A 3D printing laser galvanometer level detection method

A level detection, laser galvanometer technology, applied in the field of 3D printing, can solve problems such as uneven installation of galvanometers and poor printing effects, avoid manual testing, reduce labor costs and testing time, and improve printing yield and work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

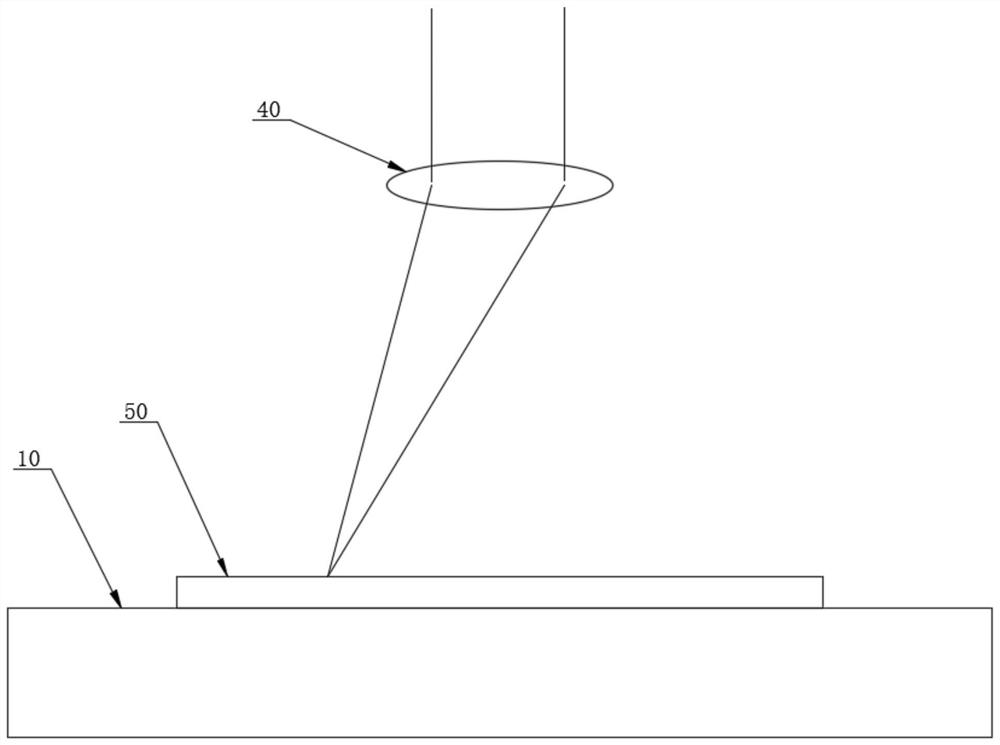

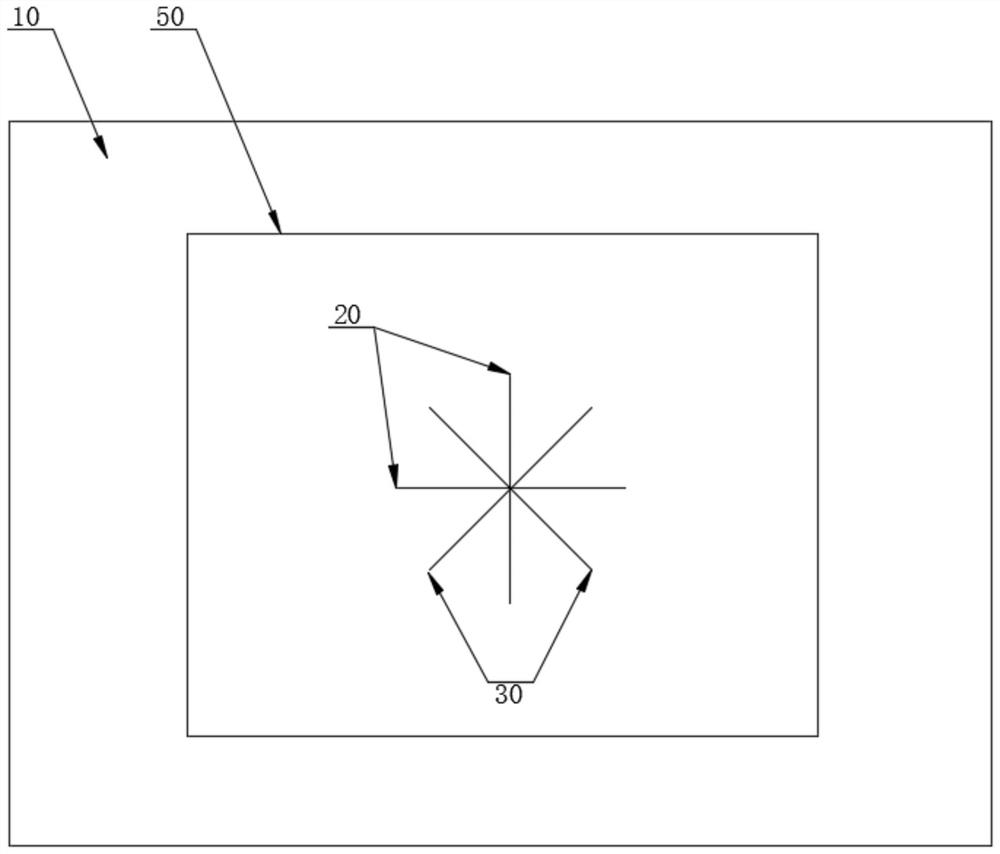

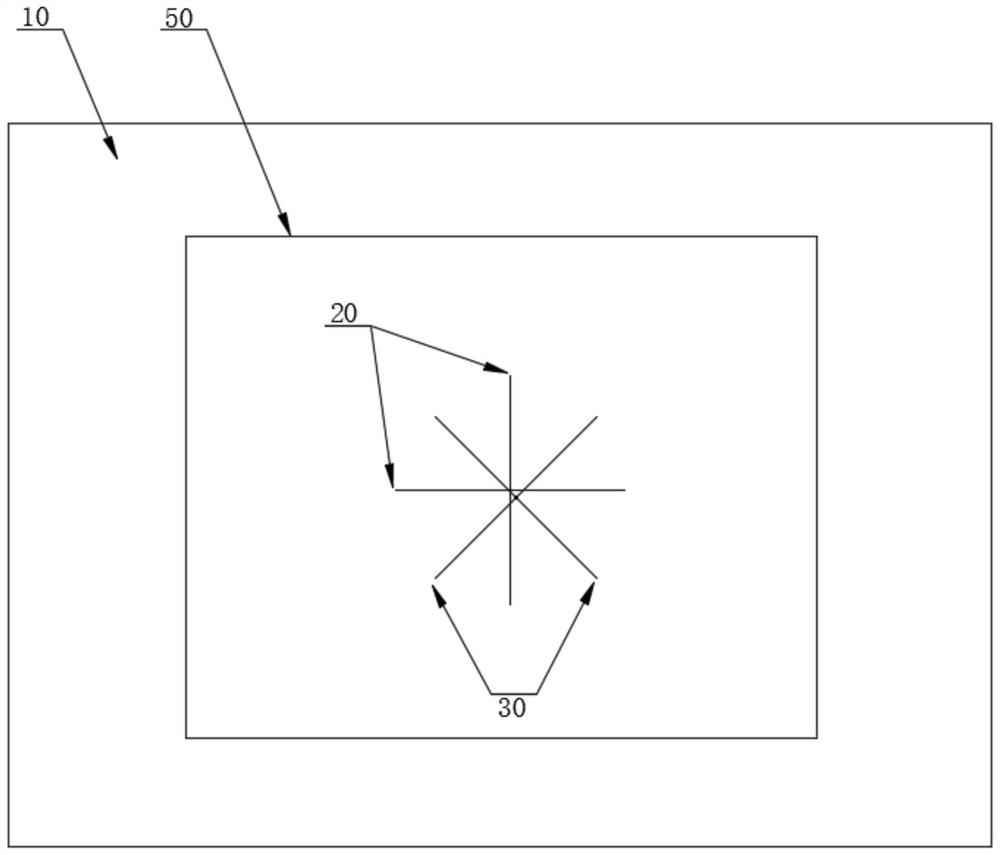

[0022] Such as figure 1 As shown, the present invention provides a method for detecting the level of a 3D printing laser vibrating mirror. The method is based on a powder-spreading 3D laser printing machine, and includes the following steps: S1, confirming that the printing platform 10 is in a horizontal state; S2, establishing cross coordinates, and controlling the laser Print the first cross-shaped track 20 on the printing platform 10; S3, control the cross coordinates to rotate 0-90 °, control the laser to continue printing the second cross-shaped track 30 on the printing platform 10; S4, observe the first cross-shaped track 20 and Whether the intersection points of the second cross-shaped track 30 coincide is to determine whether the vibrating mirror 40 is installed horizontally. Such as figure 2 As shown, when the intersection of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com