Three-dimensional printing method based on fluid support

A three-dimensional printing and three-dimensional printer technology, applied in the field of three-dimensional printing, can solve the problems of increasing the production time of three-dimensional printing, comprehensive manufacturing cost, limiting the scope of materials, etc., so as to improve the printing yield, reduce the comprehensive cost, and reduce the printing and design experience requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

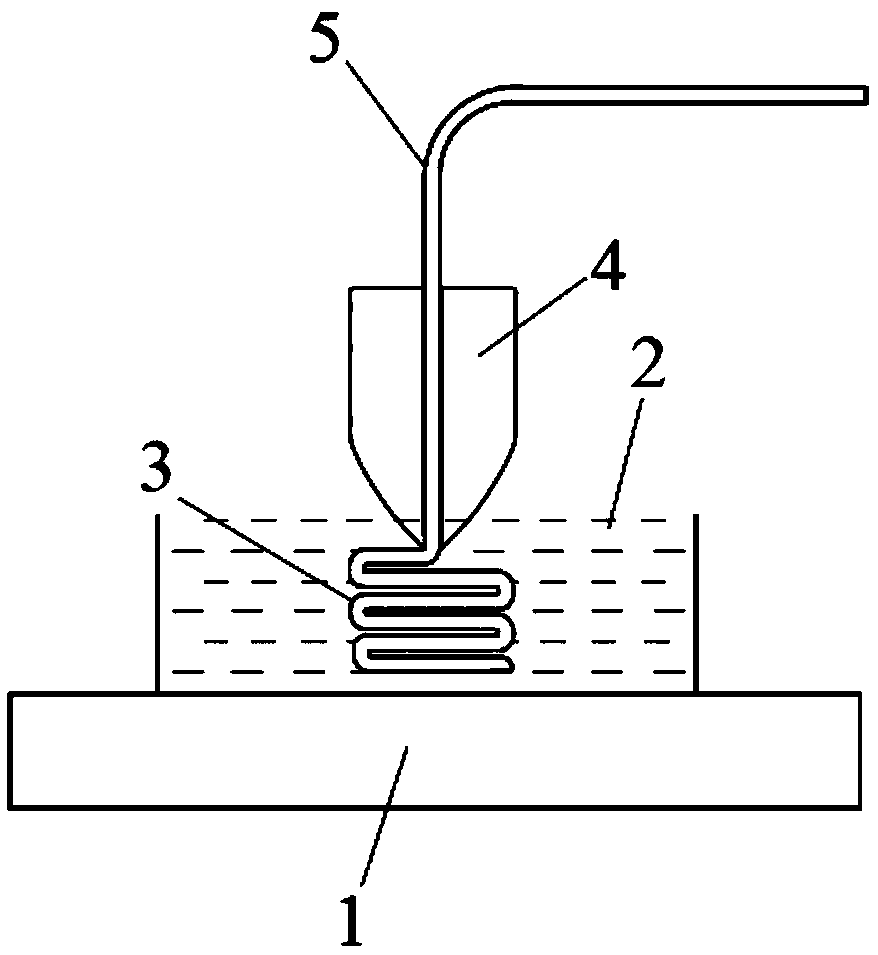

[0033] Step 1. Add 4.7%-5.2% nano-scale hydrophilic silica to the benzyl silicone oil with a viscosity of 50-100cps and a refractive index of 1.460-1.480, and disperse it evenly with planetary stirring. After the stirring is completed, you can get Fluid Support Material 2. It is filled in a glass container 11, and the container 11 is put into a vacuum defoaming machine to remove the air bubbles in the fluid under vacuum conditions for use.

[0034] Step 2: Add a latent curing agent to the epoxy resin and mix it evenly with planetary agitation. After the agitation is completed, the printing material is obtained and poured into the syringe 12 for use.

[0035] Step 3. In this example, a direct-writing 3D printer using air pressure extrusion is used to slice the model 3 to be printed, generate G code, and copy it to the controller of printer 1 with a U disk.

[0036] Step 4. Place the container 11 containing the oily fluid on the platform of the printer 1, execute the G code and...

Embodiment 2

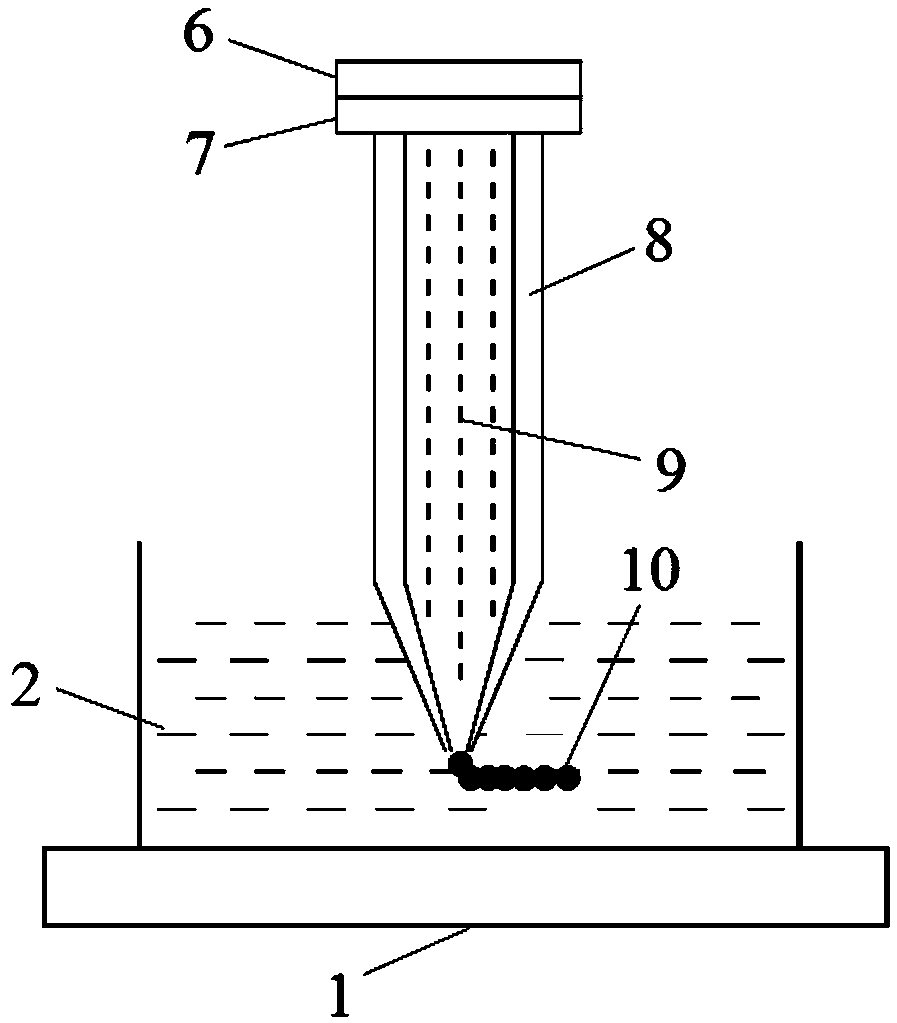

[0040] Step 1: Add 3%-5% magnesium lithium silicate nanopowder to the ultrapure water, disperse it evenly with needle tip ultrasound, and then let it stand for 24 hours until it is stable, and then obtain the supporting fluid 2 .

[0041] Step 2. Addition curing liquid silicone rubber is used to mix the two components, then add thickener and crosslinking retarder, and mix well with planetary stirring. After the stirring is completed, the printing material is obtained and poured into the syringe 12 to be used.

[0042] Step 3. In this example, a direct-writing 3D printer using air pressure extrusion is used to slice the model 3 to be printed, generate G code, and copy it to the controller of printer 1 with a U disk.

[0043] Step 4. Place the container 11 containing the support fluid 2 on the platform of the printer 1, execute the G code and use air pressure control to realize the continuous extrusion of silica gel, so that it can be printed smoothly in the hydrogel fluid and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com