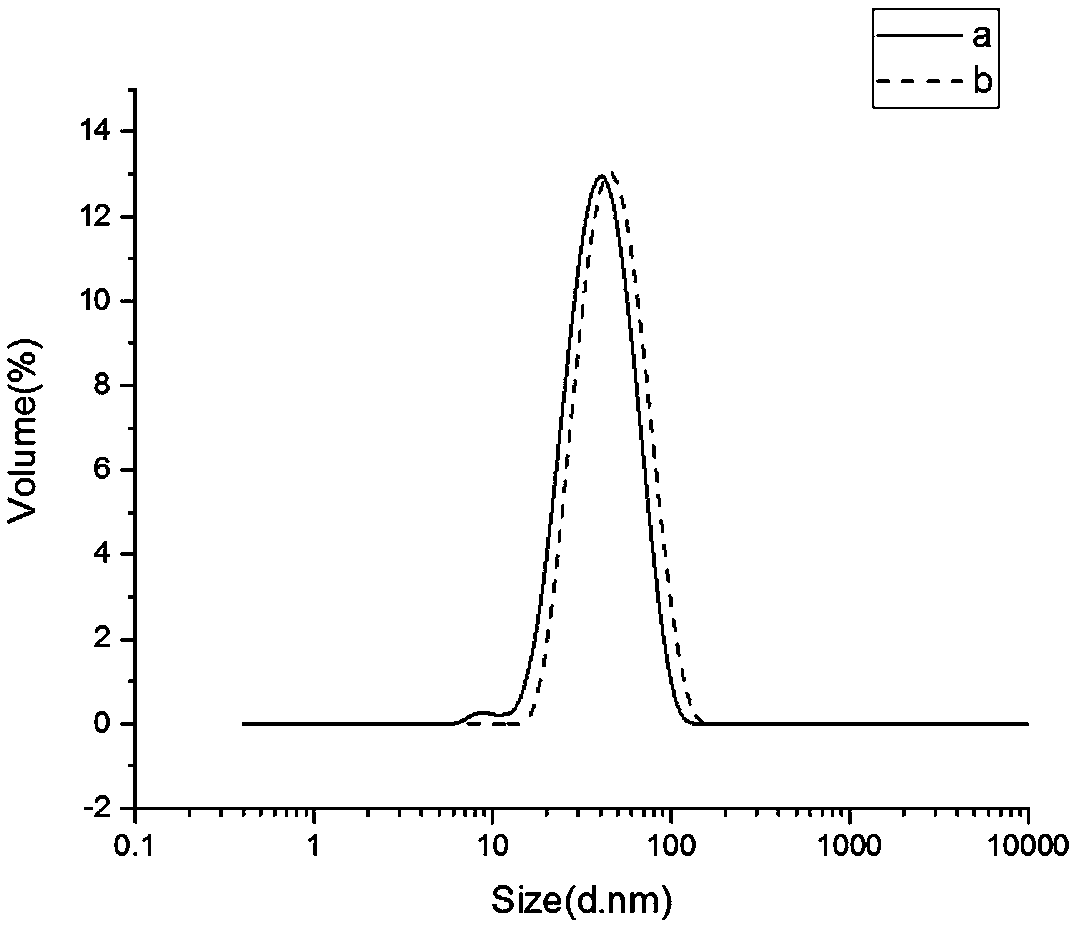

[0040] b. Take 400g of ball milling / grinding beads with a diameter of 0.08-0.1mm and put them into a ball milling / grinding jar with a volume of 100mL, add 0.5g of acidified nano-diamond, 50g of n-octane, 0.5g of oleic acid, set The rotating speed of the ball mill / mill is 580r / min, the ball mill / grinding time is 4h, and a clear and transparent black colloidal solution is obtained, which is characterized by dynamic light scattering, and the obtained results are as follows Figure 4 Shown in curve a.

[0041] c. Use a rotary evaporator to remove excess n-octane solvent from the obtained clear and transparent nano-diamond black colloid solution, set the tem...

Embodiment 3

[0044] a. Add the nano-diamond raw material obtained by 2g detonation method into the high-temperature reaction kettle, and add 40mL concentrated HN0 3 React at 200°C for 4 hours. After the reaction, the nano-diamonds are taken out and washed repeatedly with deionized water until neutral to obtain acidified nano-diamonds.

[0045] b. Put 400g of ball milling / grinding beads with a diameter of 0.08-0.1mm into a ball milling / grinding jar with a volume of 100mL, add 2.0g of acidified nano-diamond, 50g of n-octane, 2.0g of oleic acid, and set The rotating speed of the ball mill / mill is 580r / min, the ball mill / grinding time is 2h, and a clear and transparent black colloidal solution is obtained, which is characterized by dynamic light scattering, and the obtained results are as follows Figure 5 Shown in curve a.

[0046] c. Use a rotary evaporator to remove excess n-octane solvent from the obtained clear and transparent nano-diamond black colloid solution, set the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com