Compound type LCP (Liquid-Crystal Polymer) high-frequency high-speed double-sided copper foil substrate and preparation method thereof

A double-sided copper foil, composite technology, used in high-frequency matchers, chemical instruments and methods, and other household appliances, etc., can solve problems such as unsatisfactory performance, shrinkage of holes, and impact on yield, and achieve the lowest production cost. , The effect of reducing loss and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

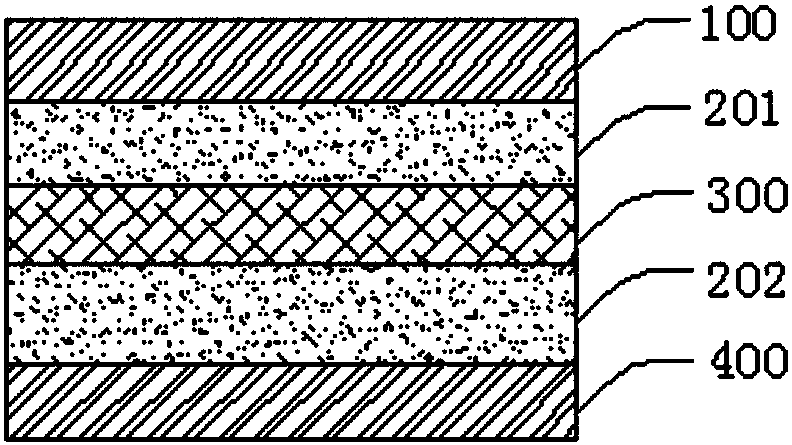

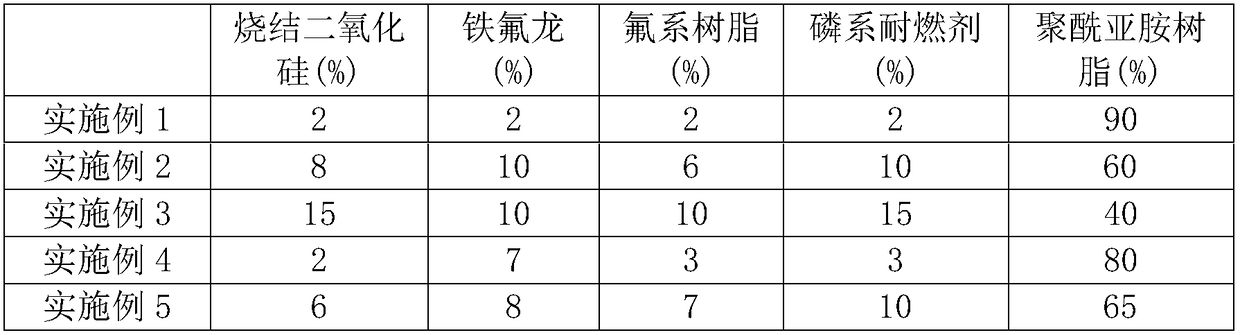

[0050] Embodiment: a kind of composite LCP high-frequency high-speed double-sided copper foil substrate, such as figure 1 with figure 2 As shown, including at least one LCP core layer, at least one very low dielectric adhesive layer and two copper foil layers;

[0051] The LCP core layer and the very low dielectric adhesive layer are located between the two copper foil layers;

[0052] The thickness of each layer of the LCP core layer is 5-50 μm; the thickness of each layer of the ultra-low dielectric adhesive layer is 2-50 μm; the thickness of each layer of the copper foil layer is 1-35 μm.

[0053] Preferably, the thickness of each layer of the LCP core layer is 12.5-50 μm; the thickness of each layer of the ultra-low dielectric adhesive layer is 12.5-50 μm; the thickness of each layer of the copper foil layer is 6-18 μm.

[0054] The double-sided copper foil substrate is one of the following two structures:

[0055] 1. It consists of a layer of LCP core layer 200, a lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hygroscopic ratio | aaaaa | aaaaa |

| hygroscopic ratio | aaaaa | aaaaa |

| hygroscopic ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com