Intelligent printer

A kind of printing machine, intelligent technology, applied in printing machine, rotary printing machine, printing and other directions, can solve the problems of inaccurate color register printing position, inaccurate color registration of finished pattern, affecting the printing yield, etc., to achieve accurate color printing and discharge The effect of convenience and high printing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

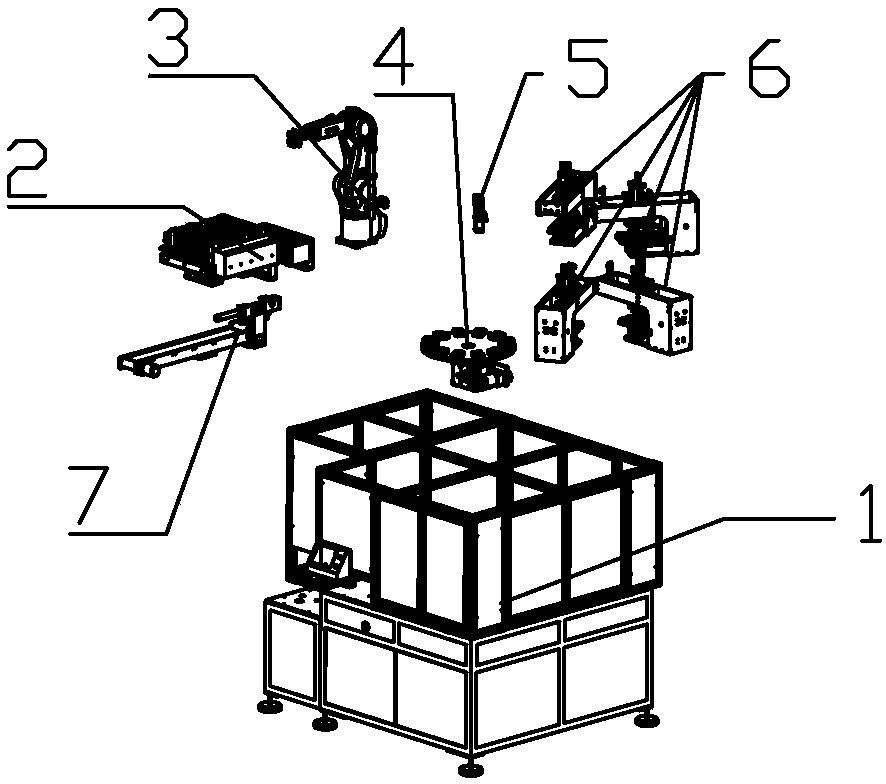

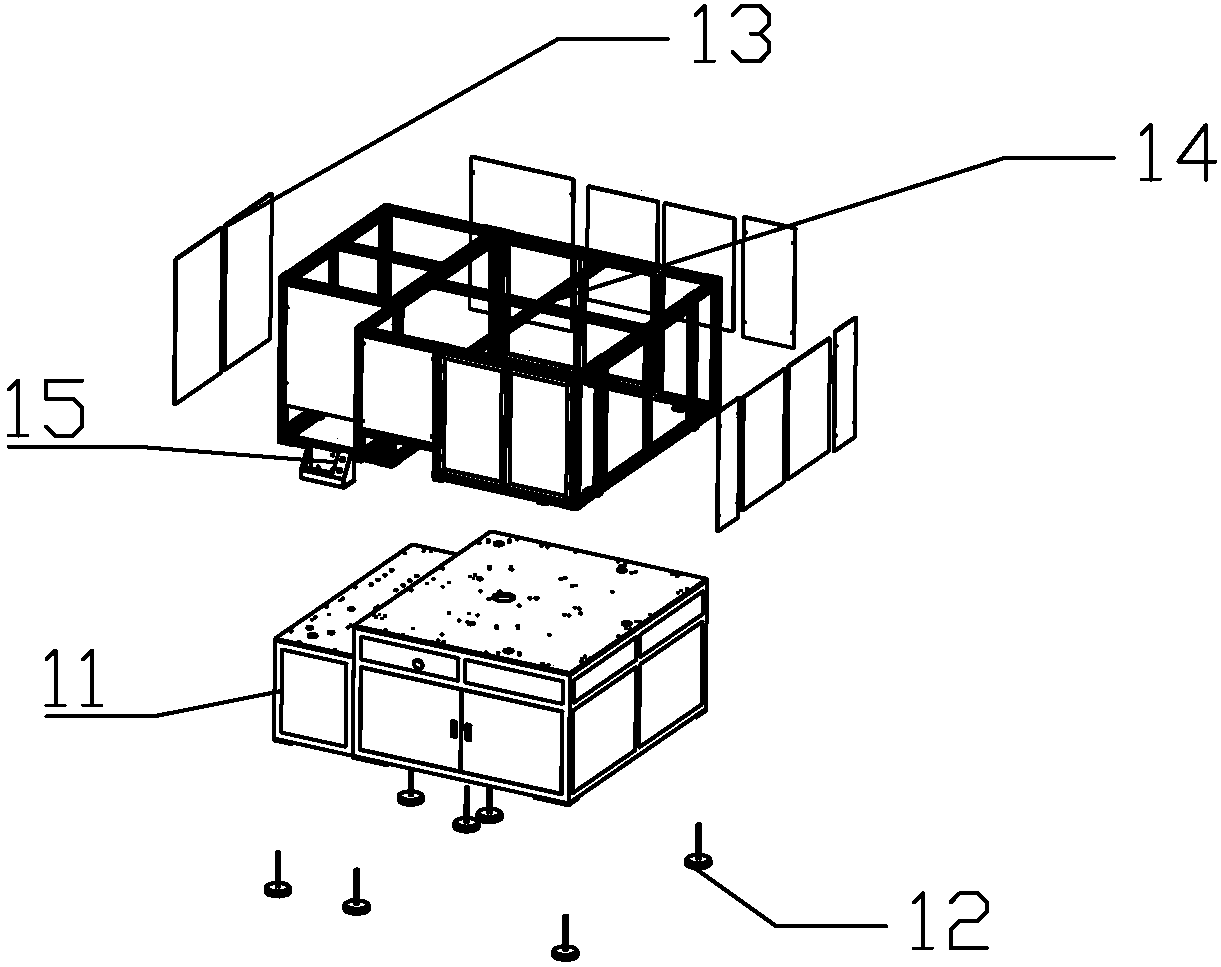

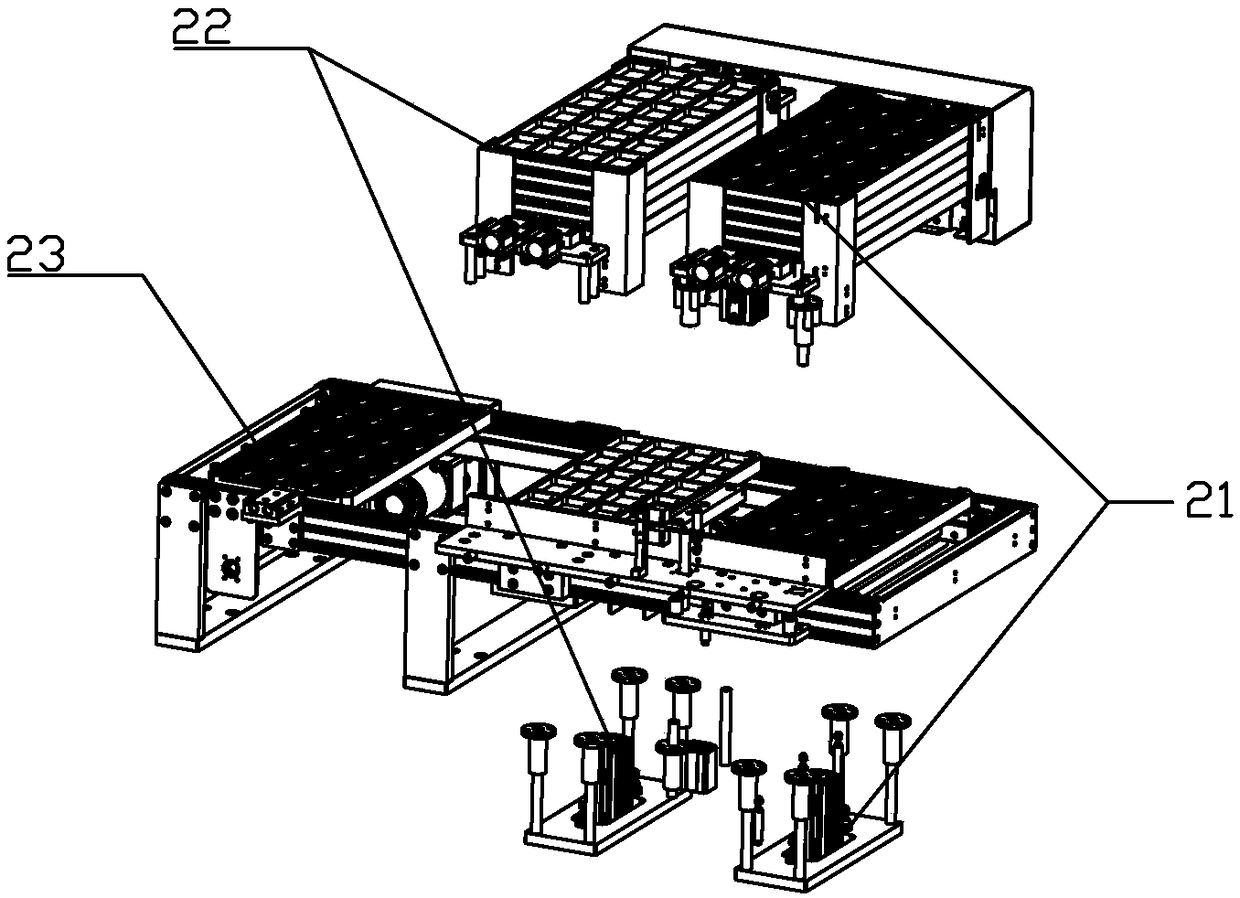

[0042] Combine below Figure 1-Figure 21 The present invention is further described.

[0043] Such as figure 1 and figure 2 The shown intelligent printing machine includes a frame assembly 1 and a tray loading and changing device 2 on it, a manipulator loading device 3, a twelve-degree indexing device 4, a pressing and positioning device 5, a printing device 6 and a product output device. Material device 7. The tray loading and changing device 2 is used for automatically switching the trays. The manipulator feeding device is connected with the material tray loading and changing device 2, and the manipulator feeding device transports the workpieces to be processed in the material tray feeding and changing device 2 to the twelve indexing device 4. The pressing positioning device 5 is connected with the manipulator feeding device 3, and the manipulator feeding device 3 is transported to the workpiece in the twelve indexing device 4 for positioning, which is convenient for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com