An A-frame rolling machine with a detachable braking device

A braking device, A-frame technology, applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve the problems of difficult disassembly and maintenance, save time, avoid easy collision damage, optimize The effect of the braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

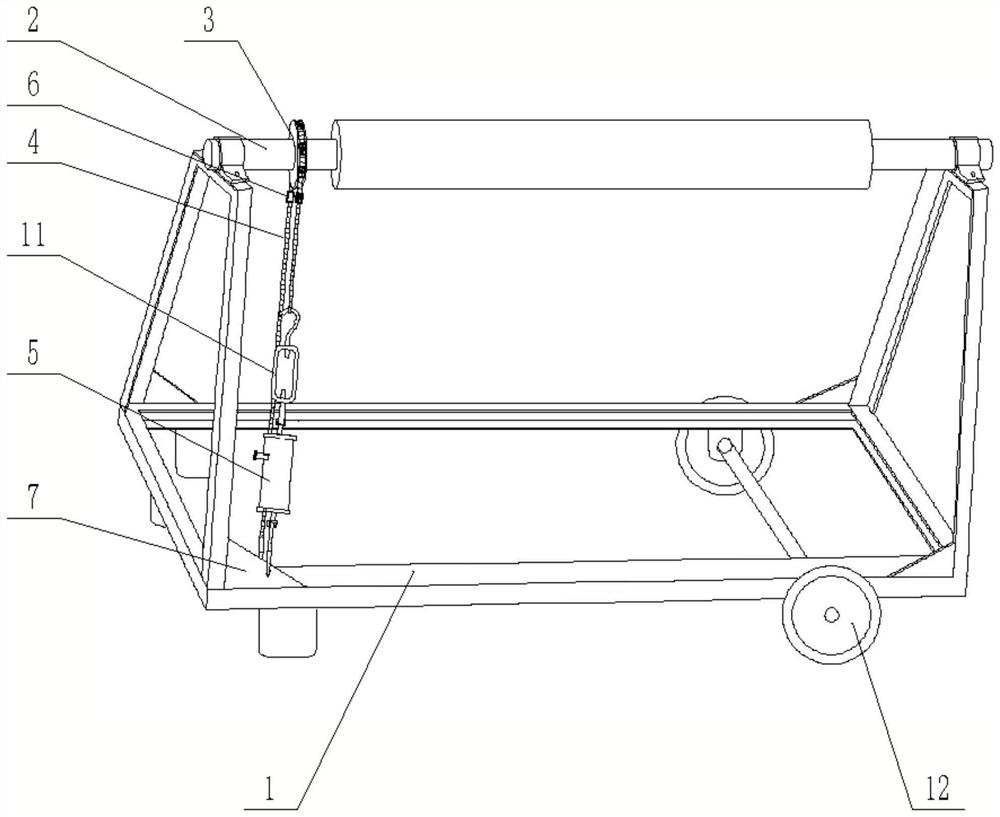

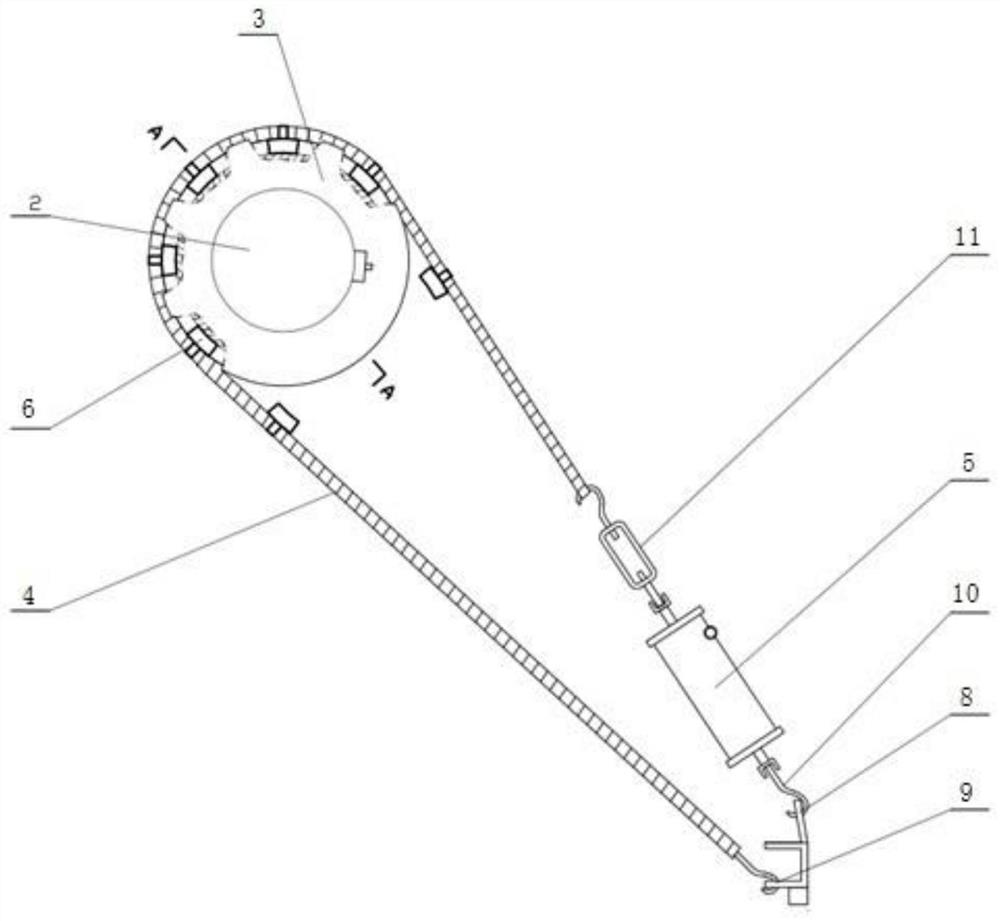

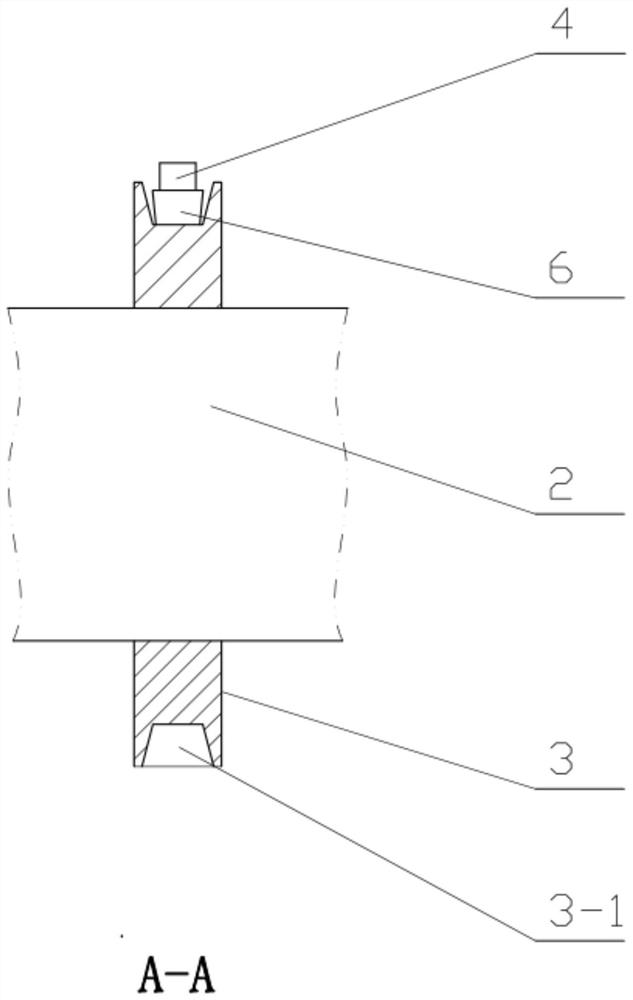

[0027] The scheme of the present invention is as follows: Figure 1-3 As shown, an A-frame rolling machine with a detachable braking device includes a bracket 1, a rotating shaft 2 with a cloth rolling roller, and a braking device; the rotating shaft 2 is installed on the bracket 1, and the manufacturing The moving device includes a friction brake wheel 3, a chain 4 with brake blocks installed, and a tension adjustment cylinder 5. The friction brake wheel 3 is fixedly installed on one end of the rotating shaft 2, and a circle is arranged on the tread surface of the friction brake wheel 3. In the friction groove 3-1, seven brake blocks 6 are arranged on the chain 4 . The side of the bracket 1 and the four corners of the base are fixed by a vertical reinforcing member 7, and the reinforcing member 7 is provided with a first A positioning hole 8, a second positioning hole 9 is opened at the intersection of the lower end surface of the base of the support 1 and the vertical surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com