A Novel Cooling and Heating Car Seat Cushion

A seat cushion and automobile technology, which is applied to vehicle seats, seat heating/ventilation devices, vehicle parts, etc., can solve the problem that the life safety of large truck drivers cannot be guaranteed, and large truck drivers cannot concentrate on driving and heating Device and cooling device installation troubles and other problems, to achieve the effect of reducing large truck accidents, reducing losses, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

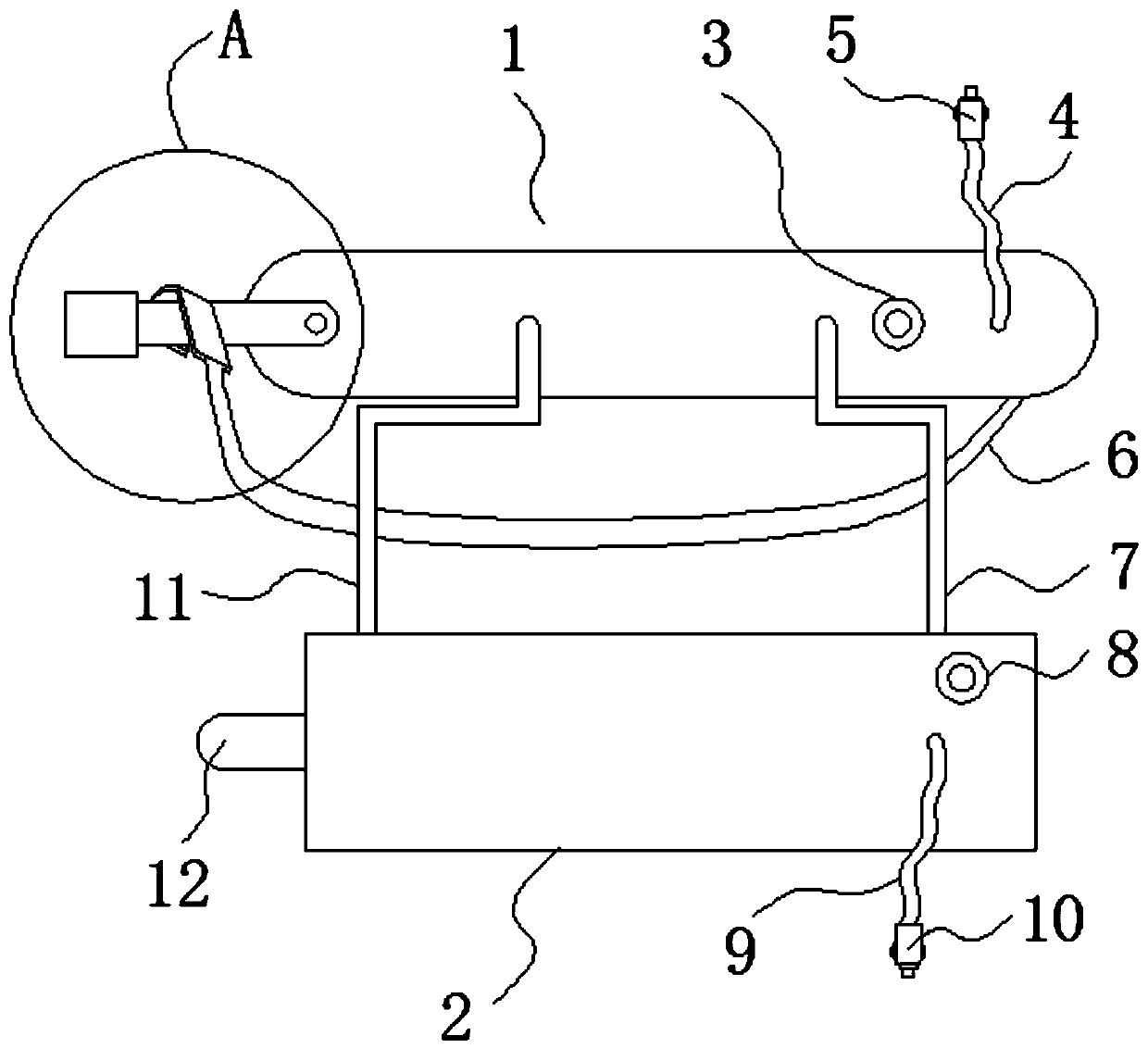

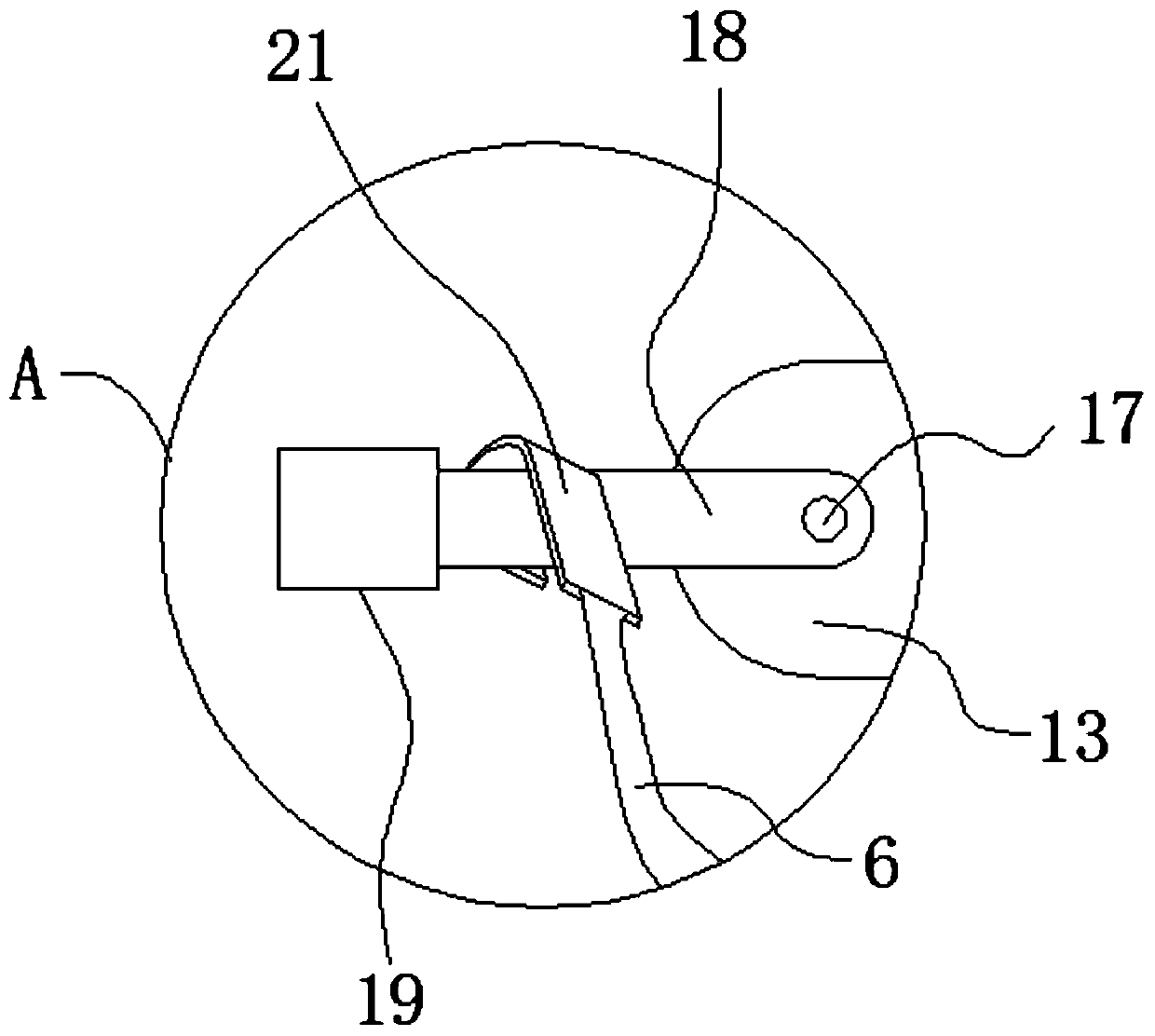

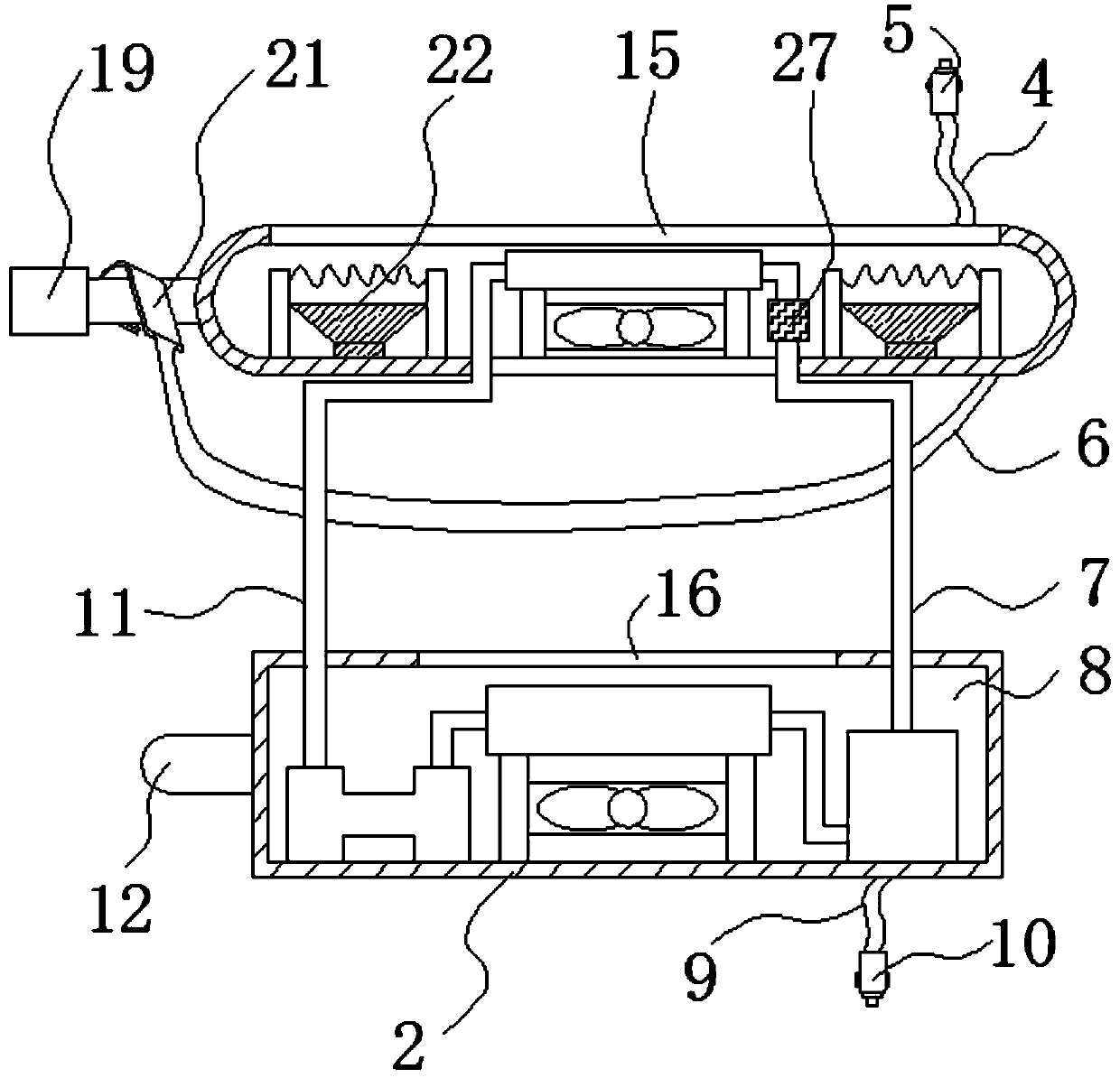

[0047] The following is attached Figure 1-8 The present invention is described in further detail.

[0048] A new cooling and heating car seat cushion, such as Figure 1-8 As shown, it includes a seat cushion body 1 and a chassis 2, the seat cushion body 1 includes a support shell 13, the upper part of the support shell 13 is inlaid with an elastic support plate 15 in the center, and the elastic support plate 15 is evenly opened with Through hole 14, two sets of heating units 22 are arranged symmetrically on both sides of the inside of the support shell 13, and two first stands 29 are vertically installed in the center of the bottom of the support shell 13, and the two first An evaporator 26 is installed on the upper end of the stand 29, and a first fan 28 is fixedly installed below the evaporator 26 between the two first stands 29, and two second fans 28 are installed vertically at the center of the inner bottom of the cabinet 2. Two vertical frames 33, a condenser 31 is in...

Embodiment 2

[0066] The difference from Example 1 lies in the preparation of the elastic support plate 15, and its specific preparation method is as follows:

[0067] Take the following raw materials and weigh them by weight: 90 parts of natural rubber, 60 parts of butyl rubber, 70 parts of methanol, 6 parts of glass powder, 9 parts of quartz powder, 10 parts of epoxy resin, 6 parts of silane coupling agent, terephthalate 3 parts of amine, 4 parts of diethylthiourea, 6 parts of paraffin oil;

[0068] S1. Put the weighed natural rubber and butyl rubber into the internal mixer for banburying. The temperature of the internal mixer is set to 160°C, the speed is set to 750r / min, and the banburying time is 25min to obtain the banburying material ;

[0069]S2, adding the banburying material, methanol, glass powder, quartz powder, epoxy resin, silane coupling agent, p-phenylenediamine, diethylthiourea and paraffin oil prepared in step S1 into a mixer for stirring and mixing, The temperature of t...

Embodiment 3

[0075] The difference from Example 1 lies in the preparation of the elastic support plate 15, and its specific preparation method is as follows:

[0076] Take the following raw materials and weigh them by weight: 100 parts of natural rubber, 70 parts of butyl rubber, 80 parts of methanol, 7 parts of glass powder, 10 parts of quartz powder, 11 parts of epoxy resin, 7 parts of silane coupling agent, terephthalate 4 parts of amine, 5 parts of diethylthiourea, 7 parts of paraffin oil;

[0077] S1. Put the weighed natural rubber and butyl rubber into the internal mixer for banburying. The temperature of the internal mixer is set to 170°C, the speed is set to 800r / min, and the banburying time is 30min to obtain the banburying material ;

[0078] S2, adding the banburying material, methanol, glass powder, quartz powder, epoxy resin, silane coupling agent, p-phenylenediamine, diethylthiourea and paraffin oil prepared in step S1 into a mixer for stirring and mixing, The temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com